Superfinishing method for outer circle of high-precision cylindrical part

A technology of ultra-finishing and processing methods, applied in metal processing equipment, work carriers, manufacturing tools, etc., can solve the problems of poor processing consistency and poor uniformity, and achieve the effect of low manufacturing cost, less surface damage and residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings.

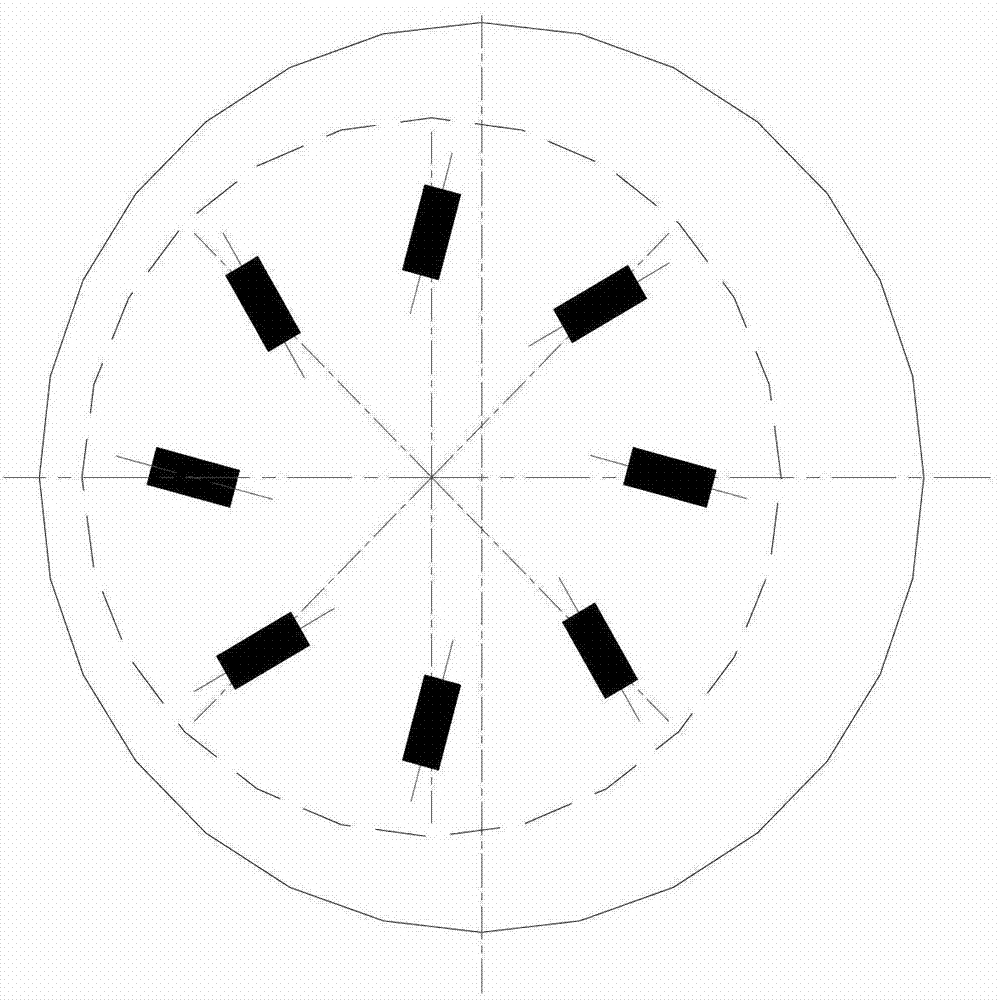

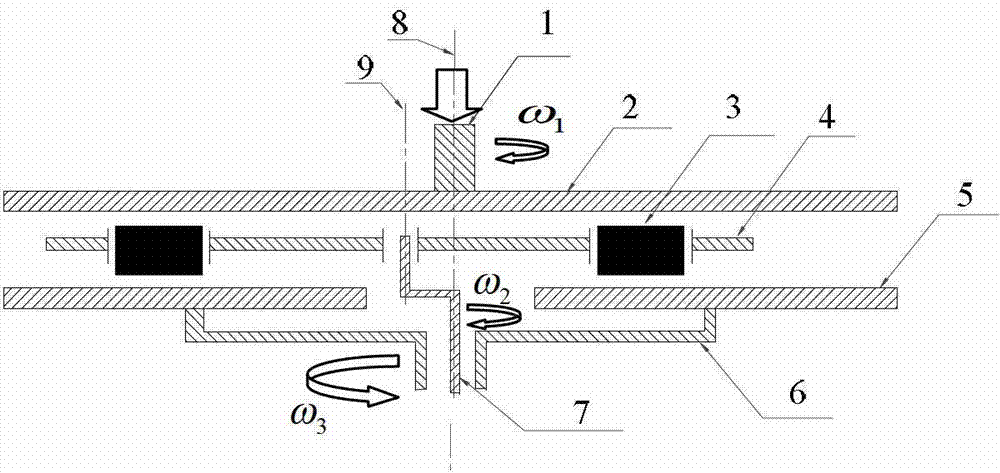

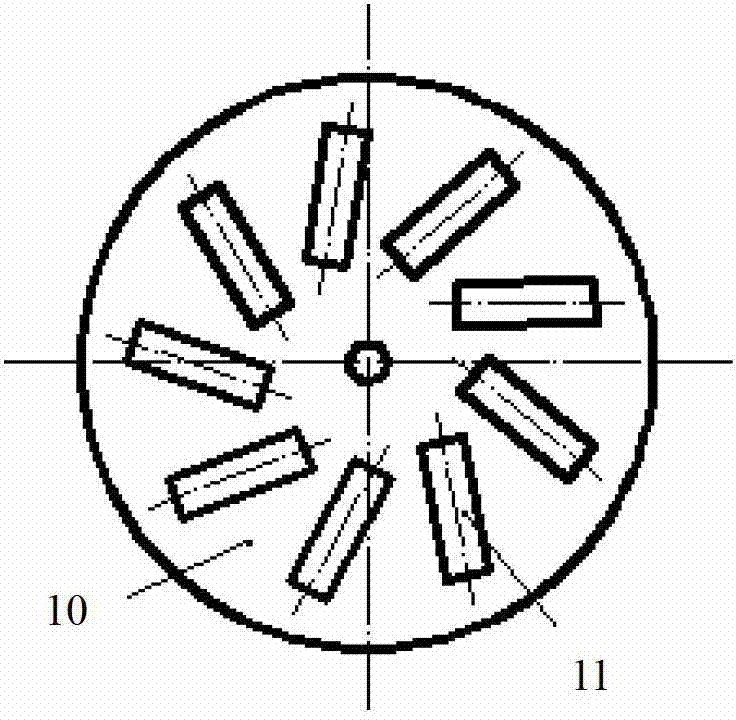

[0020] Reference Figure 1 ~ Figure 4 , A method for superfinishing the outer circle of a high-precision cylindrical part, and a processing device for realizing the processing method, comprising an upper grinding disc 2, a holder 4 and a lower grinding disc 5, the upper grinding disc 2 is located on the lower grinding disc Above 5, the holder 4 is located between the upper grinding disc 2 and the lower grinding disc 5. The rotation axis of the upper grinding disc 2 and the rotation axis of the lower grinding disc 5 are arranged coaxially. , The rotating shaft of the lower grinding disc has a definite offset, the cage 4 is connected with the cage driving crankshaft 7, and the upper grinding disc, the lower grinding disc, the cage, and the cage driving crankshaft can rotate independently at their respective speeds;

[0021] The processing method includes the following processes: the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com