Special hot blast furnace for drying shed

A hot blast furnace and drying room technology, applied in the direction of drying gas arrangement, drying, dryer, etc., can solve the problems of slow temperature rise, high energy consumption, short service life, etc., achieve fast temperature rise, low energy consumption, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

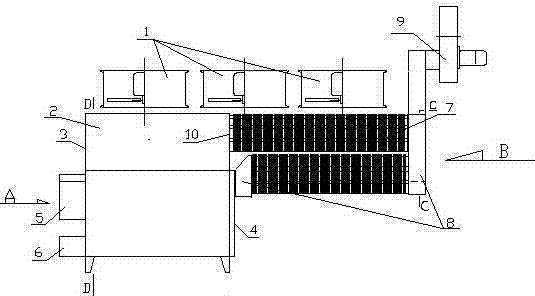

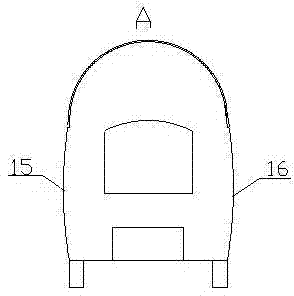

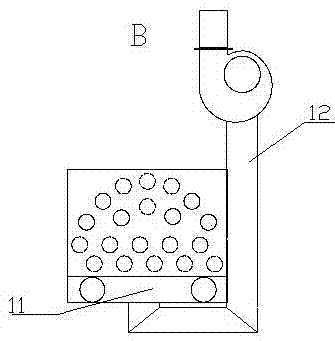

[0012] exist figure 1 Among them, the dedicated hot blast stove for drying room consists of a combustion chamber (1) and a finned tube heat exchanger (7). It is characterized in that the top of the combustion chamber (1) is an arched furnace roof (2) made of steel coils. , the left side plate (15), the right side plate (16), the front plate (3), the rear plate (4) and the fire net (18) connected by the edge of the arched furnace roof (2) constitute the combustion chamber (1), the fire Between the net (18) and the bottom plate (20) is the ash box (19); close to the inner side of the left side plate (15), the right side plate (16), the front plate (3), and the rear plate (4) to build fire-resistant The brick furnace lining (14) is provided with a secondary air duct (13) between the ash box (19) and the combustion chamber (1), so that after the air enters the ash box (19) from the ash cleaning port (6), part of the air It will enter the upper part of the combustion chamber (1) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com