Elbow false twister

A false twister and bender technology, applied in the field of chemical fiber spinning, achieves the effects of strong universality, reduced yarn damage and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present utility model is described in further detail below.

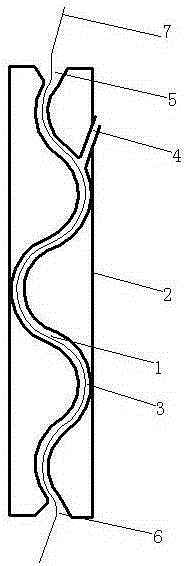

[0014] like figure 1 As shown, a pipe elbow false twister of the present invention includes a cylindrical drum 2 and an elbow 1 located inside the drum 2, and the inlet 5 and the outlet 6 provided on the elbow 1 are respectively located at both ends of the drum 2. , the elbow 1 is provided with three bends 3, and the elbow 1 is fixedly connected to the inner wall of the drum 2 at the bend 3. The cross section of the pipe 1 is circular, and the inlet 5 and the outlet 6 are trumpet-shaped openings; the wall of the elbow 1 is also provided with an air inlet 4, and the air inlet 4 cuts into the wall of the elbow obliquely or vertically, and points to the wall of the elbow. One end of the outlet of the tube 1 and one end of the air inlet 4 are located outside the drum 2 .

[0015] In one embodiment of the present utility model, a driving device of the elbow false twister...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com