Hot melt adhesive used for steel reinforced spirally wound drainage pipe and preparation method of hot melt adhesive

A technology of hot-melt adhesives and drainage pipes, applied in the direction of adhesives, grafted polymer adhesives, adhesive types, etc., can solve the problem of increasing the construction and installation cost of plastic-steel winding drainage pipes, the impact of lightweight plastic-steel winding drainage pipes, and increasing Problems such as the specific gravity of hot melt adhesives, to achieve the effect of enhancing mechanical strength, small joint range, and reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-7

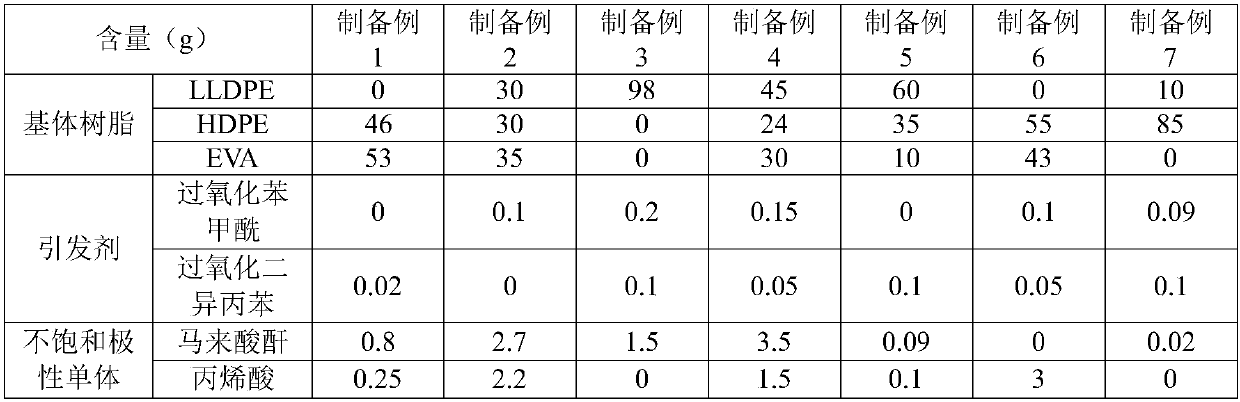

[0037] According to the weight parts in the following table 1, add initiator and unsaturated polar monomer to the base resin, at the temperature of 150°C, 155°C, 158°C, 160°C, 165°C, 170°C and 167°C The adhesive resin masterbatches of Preparation Examples 1-7 were respectively obtained by parallel twin-screw extrusion well known in the art.

[0038] Composition and content of bonding resin masterbatch in table 1 preparation example 1-7

[0039]

Embodiment 1-7

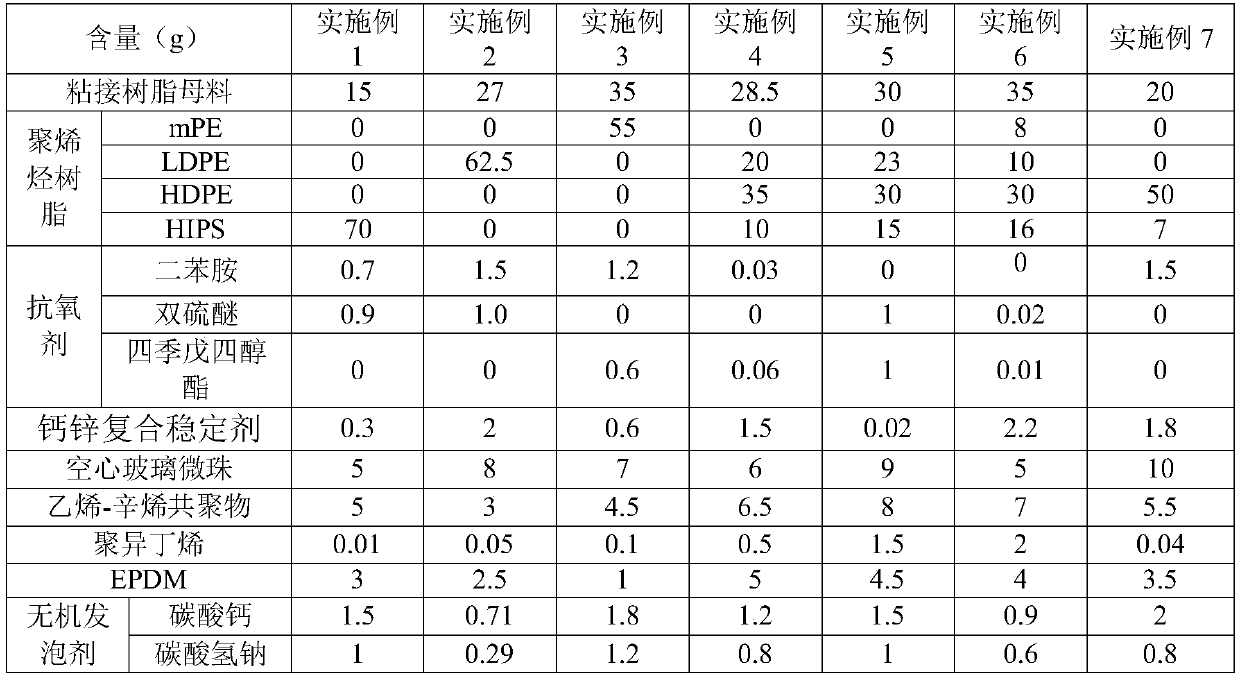

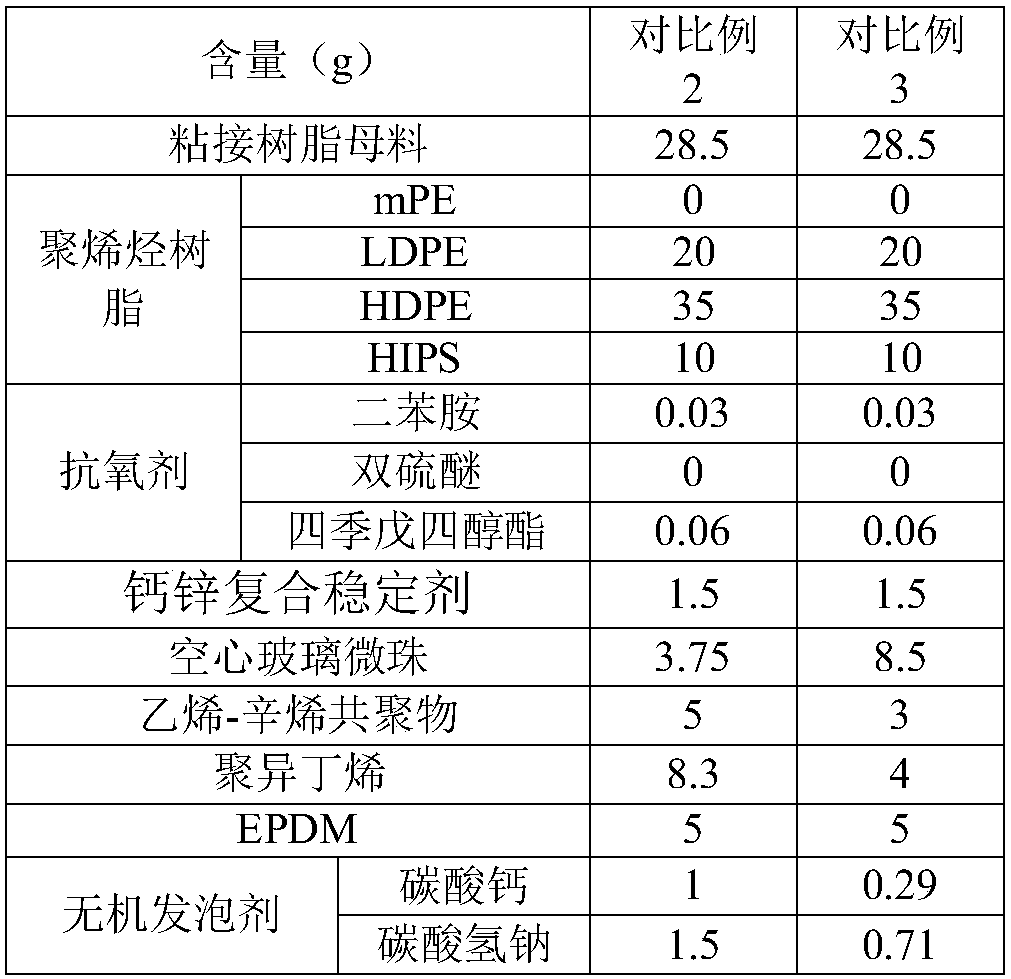

[0041] The adhesive resin masterbatches of Preparation Examples 1-7 were used as the adhesive resin masterbatches in the raw materials for preparing hot-melt adhesives in Examples 1-7 respectively, and according to the raw material content in Table 2, hot-melt adhesives were prepared through the following steps: glue:

[0042] (1) Mix and stir the adhesive resin masterbatch with polyolefin resin, ethylene-octene copolymer, EPDM rubber, polyisobutylene, antioxidant and stabilizer evenly, carry out twin-screw extrusion, and heat in the barrel The temperature is 165°C, the die temperature is 190°C, the screw speed is 40rmp, and the feeding speed is 40rmp, twin-screw extrusion to obtain high-temperature block A;

[0043] (2) Feed the high-temperature block A directly into the single-screw extruder, and at the barrel heating temperature of 160°C, the die temperature of 160°C, and the screw speed of 40rmp, add an inorganic foaming agent at the feeding port, Add hollow glass microsp...

Embodiment 8

[0048] The composition and content of each raw material of embodiment 8 and embodiment 4 are all the same, and the difference is that in step (1), at barrel heating temperature 150°C, die temperature 150°C, screw speed 50rmp, feed speed 50rmp, twin-screw Extrude to obtain high-temperature block A; in step (3), pelletize the obtained pellets and pass through an 80-mesh sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com