Thin plate crimping device and use method thereof

A thin plate rolling and thin plate technology is applied to a thin plate hemming device and its application field, which can solve the problems of unsuitability and high labor intensity, and achieve the effects of convenient operation, low cost and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

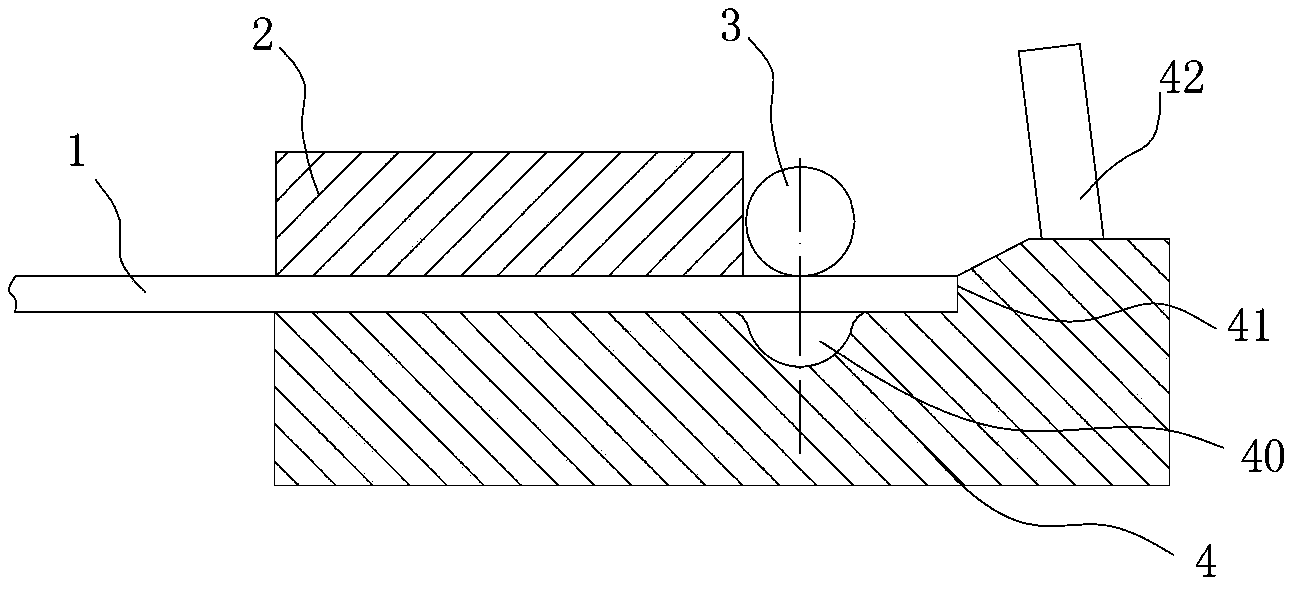

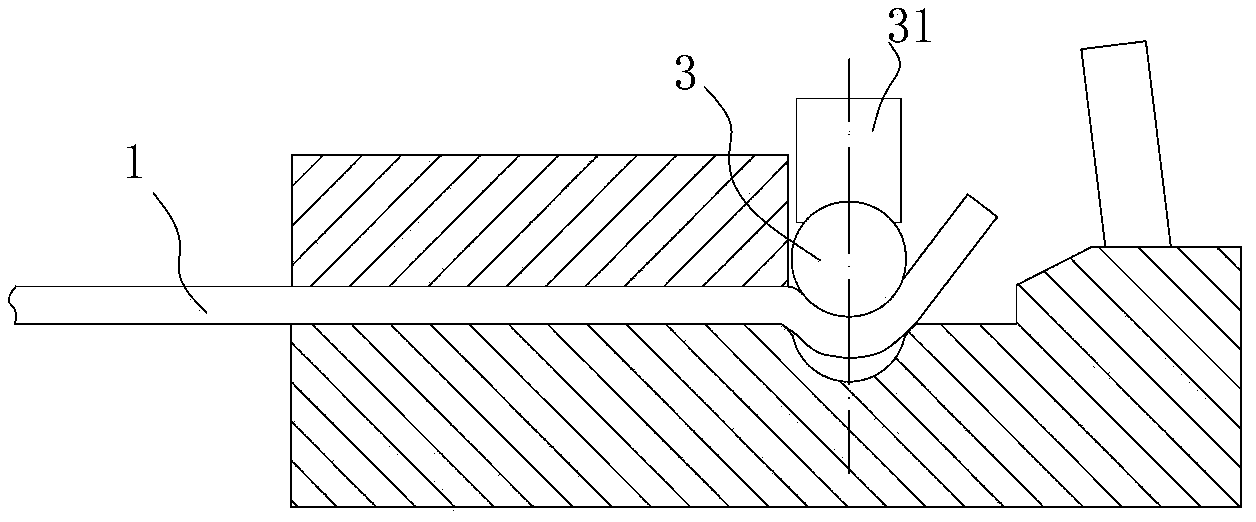

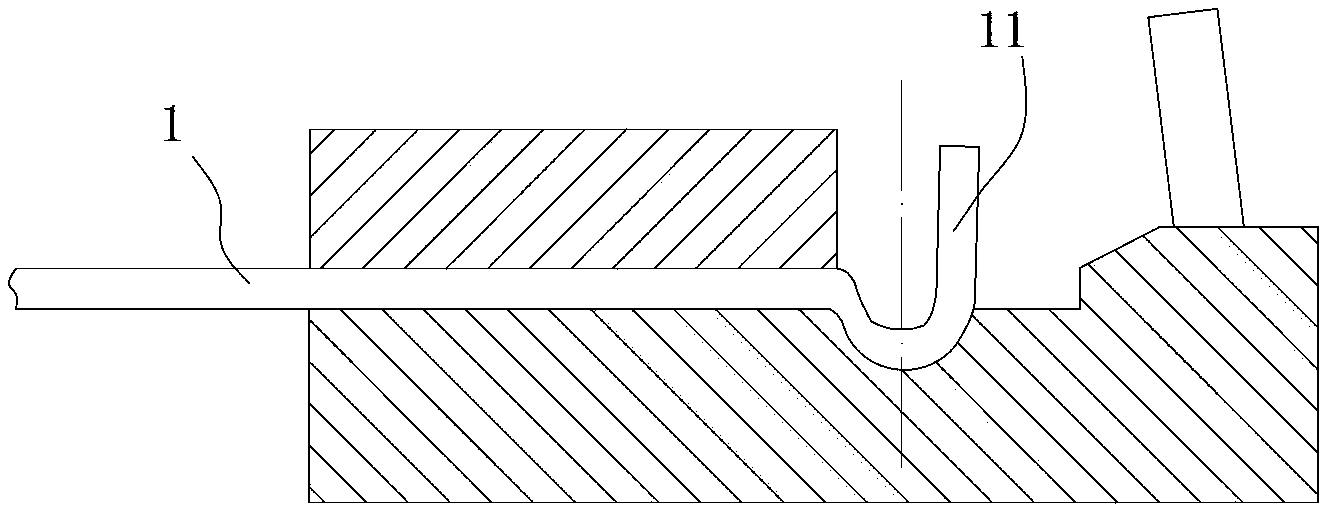

[0018] The present invention as Figure 1-4 Shown: includes seat plate 4, pressure plate 2 and flanging roller 51; The edge of described seat plate 4 is provided with positioning boss 41, and the inner side of positioning boss 41 is provided with the groove 40 that section is semicircle; The flanging roller 51 is movably connected on the positioning boss 41, and the flanging roller 51 includes a roller body, a driving screw 5 and a fixing seat 42; the fixing seat 42 is fixedly connected on the positioning boss 41, The fixing seat 42 is provided with a threaded hole, the driving screw 5 is connected to the threaded hole, and the end of the roller body is connected to the end of the driving screw 5 .

[0019] Using method of the present invention, also need adopt mandrel one 3 and mandrel two 32, the diameter of described mandrel one 3 is greater than the diameter of mandrel two 32; Then, use according to the following steps:

[0020] 1) Place the thin plate 1 on the seat plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com