Method for building dock by lifting precast panels with simple portal crane

A gantry crane and panel technology, which is applied in the field of port engineering, can solve the problems of high equipment safety risk, long construction period, and inability to move and lift construction, so as to improve construction efficiency and construction safety, reduce installation and construction costs, and shorten the The effect of installation progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

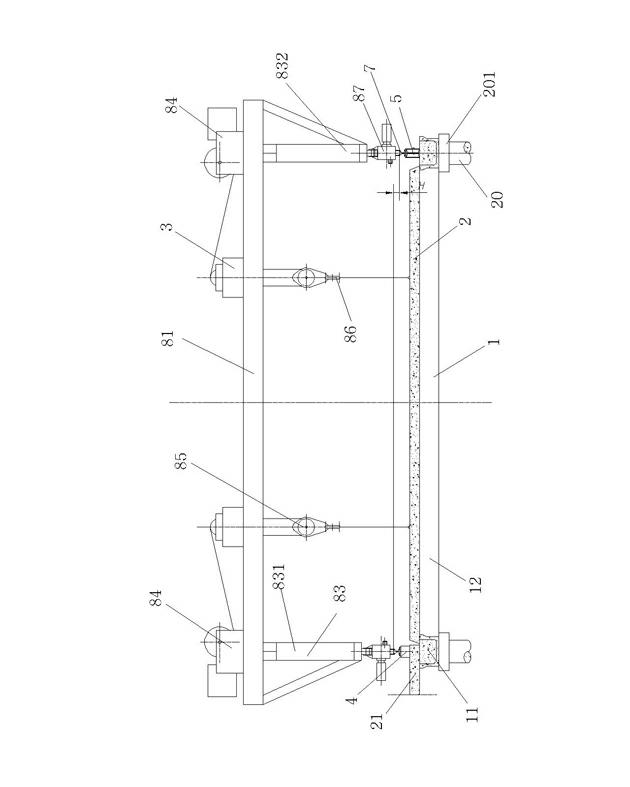

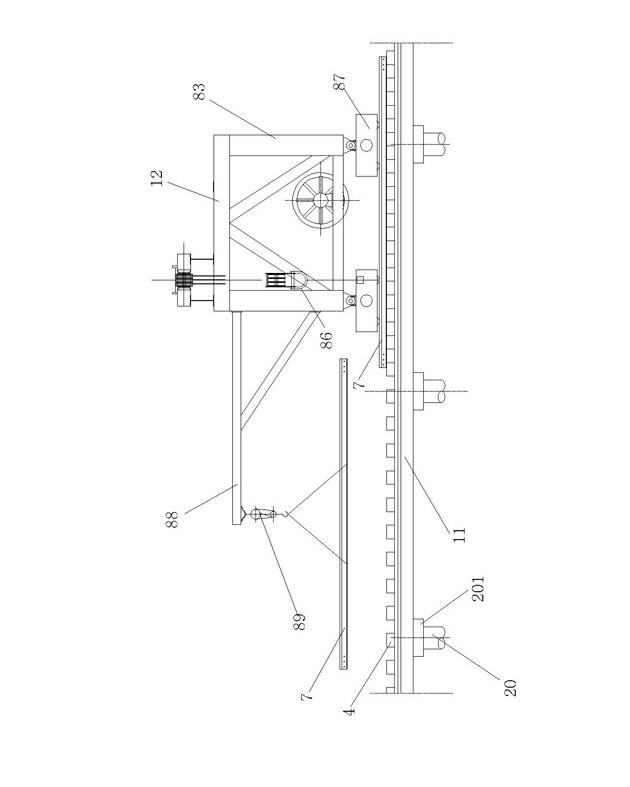

[0024] Taking the present invention as an example for building a 600m×60m ultra-wide large-scale wharf platform and approach bridge as an example, the present invention will be further described in conjunction with the accompanying drawings and embodiments.

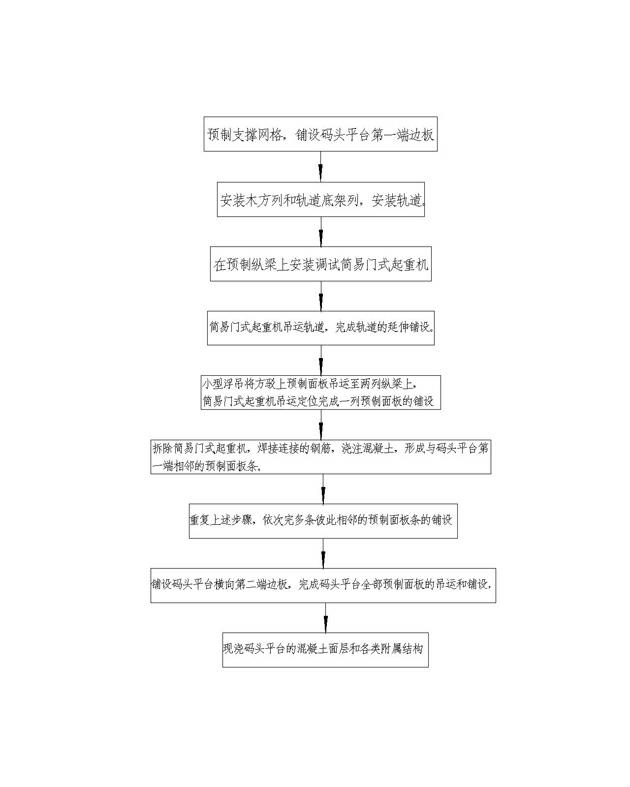

[0025] Such as Figure 1 ~ Figure 4 As shown, this embodiment includes the following steps:

[0026] 1) After the prefabricated concrete pile caps 201 have been completed on the tops of multiple engineering piles 20, multiple columns of longitudinal beams 11 and multiple rows of crossbeams 12 are prefabricated on the concrete pile caps 201 to form a wharf panel support grid 1, which includes The multi-column longitudinal beams and multi-row crossbeams of the approach bridge; the prefabricated panels 2 on the square barge 6 are hoisted and transported sequentially with a small floating crane 9, and spread on the two parallel columns of longitudinal beams at the first horizontal end 13 of the wharf platform, and the prefabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com