Cutting tools

A technology of cutting tools and cutting knives, which is applied in the direction of manufacturing tools, metal sawing equipment, metal processing equipment, etc., can solve the problem of dust flying, and achieve the effect of preventing dust flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

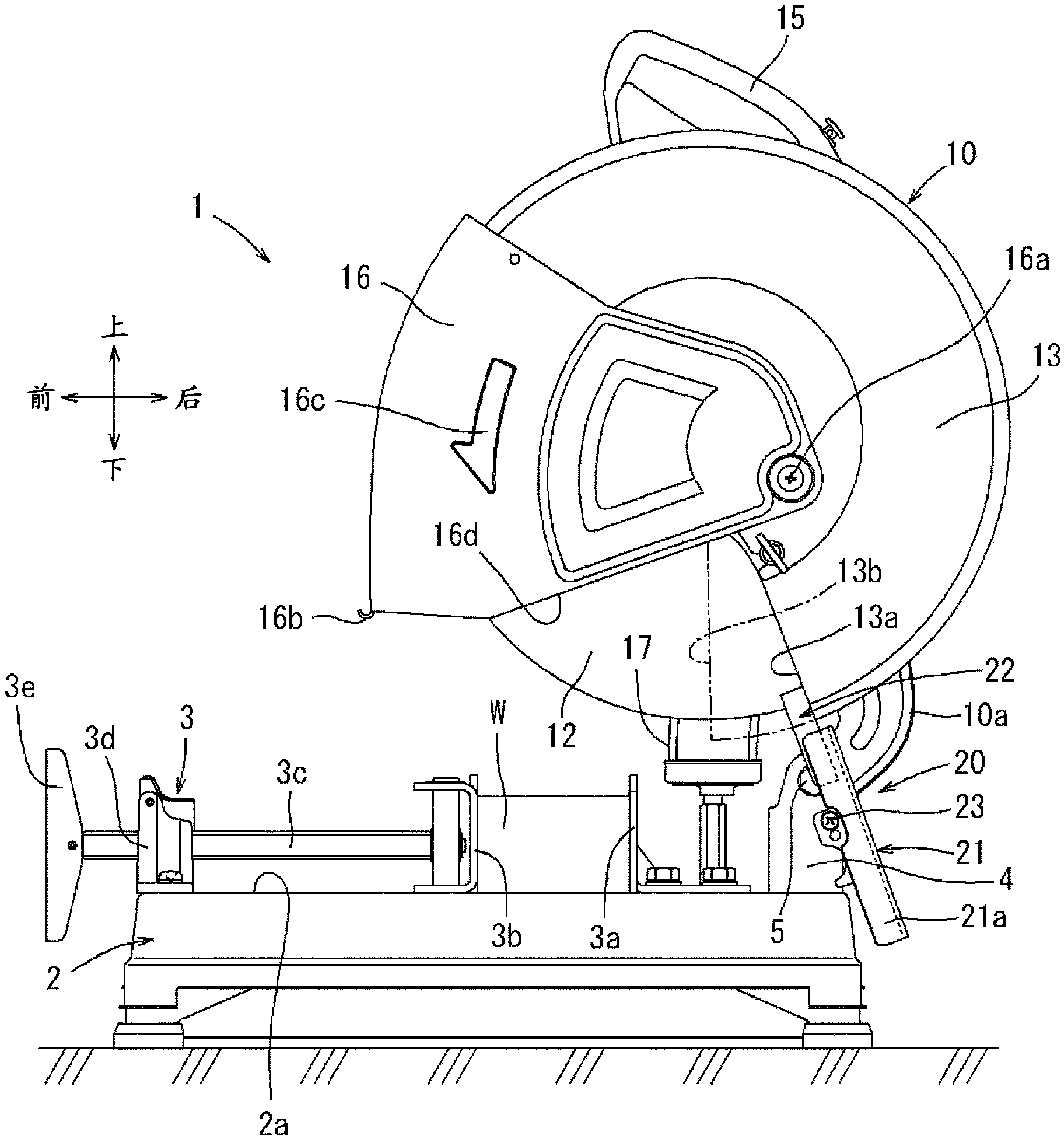

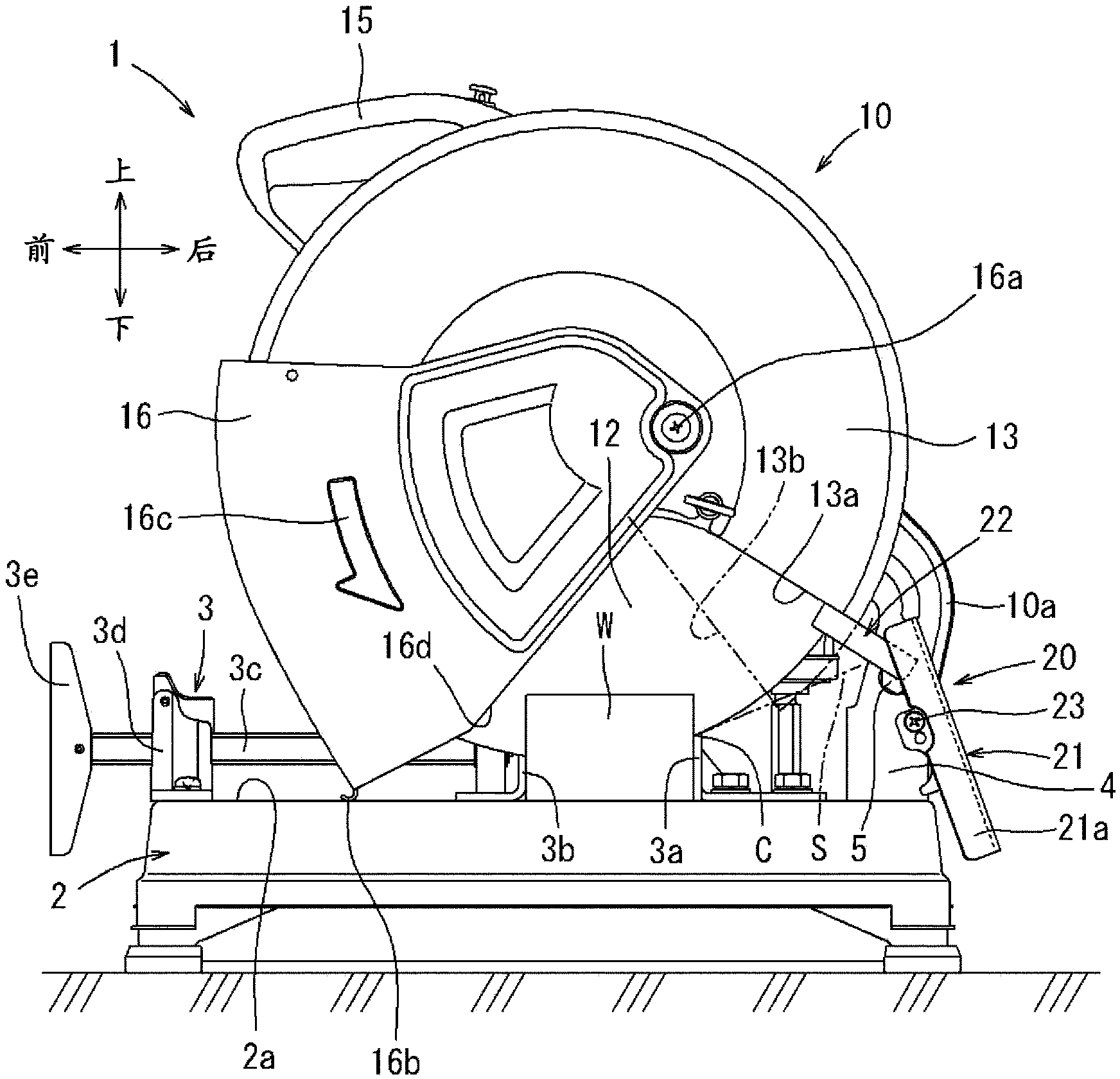

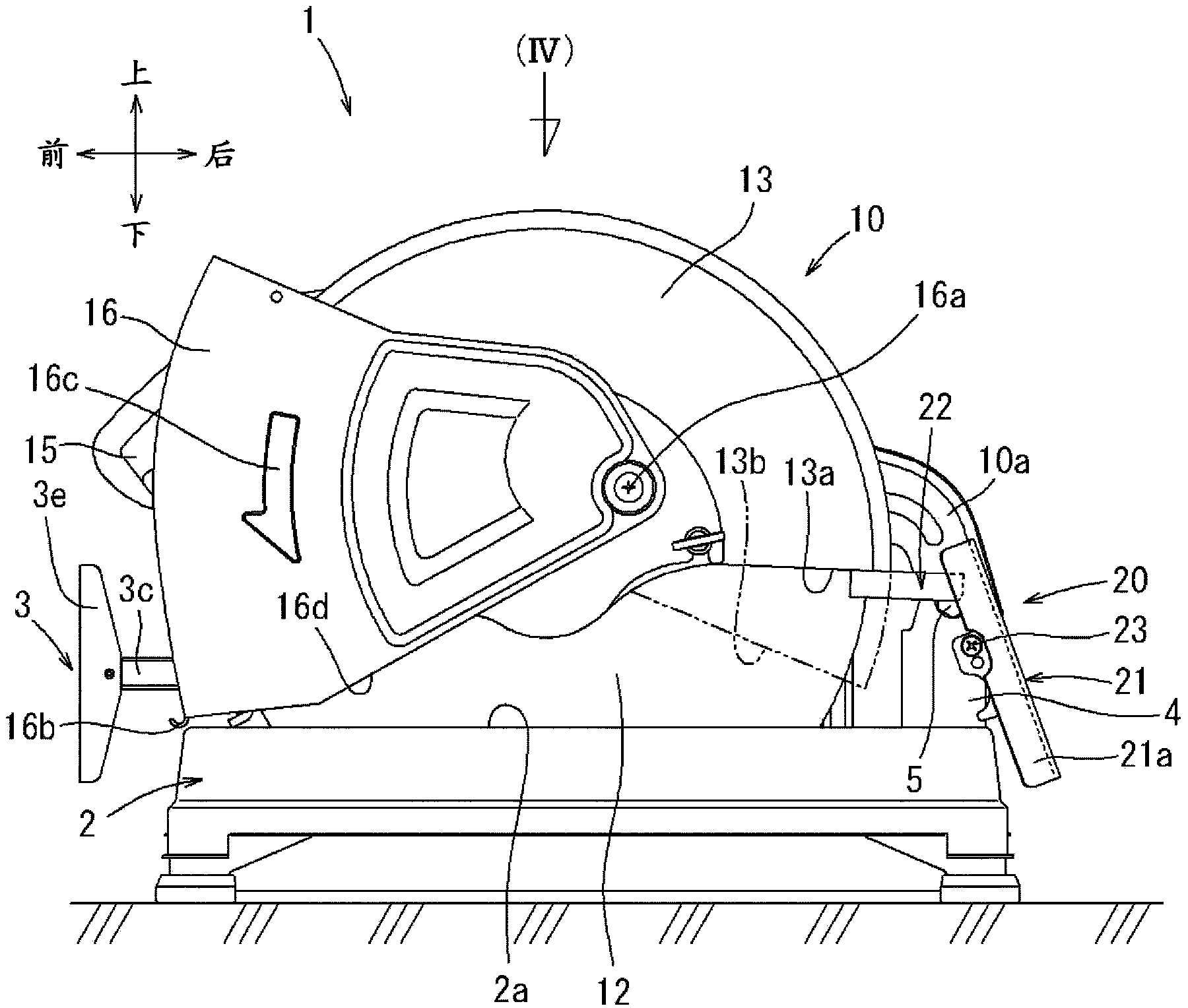

[0033] Refer below Figure 1 to Figure 8 Specific embodiments of the present invention will be described. figure 1 Shown is the cutting tool 1 according to this embodiment. The cutting tool 1 is a cutting machine for metal processing mainly used for cutting a workpiece W such as a metal material, and has a base 2 and a tool body 10, wherein the base 2 is used to place the workpiece W On; the tool body 10 is supported on the base 2 . exist figure 1 In , the operator operates the cutting tool 1 on the left side of the drawing. In the following description, regarding the front-rear direction of components and the like, the front side as seen from the operator (left side in the drawing) is defined as the front side, and the side away from the operator (right side in the drawing) is defined as the rear side. Additionally, if Figure 4 As shown, the left and right directions are directions based on the operator.

[0034]A clamp device 3 for fixing the workpiece W to be cut is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com