Current aging technical device for vacuum arc-extinguishing chamber

A technology of vacuum interrupter and process device, which is applied in the direction of high voltage/high current switch, circuit, electric switch, etc. It can solve the problems that the arc duration cannot be accurately guaranteed, and the current aging process cannot be achieved, and the automatic control of the duration can be achieved. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

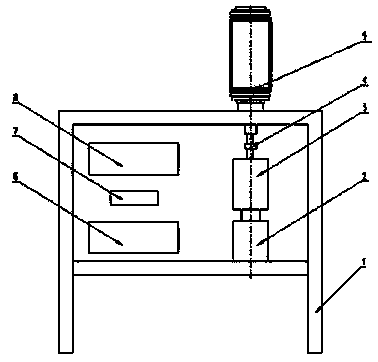

[0012] Such as figure 1 As shown, put the vacuum interrupter (5) on the upper installation position of the frame (1), connect it with the pneumatic reversing valve (3) through the connecting screw (4), and the opening and closing speed adjustment mechanism (2) adjusts the pneumatic The air pressure of the reversing valve controls the opening and closing speed of the vacuum interrupter (5) and the duration of the arc. The automatic control system (8) controls the start-up of the DC current source (6), and the automatic control system (8) controls the pneumatic reversing valve (3 ) drives the connecting screw (4) and the vacuum interrupter (5) to complete the opening and closing action, and the automatic control system (8) controls the power polarity changeover switch (3) to complete the current aging process requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com