Method for forming metal pin of switch and metal pin of switch

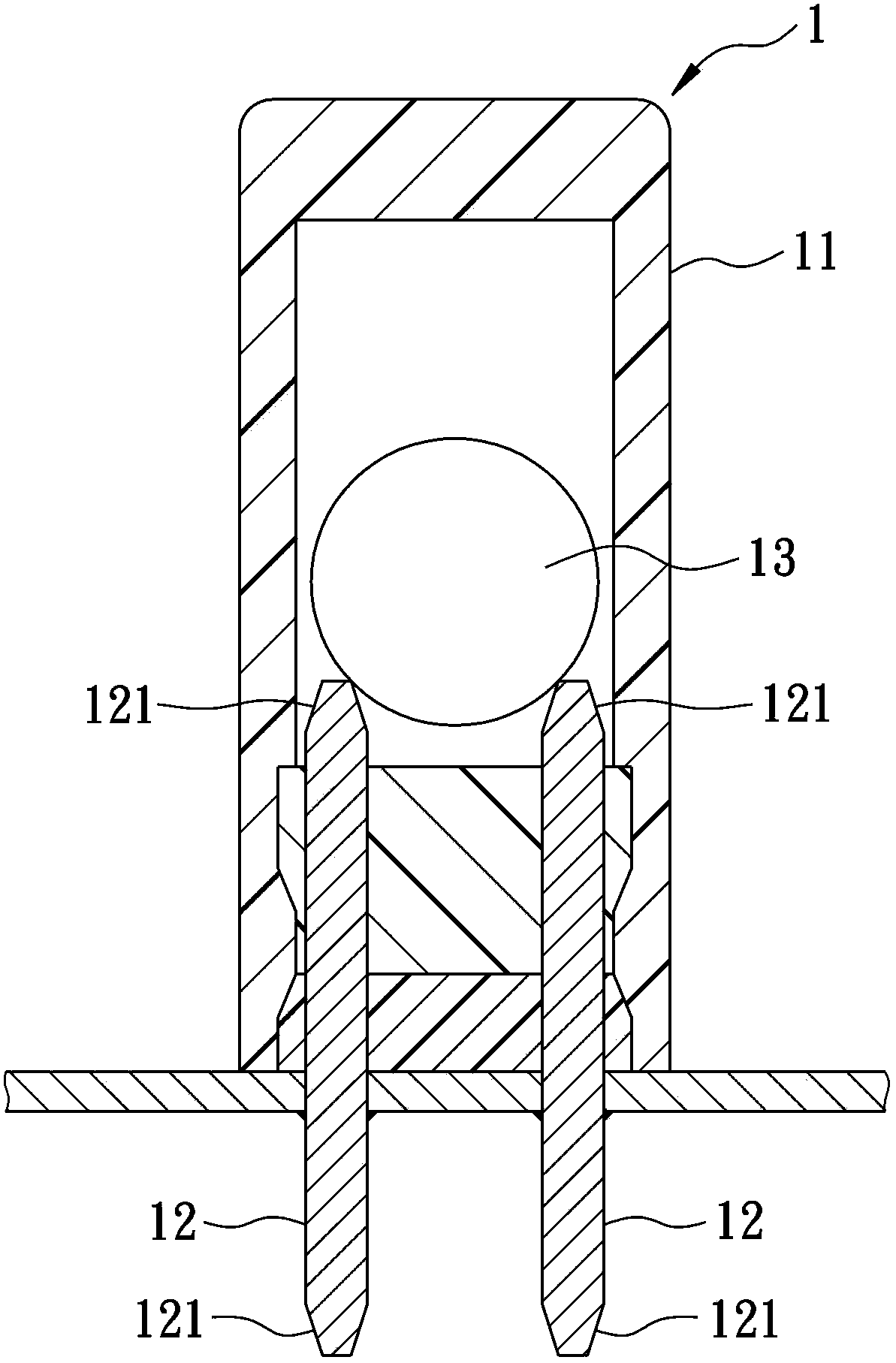

A molding method and switch technology, applied in the direction of electric switches, contact electrical connections, electrical components, etc., can solve the problems of easy failure and affecting the contact area of balls 13, so as to improve the conduction effect, improve the simplicity and convenience, The effect of improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

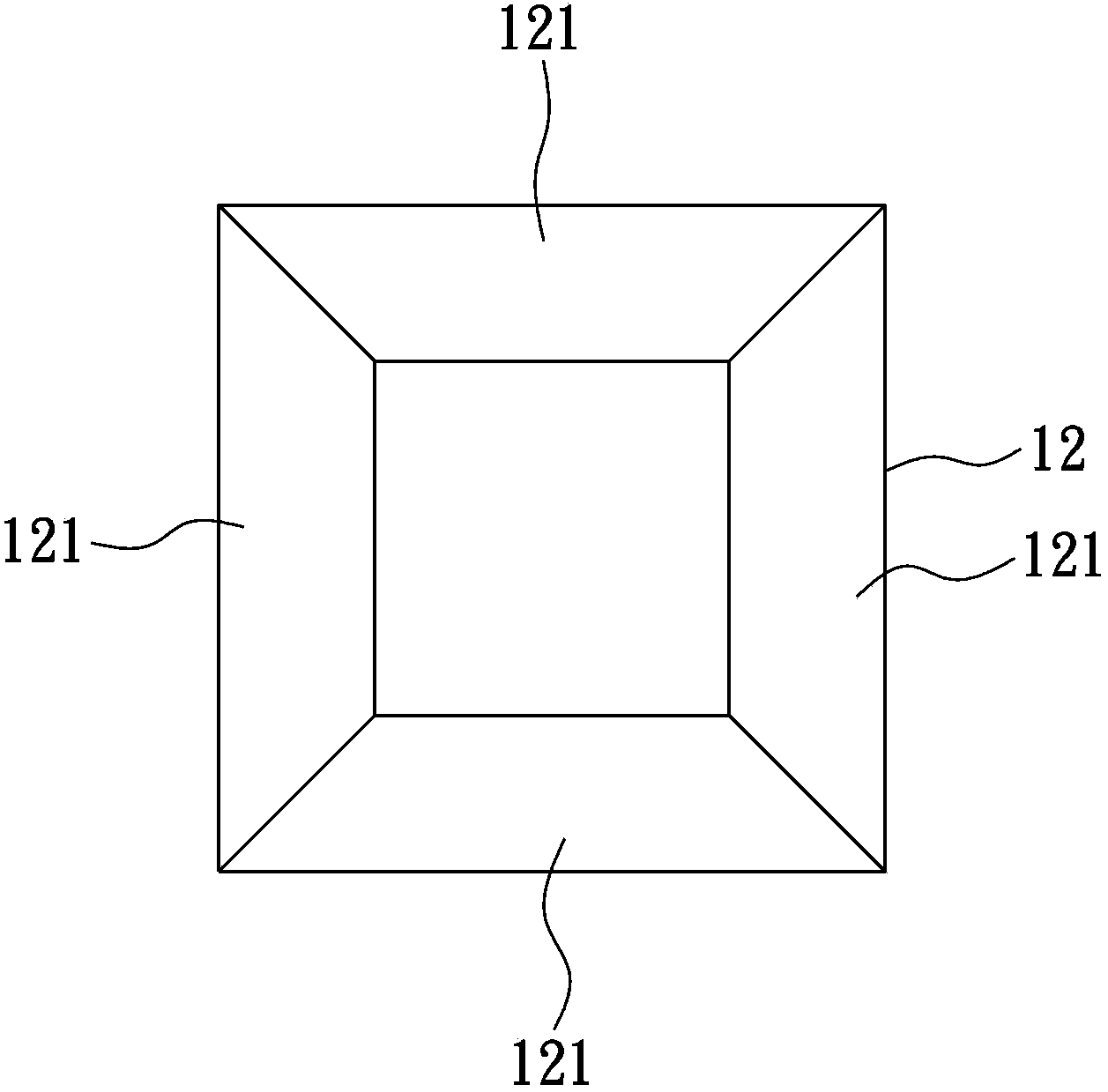

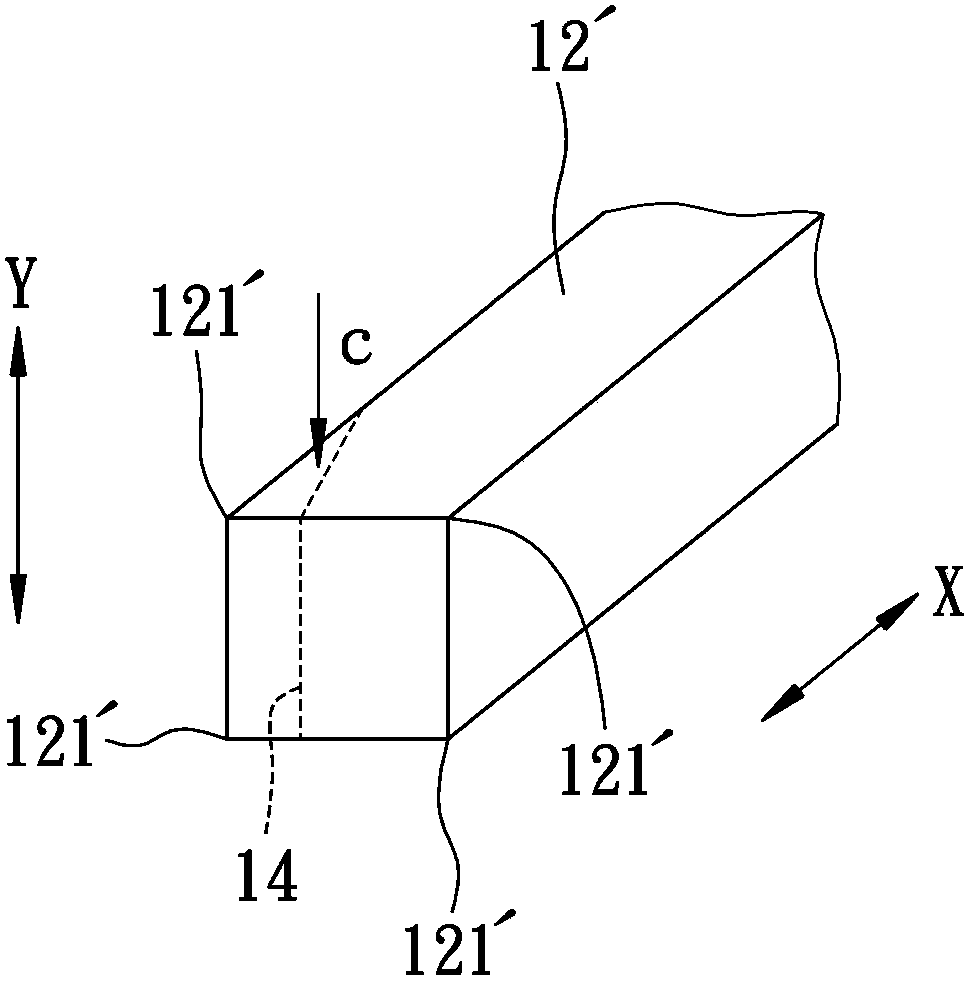

[0032] refer to Figure 5 , Image 6 and Figure 8 , a first preferred embodiment of the metal pin 2 of the switch of the present invention, the metal pin 2 is elongated and includes a contact portion 201 and a connecting portion 202 extending integrally with the contact portion 201, the contact portion 201 has four 21 end angles.

[0033] The metal pin 2 defines a long-axis direction X and a short-axis direction Y perpendicular to the long-axis direction X along the long direction, wherein the short-axis direction Y is parallel to two sides of the cross-section of the metal pin 2 , the direction perpendicular to the other two sides of the cross section.

[0034] Each end angle 21 of the aforementioned contact portion 201 is stamped and formed to form an end angle mold roll area I with a smooth arc surface, and the depth t of the end angle mold ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com