Cargo carrying table

A cargo platform and side arm technology, applied in the field of cargo platforms, can solve problems such as high precision requirements for pre-installation and debugging of equipment, delay in starting the anti-fall mechanism, unbalanced force on the lever, etc., to achieve rapid linkage anti-fall The effect of starting effect, improving immediacy and accuracy, and reducing the requirement of installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

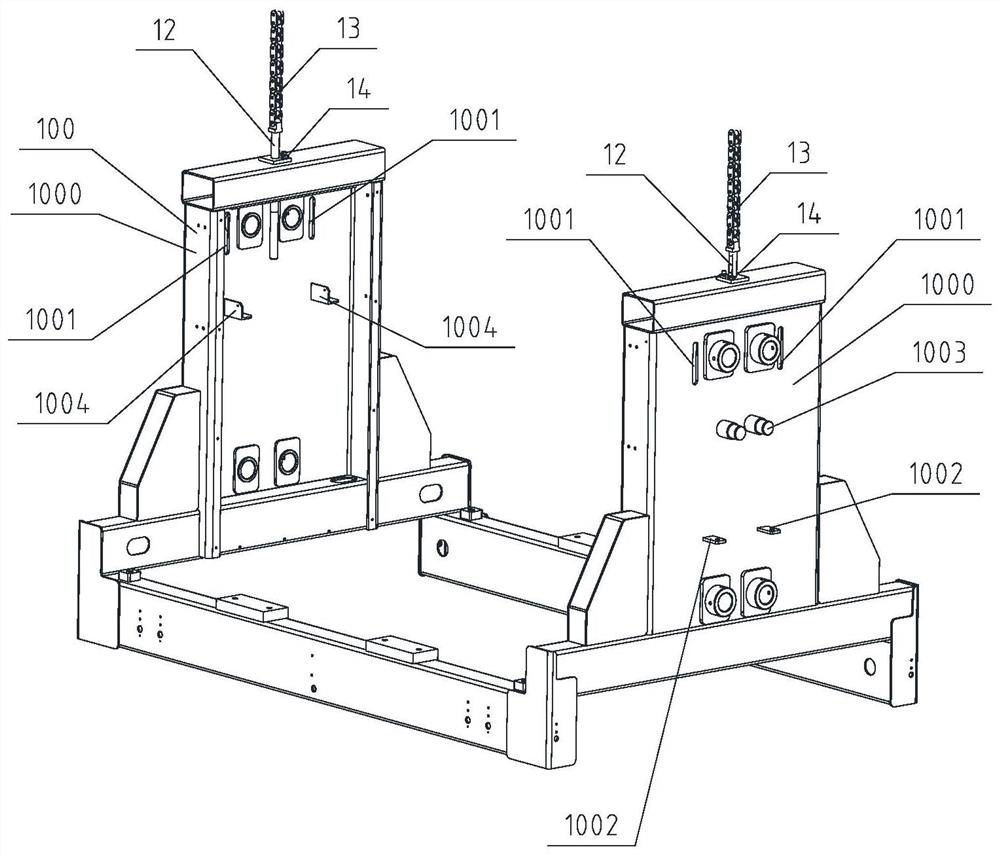

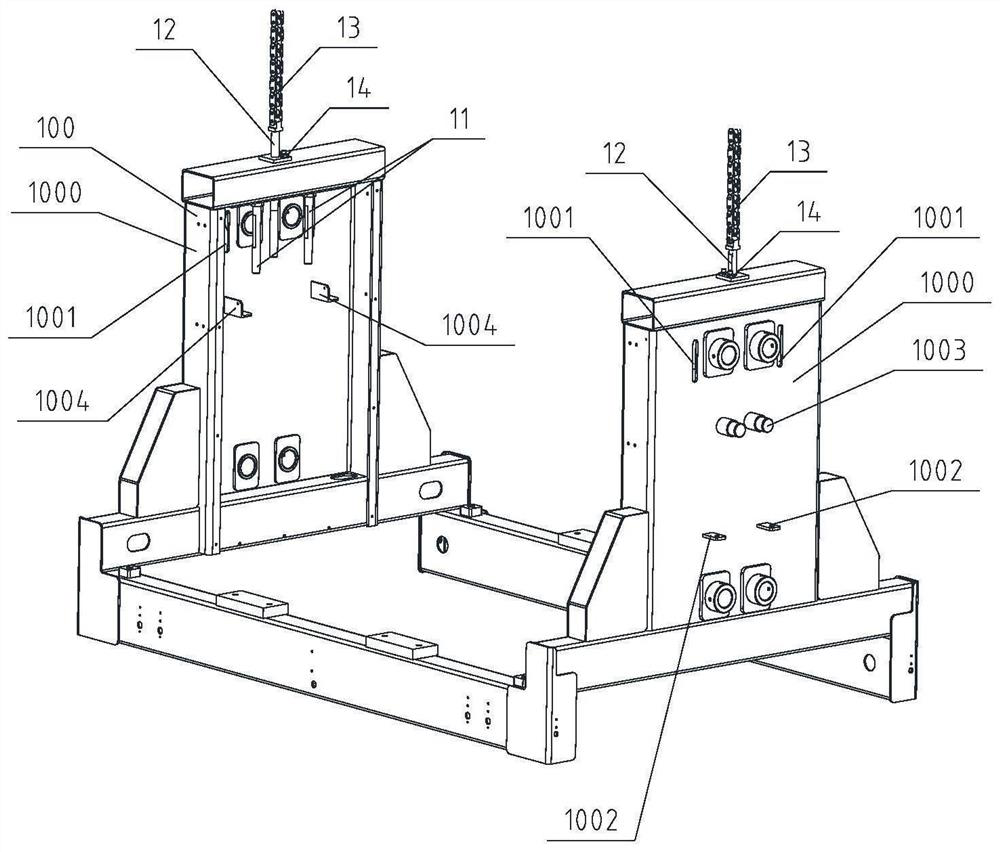

[0030] Example 1, such as Figure 1-7 As shown, the cargo platform described in the present application has two sets of cargo platform side arms 1000 connected to the lifting chains 13, and a set of cam type anti-drop mechanisms are respectively installed on each group of cargo platform side arms 1000.

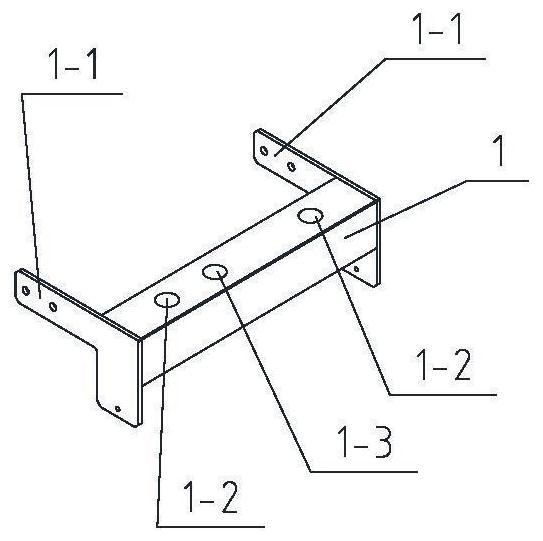

[0031] Specifically, two sets of oblong through slots 1001 , two sets of bottom positioning plates 1002 , two sets of mandrels 1003 , and two sets of upper positioning seats 1004 are installed on the cargo bed side arm 1000 . The positioning plate 1002 and the mandrel 1003 are located on the outside of the cargo platform side arm 1000 , and the upper end positioning seat 1004 is located on the inside of the cargo platform side arm 1000 .

[0032] The cam-type anti-falling mechanism includes a lifting screw 12 connected to a lifting chain 13, the lifting screw 12 runs through the top of the cargo platform side arm 1000, the upper end of the lifting screw 12 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com