Simply supported box girder with corrugated steel web and steel-concrete composite structure

A corrugated steel web and composite structure technology, used in bridges, bridge parts, bridge construction, etc., can solve problems such as inability to cooperate with force, stress concentration, stress redistribution, etc., achieve good structural performance and economy, and improve strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

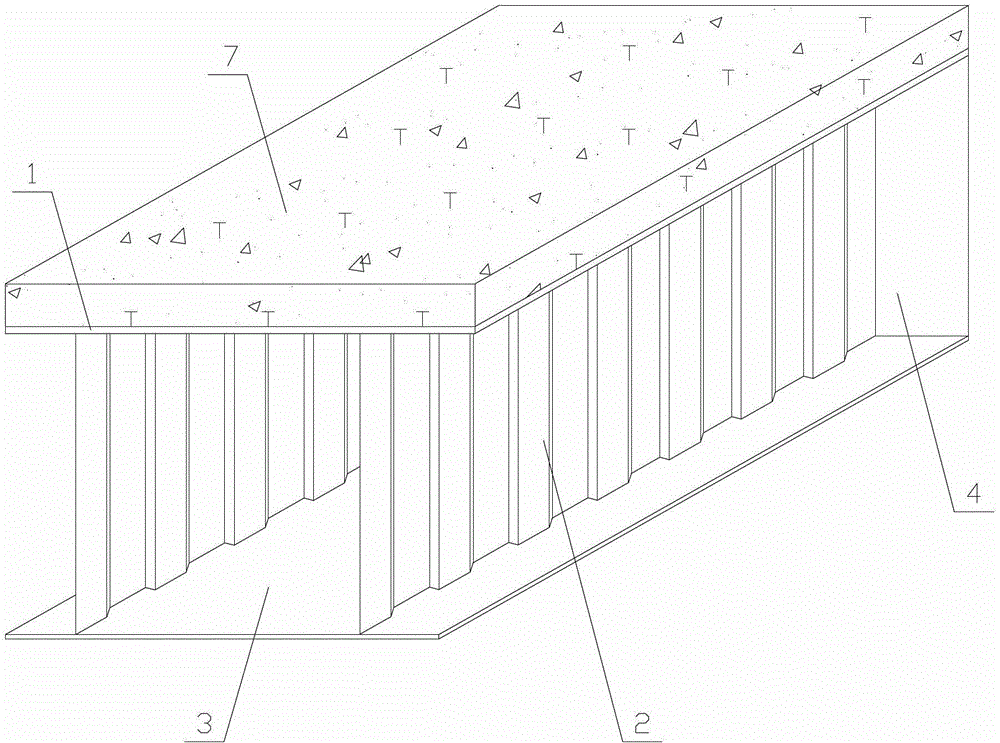

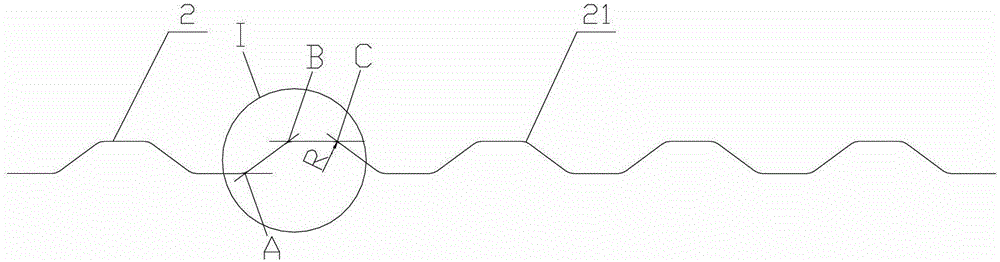

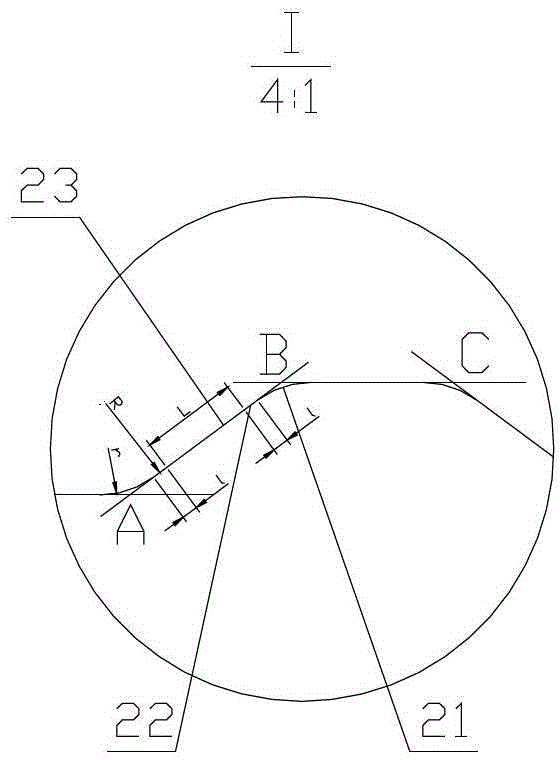

[0030] Simple supported box girder with corrugated steel web and steel-concrete composite structure, Figure 1 to Figure 7 , 8, 9 include two or more corrugated steel webs 2, top steel plate 1, concrete 7, bottom steel plate 3 and head end plate 4, characterized in that: the corrugated steel web 2 is set on the top steel plate 1 and Between the bottom steel plates 3, the top steel plate 1 and the corrugated steel web 2 are connected by welding, and the corrugated steel web 2 and the bottom steel plate 3 are connected by welding. The surface roughness of the top steel plate 1 and the bottom steel plate 3 is 70-350 μm. The top steel plate 1 or the bottom steel plate 3 and the concrete 7 are combined to form a concrete composite structure. When the simply supported box girder is an ordinary beam, the top steel plate 1 is mainly subjected to pressure. At this time, the top steel plate 1 and concrete 7 are combined to form a concrete composite structure; when the simply supported box...

Embodiment 2

[0040] Such as Figure 1 to Figure 5 , 7, 8, and 9, the difference between this embodiment and embodiment 1 is that: one end of the simply supported box beam is provided with a plug 24, and the other end is provided with a socket 25, and the plug 24 is passed between adjacent simply supported box beams. It is matched with the jack 25, the plug 24 is provided with a barb, and the jack 25 is concave. The thickness of the top steel plate 1 is smaller than the thickness of the bottom steel plate 3. At this time, the bottom steel plate 3 serves as a pressure bearing surface, and its main structure is a cantilever box beam.

[0041] The top steel plate 1 has a micro strain wave 11 with a convex wave crest. The wave height of the micro strain wave 11 is 3-20 times the thickness of the top steel plate, the peak length of the convex part is 250mm, and the distance between the wave crest and the wave crest is 1500mm. In this embodiment, the wave height of the micro strain wave is 10 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com