Servo motor cable

A servo motor and cable technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of easy entanglement of power lines and encoders, large total volume of cables, and high production costs, so as to reduce the production process , reduce the volume, facilitate the effect of laying construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

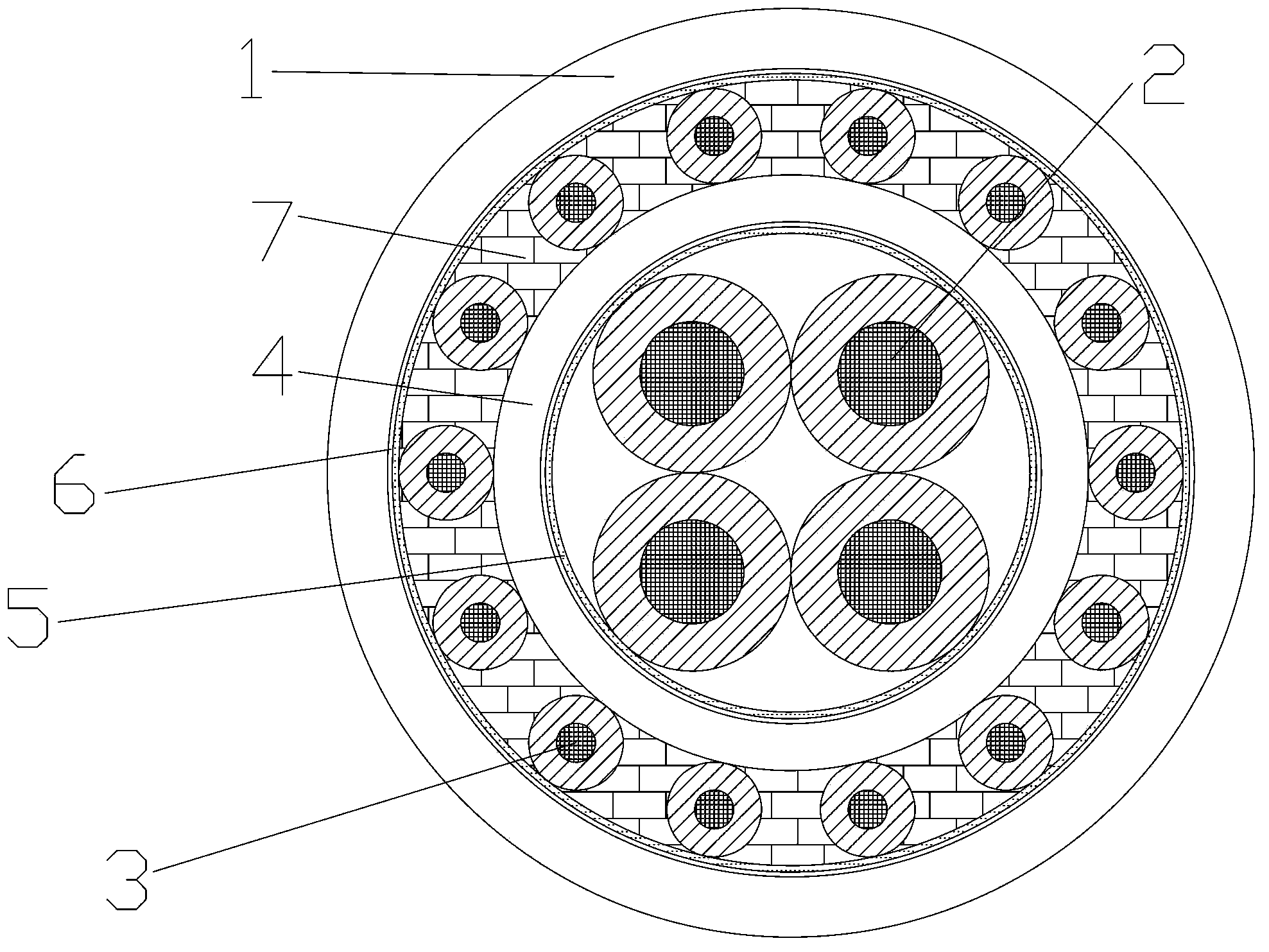

[0017] Such as figure 1 As shown, the servo motor cable of the present invention includes a power line 2 , an encoder feedback line 3 , an inner sheath 4 , an outer sheath 1 , a first shielding layer 5 and a second shielding layer 6 .

[0018] Wherein, the power cord 2 includes a core wire, an insulating layer and a shielding net, and the insulating layer and the shielding net are sequentially coated on the outside of the core wire. The insulation layer is wrapped around the outside of the core wire to play the role of insulation protection. The shielding net plays the role of shielding protection, initially avoiding the interference of electromagnetic waves on it, and also preventing the leakage of electromagnetic wav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com