Control method for metering the quantity of dampening medium

A quality, measuring instrument technology, used in general parts of printing machinery, printing, printing presses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

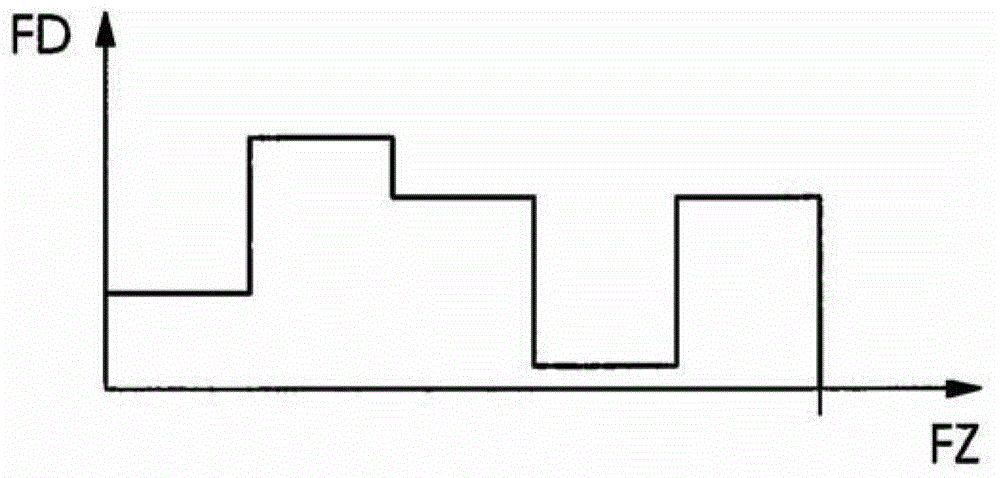

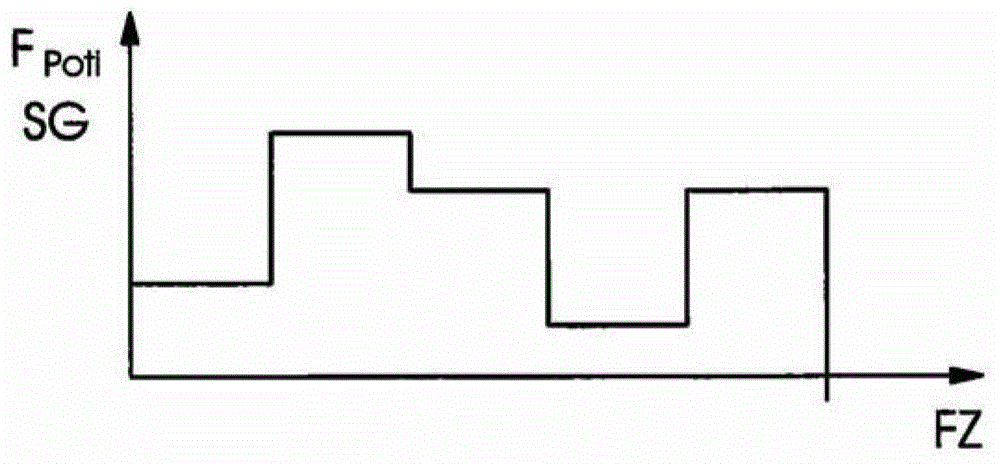

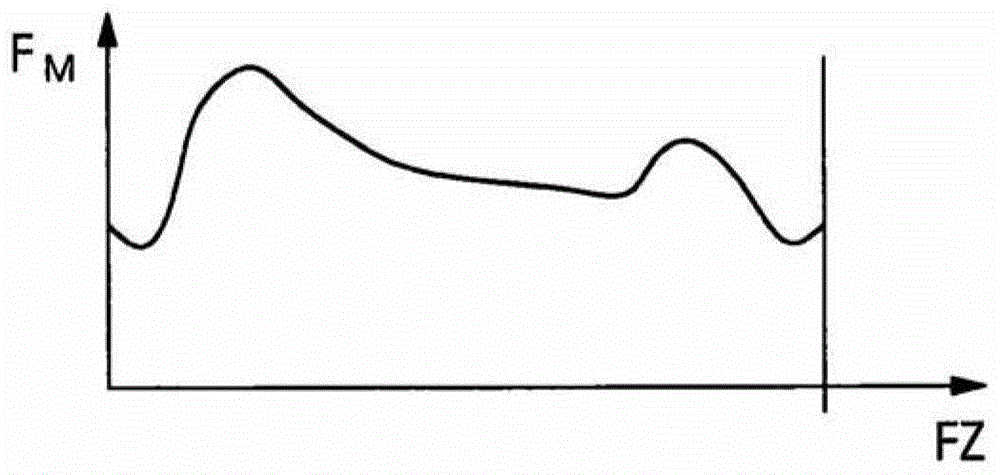

[0027] The new knowledge used in the present invention is that the measured ink density DV in the printed image and the measured amount of wetting medium F M F Poti Has a fixed association. For this purpose, certain inspection elements are used on the printed board in the printing machine, which inspection elements have corresponding dependencies. Such inspection elements can be produced in different ways. For example, a coating can be applied to the ink-guiding layer of the printing plate or the ink-guiding layer of the printing plate can be modified, for example, by partial removal. In addition, a coating layer can be applied to the ink-free non-printing area of the printing plate or the non-printing area of the printing plate that guides the wetting medium can be modified. It is also possible to apply a foil with desired characteristics on the surface of the printing plate. In addition, the roughness or height of the water or ink guiding layer on the printing plate ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com