Auxiliary support frame for installation of wind power generation equipment in the factory area

A technology for wind power generation equipment and installation assistance, which is applied in the directions of lifting equipment safety devices, lifting devices, etc., can solve the problems of workers falling and falling, workers climbing and falling off, and workers being physically exhausted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

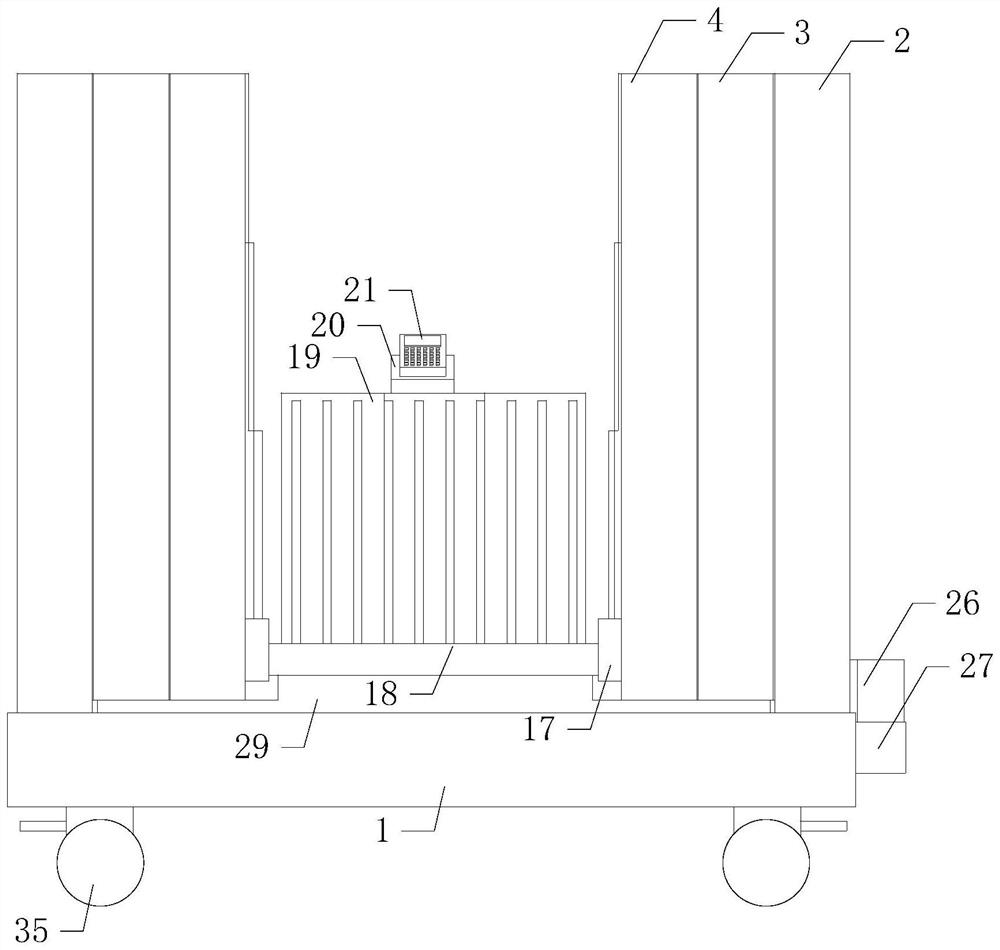

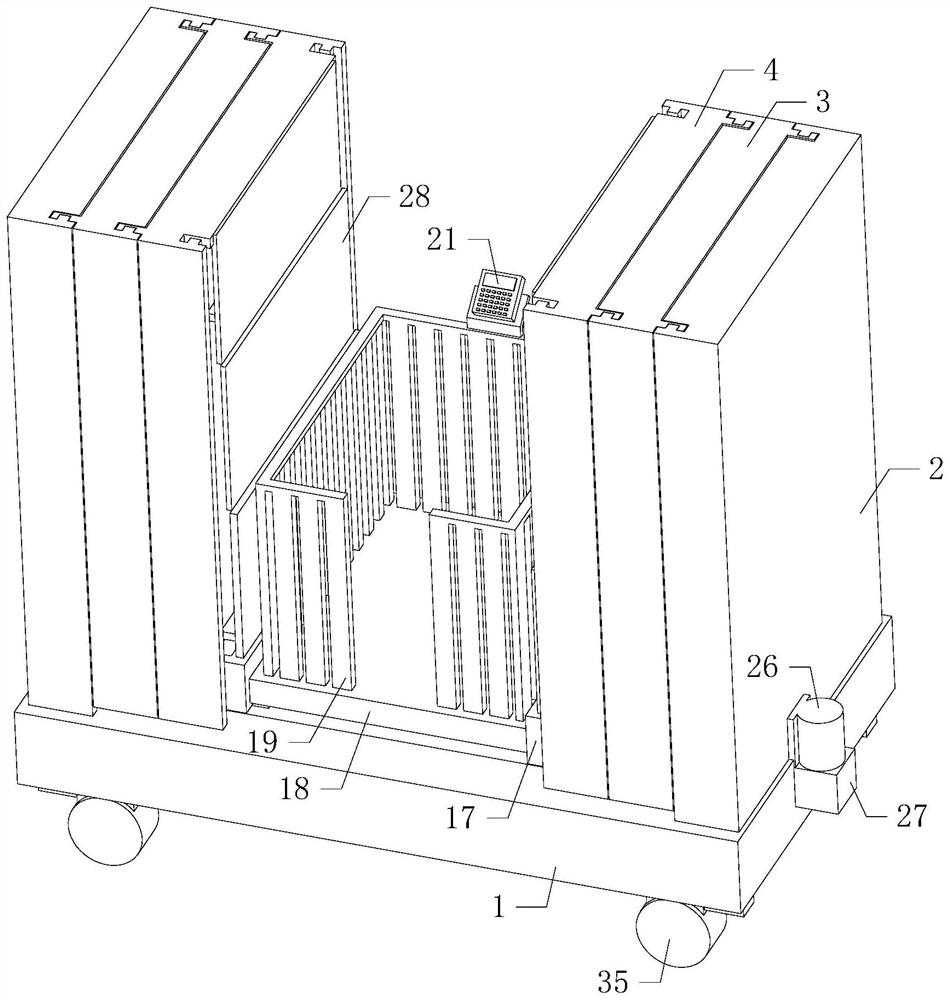

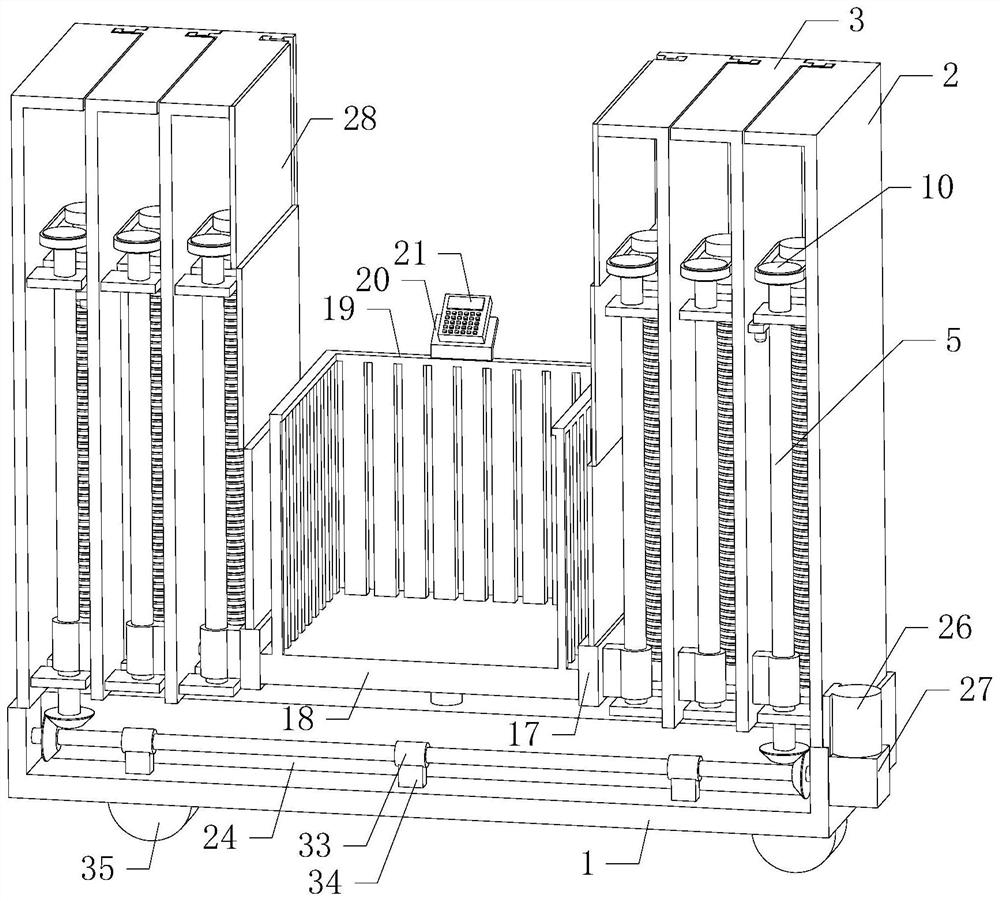

[0022] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

[0023] like Figure 1 to Figure 8 As shown in the present invention, the auxiliary support frame for the installation of wind power generation equipment in the factory area, when it is working, the working mode of the lifting mechanism is that the central control box 21 controls the opening of the power device, and the power device drives the lead screw in the first groove plate 2 5 rotate, the lead screw 5 in the first slot plate 2 drives the screw sleeve 7 on it to move up and down, and the screw sleeve 7 in the first slot plate 2 drives the second slot plate 3 to move up and down, so that the second slot plate 3 is moved up and down. 3. Sliding on the first groove plate 2, while the lead sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com