Manufacturing technique of fan foot stand

A manufacturing process and stand technology, which is applied in the manufacturing process of fan stand parts, can solve the problems of high material consumption, high product cost, and high labor cost, and achieve the effect of simple steps and quick cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

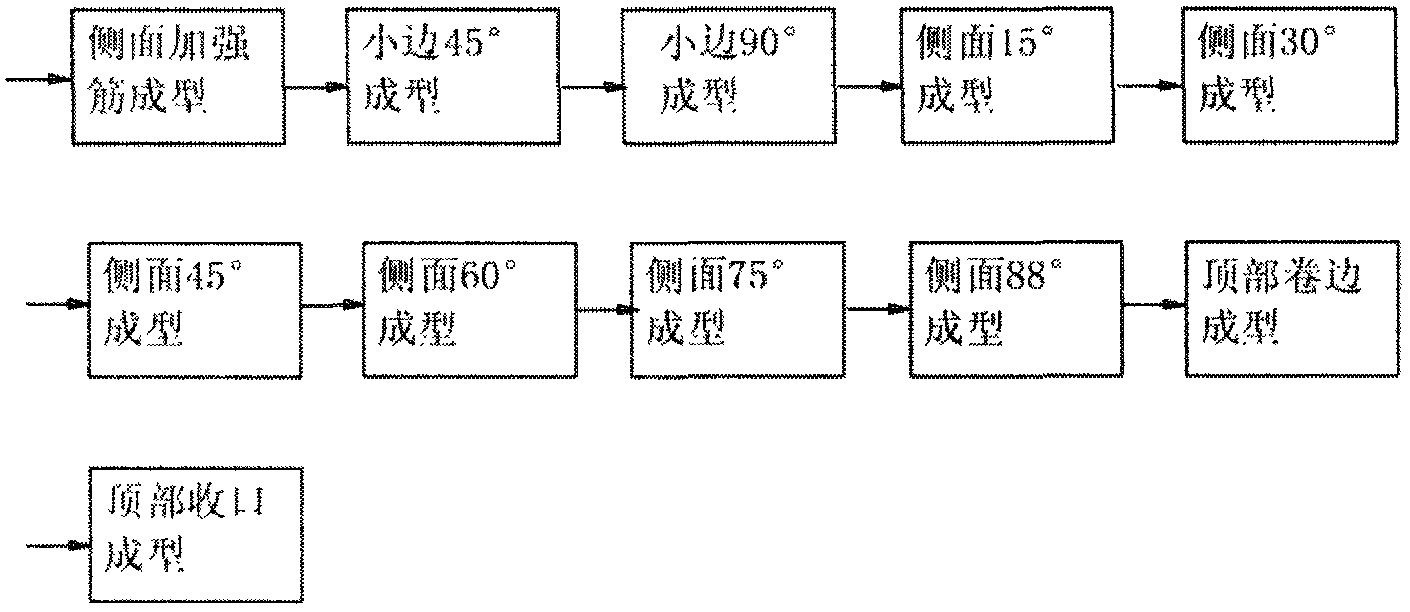

[0035] Example: such as Figure 1 to Figure 15 Shown, a kind of manufacturing process of fan foot frame component is characterized in that: comprising the following process steps,

[0036] 1) Prepare a rectangular block metal material; it can be iron material or other metal material.

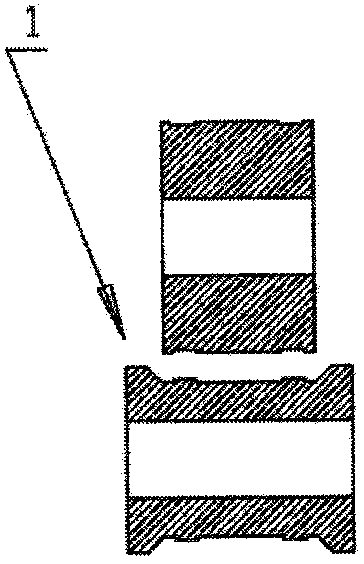

[0037] 2) Use two matching side reinforcement rib rolling wheels 1 to form reinforcement ribs near the edges on both sides of the block metal material;

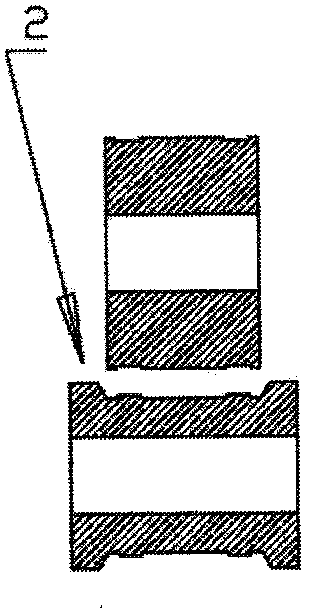

[0038] 3) Use two matching small sides to roll the 45° rolling wheel 2 to roll the edges on both sides of the block metal material, so that the edges on both sides of the metal material form small sides, and the two small sides are respectively bent toward the center of the same surface. Fold 45°;

[0039] 4) Use two matching small sides to roll 90° rolling wheel 3 to continue rolling the edges on both sides of the block metal material, so that the two small sides are respectively bent toward the center of the same surface by 90°;

[0040] 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com