Automatic fluid metering device for tight sandstone relative permeability experiment and use method of automatic fluid metering device

An automatic metering and tight sandstone technology, which is applied in the directions of surveying, earthwork drilling and production, wellbore/well components, etc., and can solve the problems of unacceptable metering error and less liquid phase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

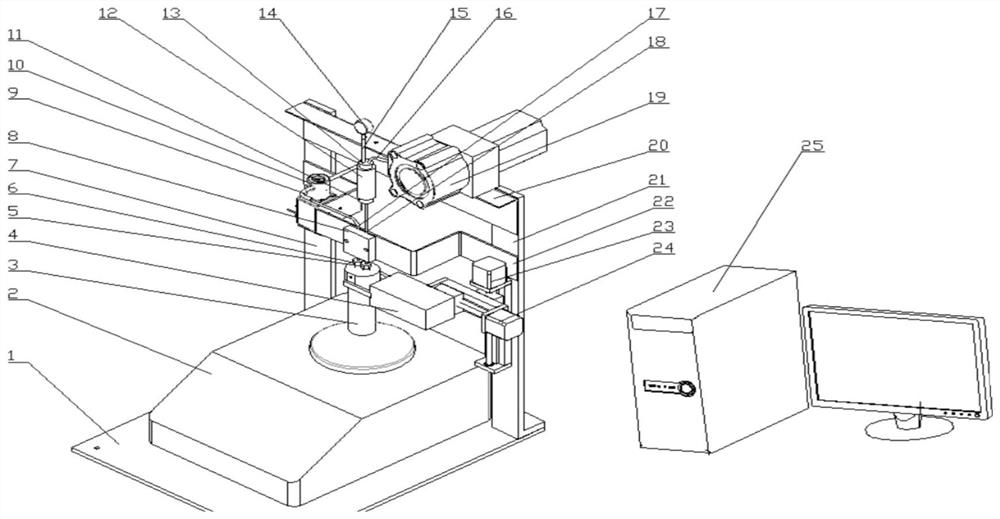

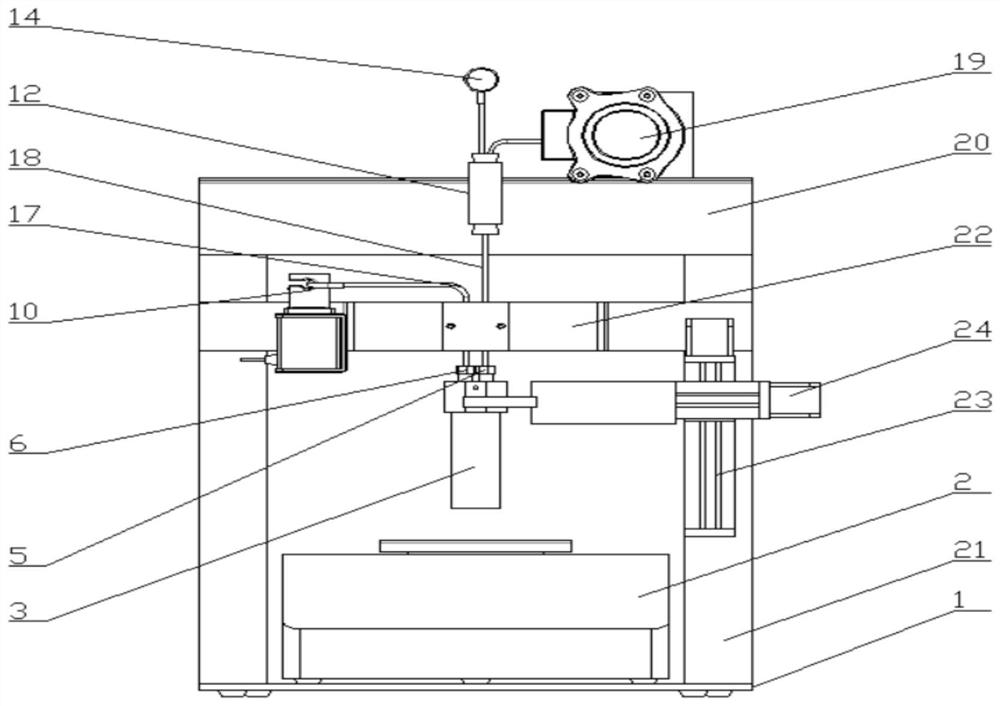

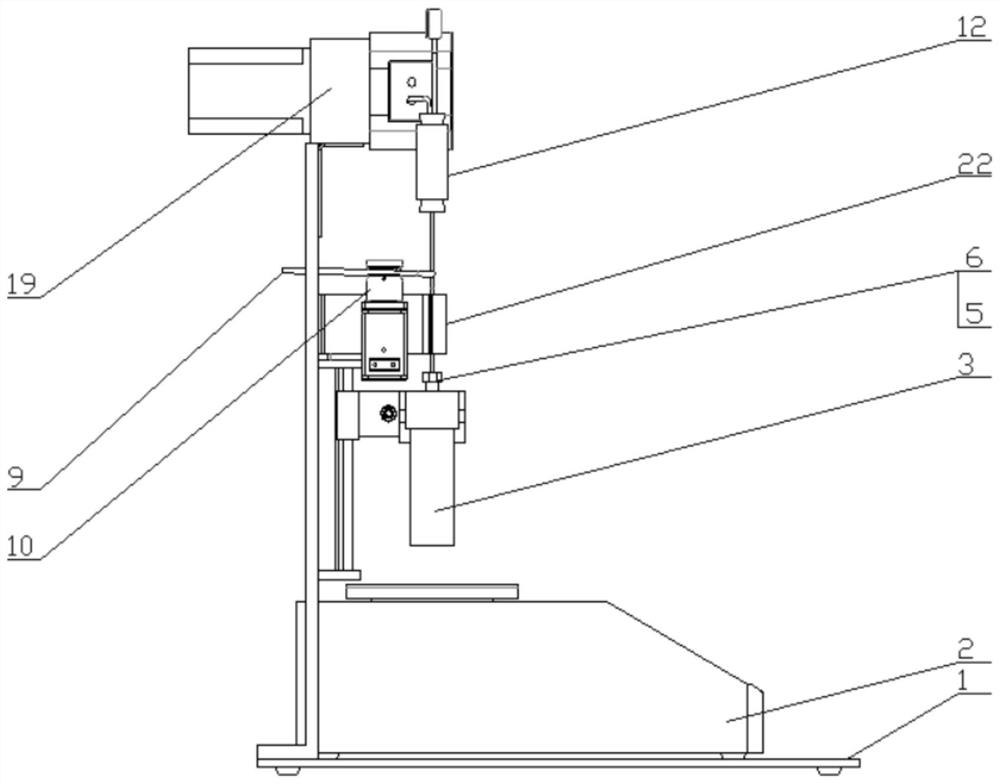

[0025] An automatic fluid metering device for tight sandstone phase permeability experiments, including a base plate 1, a balance 2, a micro-pressure sensor 14, a gas metering pump 19 and a data acquisition system 25,

[0026] The balance 2 is arranged on the upper surface of the bottom plate 1, and the left column 7 and the right column 21 are respectively fixed on the bottom plate 1 on both sides of the balance 2. The head end of the left column 7 and the head end of the right column 21 are connected by a beam 20, and the gas metering The pump 19 is installed on the crossbeam 20. A pipeline fixing frame 22 is arranged between the left column 7 and the right column 21 below the beam 20. The pipeline fixing frame 22 adopts a U-shaped structure. The drying bottle inlet pipe 17 and the drying bottle outlet pipe 18, the drying bottle 3 is arranged directly below the drying bottle inlet pipe 17 and the drying bottle outlet pipe 18, and a through hole is provided on the drying bottl...

Embodiment 2

[0028] On the basis of Embodiment 1, a Y-axis mechanical arm 23 is also installed in the middle of the right column 21. The Y-axis mechanical arm 23 can move along the vertical direction, and an X-axis mechanical arm 24 is slidably installed on the Y-axis mechanical arm 23. The X-axis mechanical arm 24 can move along the horizontal direction, and the movable end of the X-axis mechanical arm 24 is equipped with a manipulator 4. The manipulator 4 is used to grab the drying bottle 3, so as to realize that the grabbing drying bottle 3 is inserted upward into the drying bottle inlet pipe 17 and drying bottle outlet pipe 18, or pull down to break away from drying bottle inlet pipe 17 and drying bottle outlet pipe 18, and place the purpose on the balance.

[0029]A first pinch valve 8 and a second pinch valve 10 are arranged on the pipeline fixing frame 22, and the first pinch valve 8 is installed in the middle part of the U-shaped structure of the pipeline fixing frame 22 for connect...

Embodiment 3

[0031] On the basis of Embodiment 2, an inlet self-sealing pressure cap 6 and an outlet self-sealing pressure cap 5 are respectively arranged on the through holes of the drying bottle 3, and a central hole is provided on the inlet self-sealing pressure cap 6 and the outlet self-sealing pressure cap 5, and the inlet The central hole of the self-sealing pressure cap 6 is arranged opposite to the inlet pipe 17 of the drying bottle, and the central hole of the outlet self-sealing pressure cap 5 is arranged opposite to the outlet pipe 18 of the drying bottle.

[0032] The lower plug 11 of the air chamber is arranged at the inlet end of the buffer air chamber 12, the outlet end of the outlet pipe 18 of the drying bottle penetrates the lower plug 11 of the air chamber and extends into the buffer air chamber 12, and an air chamber is arranged at the outlet end of the buffer air chamber 12 The upper plug 13, the micro-pressure sensor pressure introduction pipe 14 and the gas metering pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com