Double-faced sloping grain thread rolling die

A technology of double-sided twill and thread rolling board, which is applied to threaded products, other household appliances, household appliances, etc., can solve the problems of waste, poor bolt quality, and affect the bolt processing effect, so as to increase the service life and ensure quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

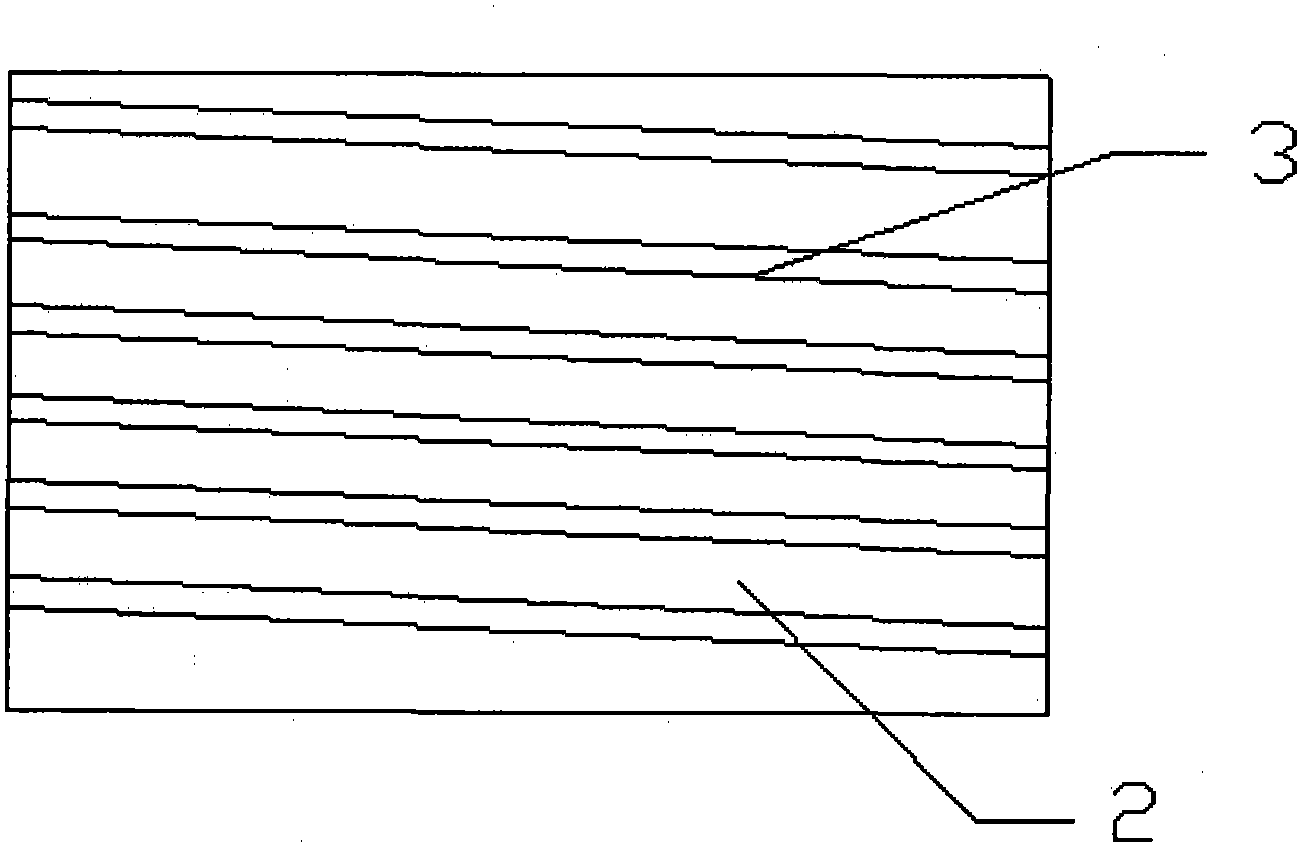

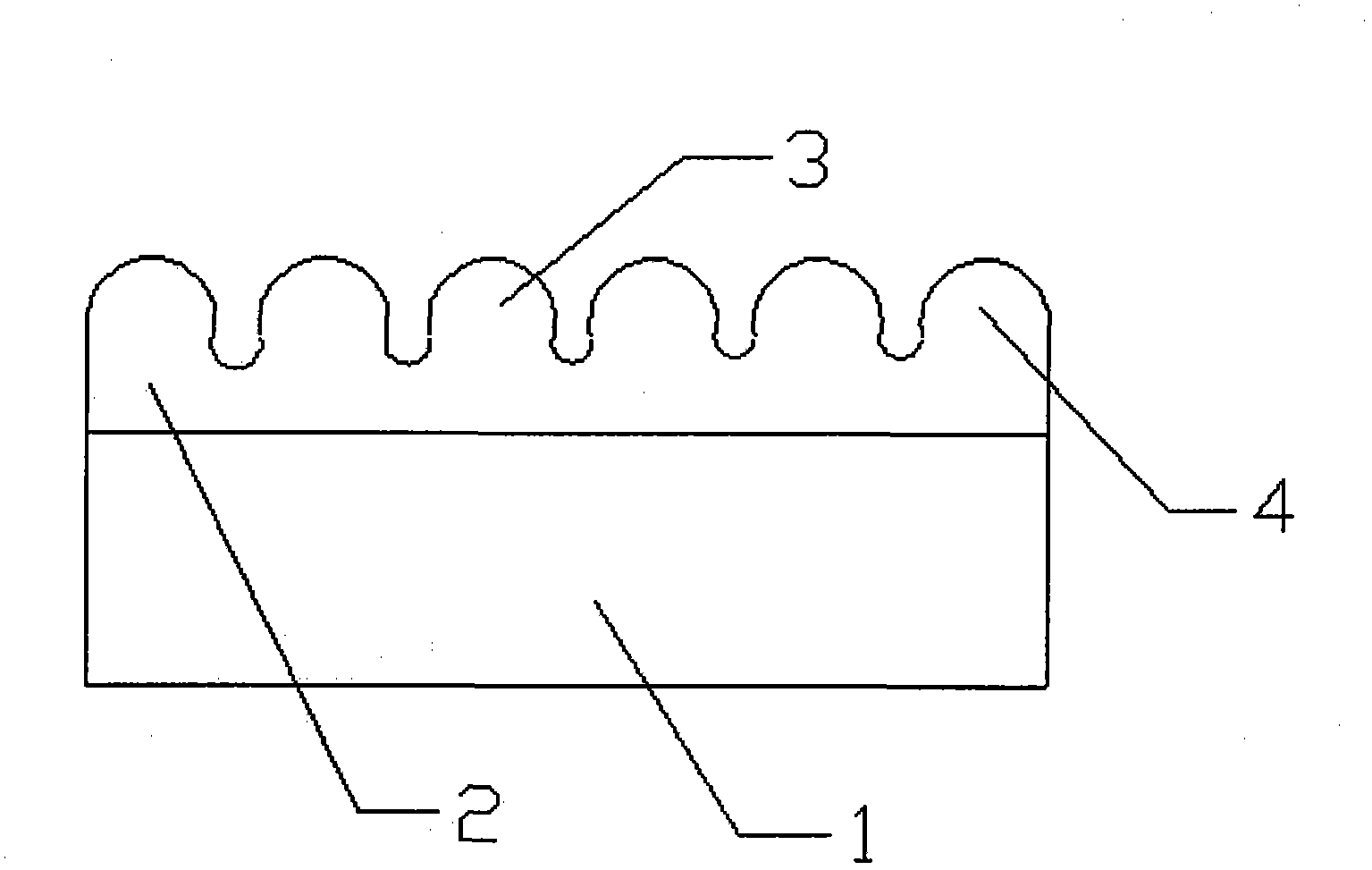

[0016] see figure 1 and figure 2 , the double-sided twill thread rolling board of the present invention comprises a base plate 1, the material of the base plate 1 is high-speed steel, the top and bottom of the base plate 1 are provided with a thread rolling surface 2, and the two thread rolling surfaces 2 are provided with There are tooth lines 3, the tooth lines 3 are twill lines, and there is at least one tooth line 3, and a waste chip groove 4 is arranged between the adjacent two tooth lines 3.

[0017] The double-sided twill thread rolling plate of the present invention is provided with a waste chip groove 4, which can collect redundant waste chips generated in the process of processing, thereby ensuring the quality of the bolt; two thread rolling surfaces 2 can be used in turn, increasing the efficiency of the thread rolling plate. service life.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap