Anti-friction bearing, in particular two-row anti-friction bearing, having a power generation unit, in particular for mounting a roller

A technology for rolling bearings and generating units, applied in rolling contact bearings, roller bearings, bearings in rotating motion, etc., can solve problems such as structural space not being optimally utilized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

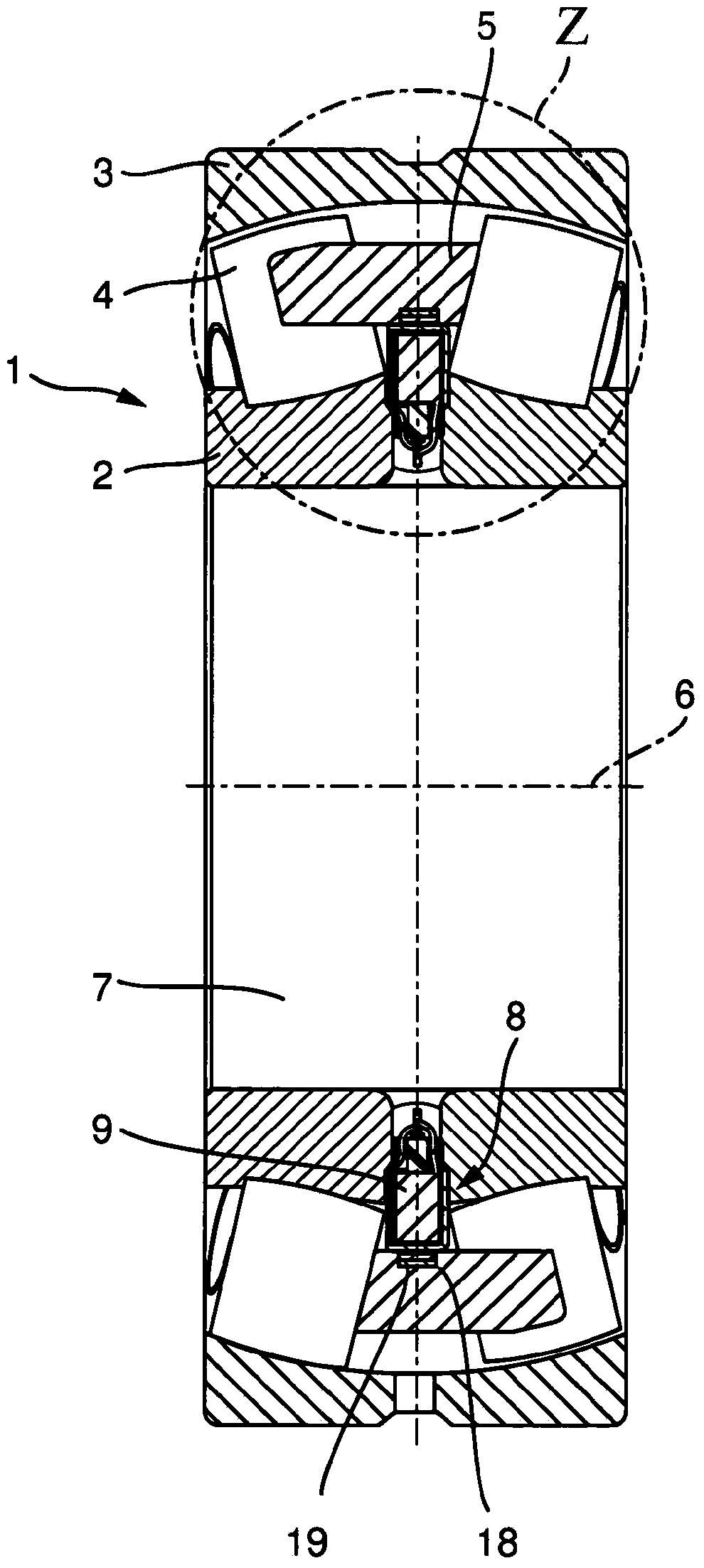

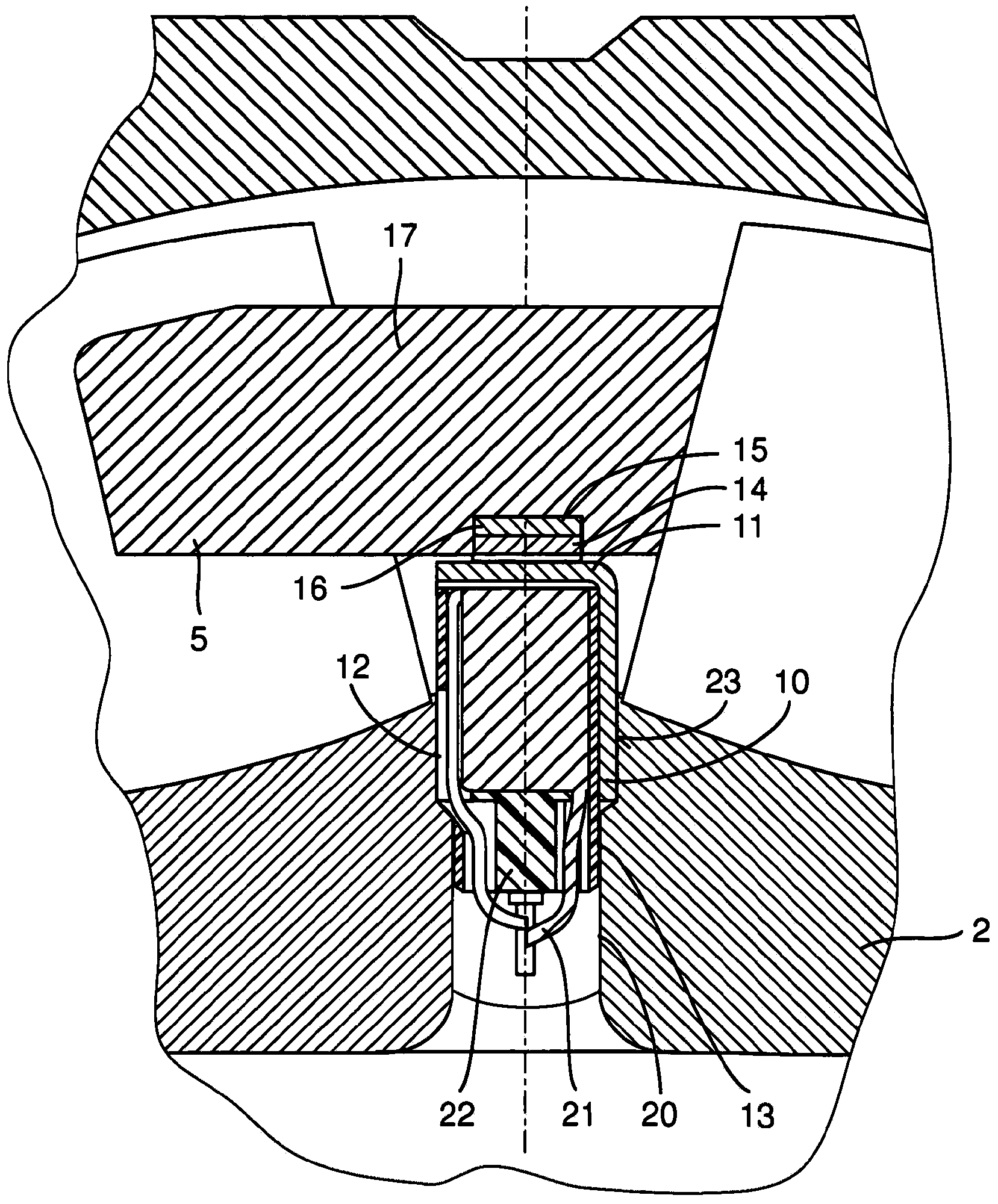

[0022] figure 1 A rolling bearing 1 is shown which comprises a first bearing ring 2 and a second bearing ring 3 . The rolling bearing 1 is designed as a double row and includes two rows of rolling bodies 4 which are designed as spherical rollers. The rolling elements 4 are guided by the bearing cage 5 with respect to the axis of rotation 6 of the rolling bearing 1 in the circumferential direction and axially, that is to say essentially parallel to the axis of rotation 6 of the rolling bearing 1 , and are kept spaced apart. The two rows of spherical rollers are arranged staggered upwards from each other.

[0023] Roller bearing 1 is part of a bearing arrangement for rotatably supporting a roll, ie a guide roll for a paper web of a printing press, wherein a conically changing shaft 7 is held rotatably about an axis of rotation 6 .

[0024] The guide roller has pressure sensors which detect the pressing force of the paper web on the outer peripheral side of the roller, wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com