Half-rib laminated floor slab with floor heating pipe groove

A technology of laminated floors and floor heating, applied in floors, building components, buildings, etc., can solve the problems of large amount of manual wet work, high consumables, self-heavy and other problems, and achieve the effect of scientific and reasonable structural stress allocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the present invention is described in further detail:

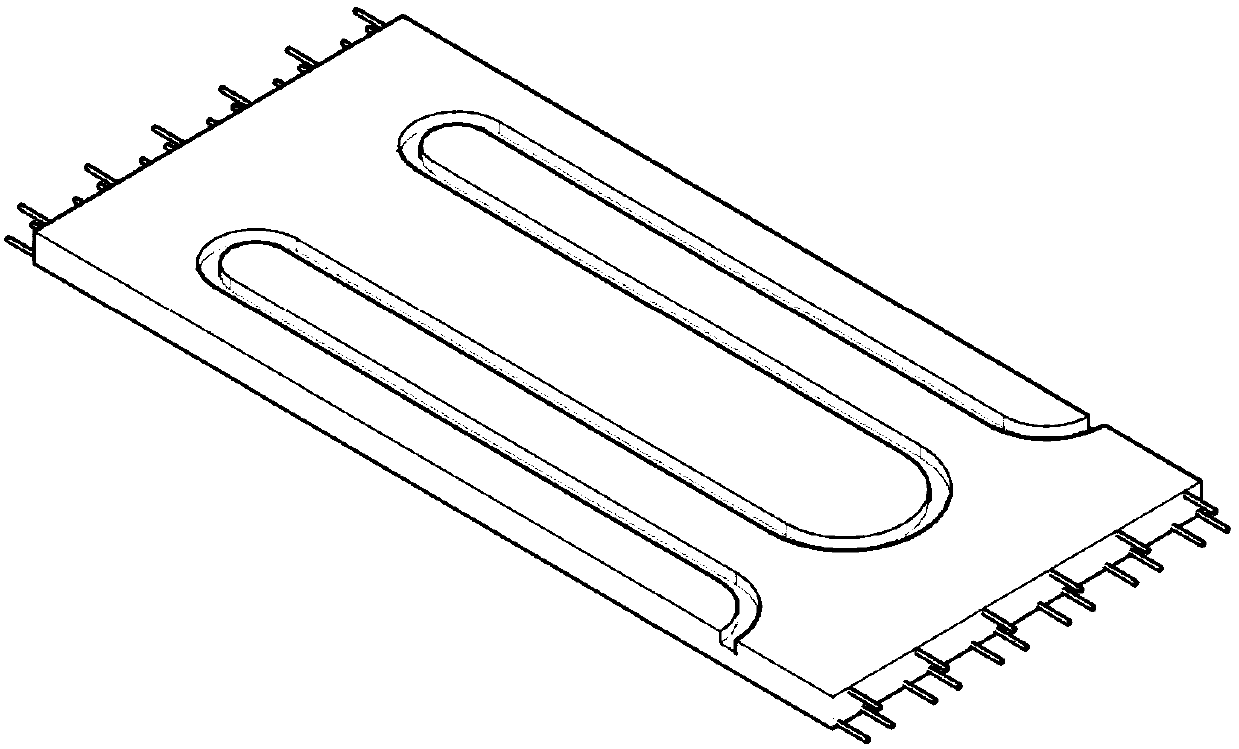

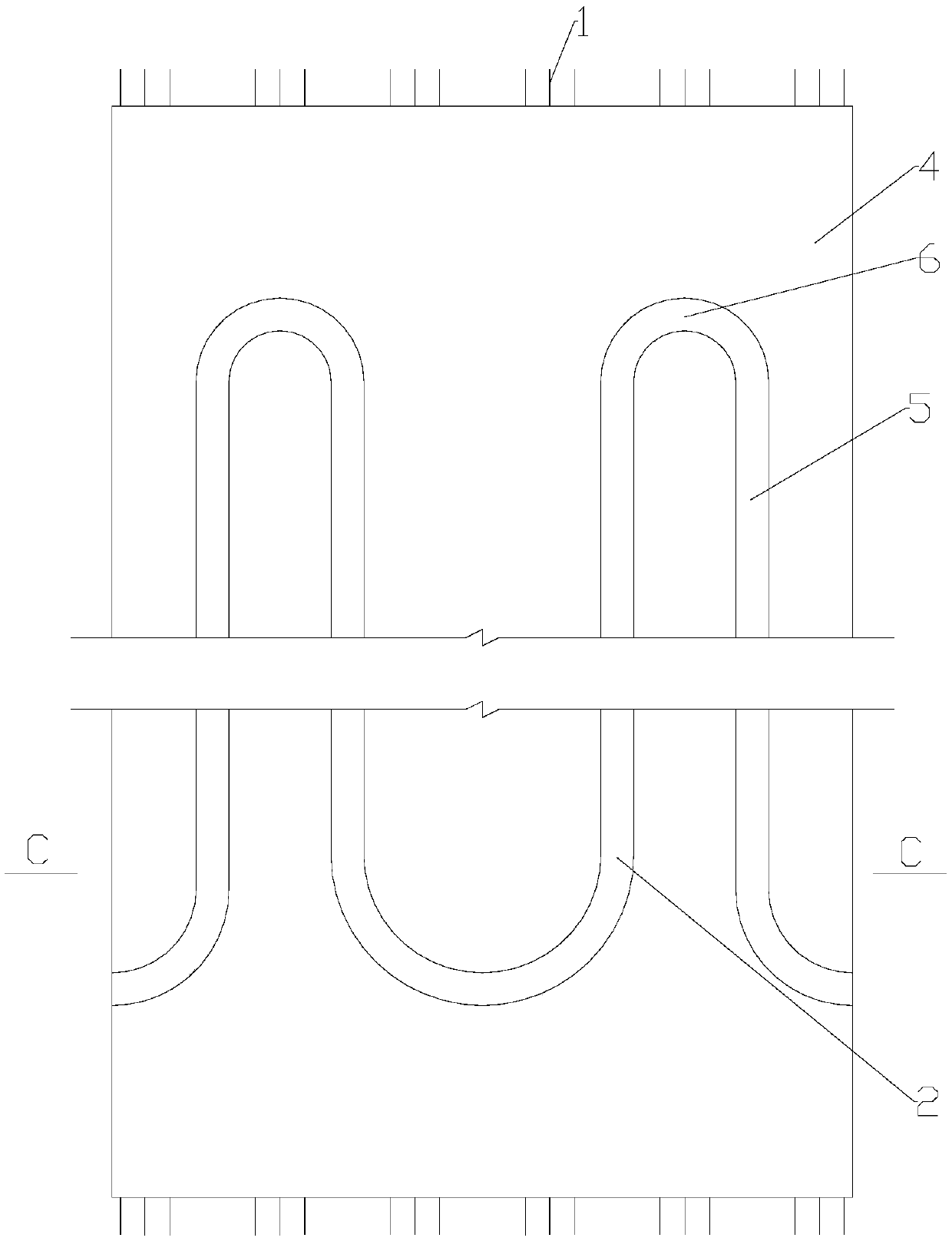

[0036] A half-rib laminated floor with floor heating pipe grooves, the laminated floor has an open floor heating pipe groove 2, and the floor heating pipe groove 2 is recessed into the laminated floor without increasing the structural layer thickness of the original laminated floor The post-cast reinforced concrete structure layer 4, the upper opening of the floor heating pipe groove 2 is flush with the surface of the post-cast reinforced concrete structure layer 4 of the laminated floor slab.

[0037] Floor heating pipe groove 2 is 50mm deep and 80mm wide.

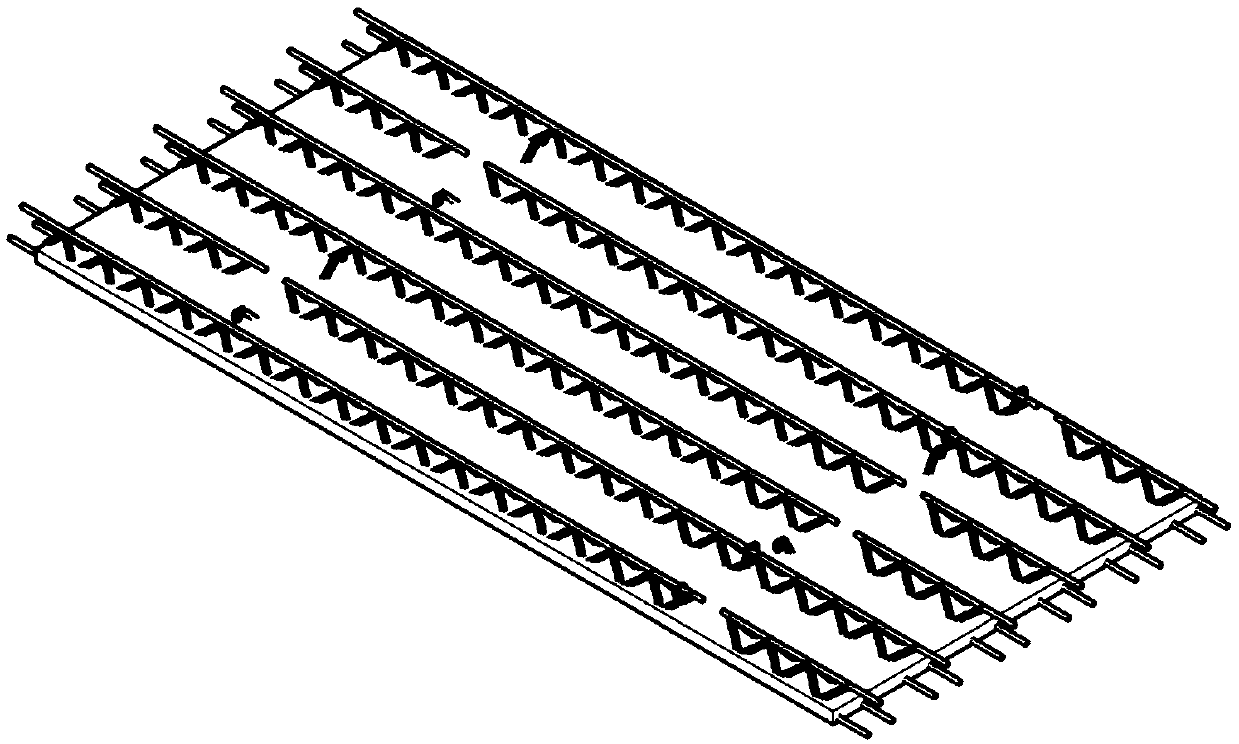

[0038] The laminated floor adopts the configuration of floor heating pipe straight groove 2 and unidirectional stress reinforced concrete floor, arranged along the direction of the span of the slab, and arranged at intervals,

[0039] The ground heating return groove 6 is arranged at the position where the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com