Method for applying flexible connector to leakage repair and butt joint of prestressed cement pipe

A flexible interface and application method technology, applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc., can solve the problems of long water stop time, shortened water stop time, and many interfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

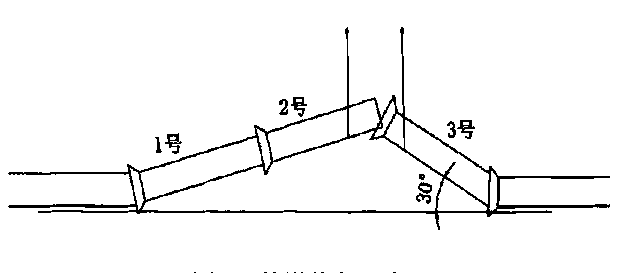

[0011] Below in conjunction with accompanying drawing, the present invention is further described, and present way is to adopt the construction of changing pipe method, and in fact this way is effective, and concrete way is as follows:

[0012] (1) Preparations before construction and restoration: 1 excavator, 2 cranes, 1 pumping equipment, 1 replacement cement pipe, 2 rubber rings, plus some small supporting tools.

[0013] (2) In order to clearly explain the situation, we code the replaced cement pipe as No. 2 (replacing the damaged water pipe), and the cement pipe with the socket facing the No. 2 pipe is coded as No. 1, and the socket is facing the No. 2 pipe. The cement pipe is coded as No. 3.

[0014] (3) The excavator digs out the covering soil of No. 1~3 pipes, and manually cleans the remaining soil in the pipe ditch.

[0015] (4) Lift the damaged cement pipe in the middle by the crane, align the socket of No. 2 pipe with the socket of No. 1 pipe (the socket of No. 1 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com