a conversion mechanism

A conversion mechanism and gear technology, which is applied in the direction of mechanical equipment, transmission parts, gear transmissions, etc., can solve the problems of reducing the service life of micro switches, etc., and achieve the effect of simplifying the meshing action process, improving the service life and rapid conversion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

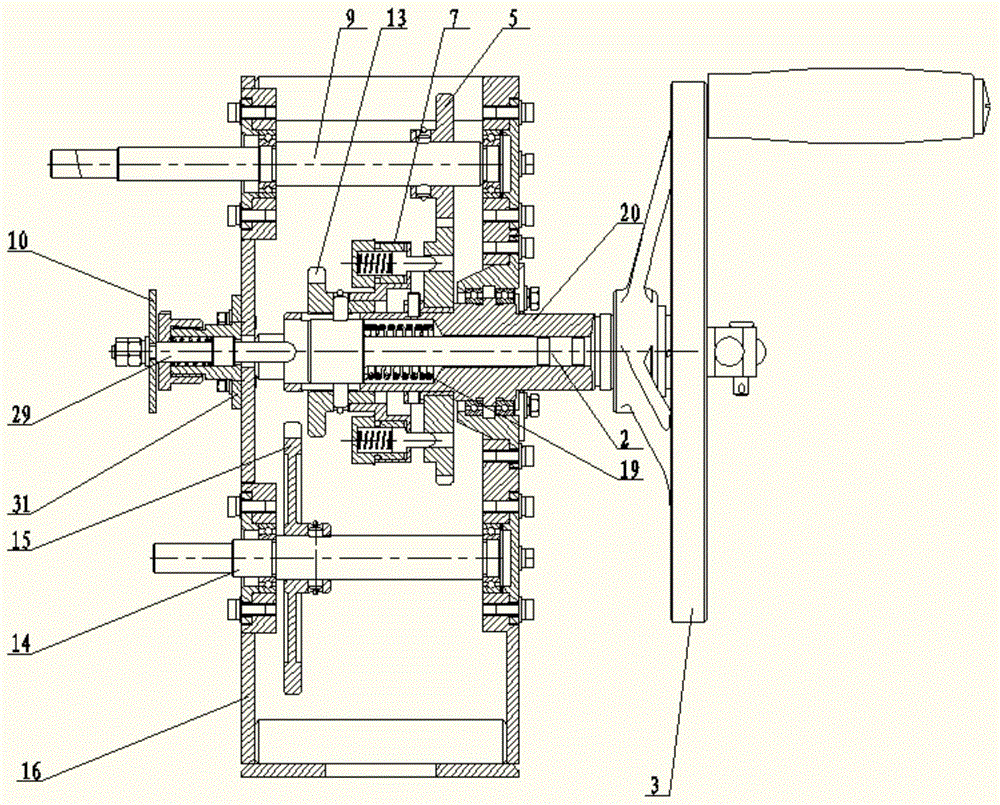

[0026] This embodiment provides an electric / manual switching mechanism used on the launcher, by controlling the meshing of the input gear and the output gear and the automatic insertion of the pin into the waist-shaped groove of the transition gear, the switching between the manual direction of the launcher and the high-low manual is realized. ; And the contacts of the micro switch are not in contact with the rotating parts, which improves the service life of the switch.

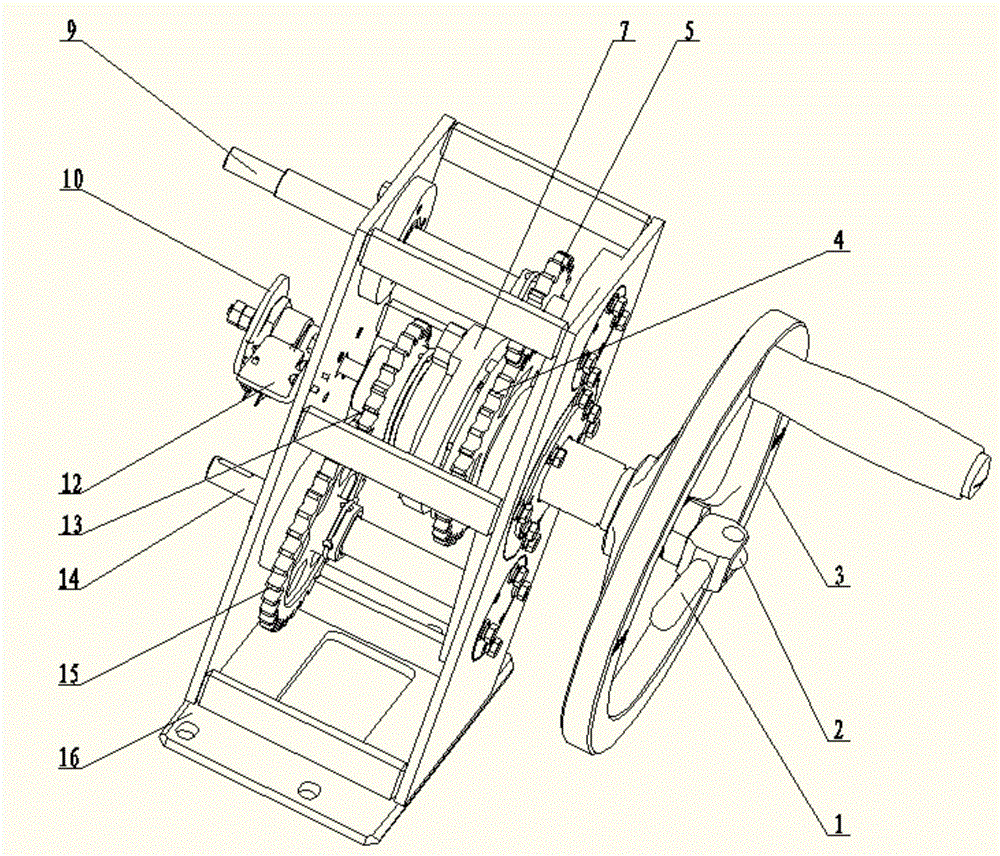

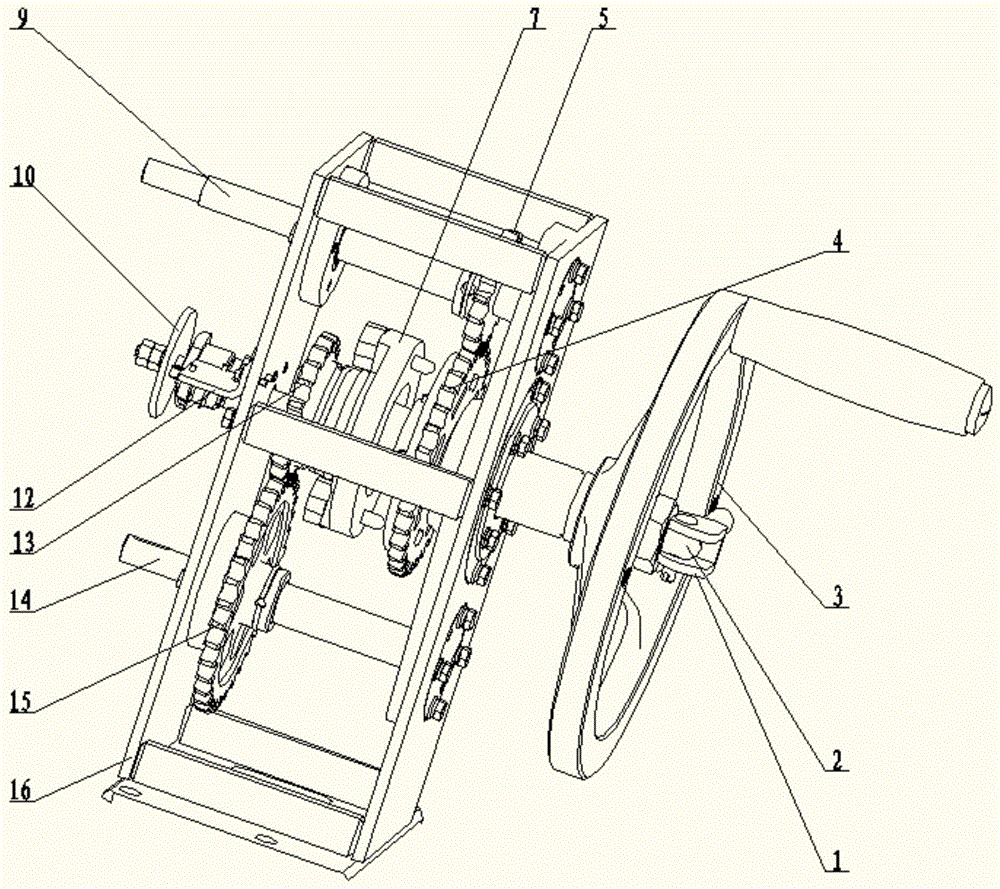

[0027] The conversion mechanism includes conversion handle 1, pull rod 2, hand wheel 3, transition gear 4, gear A5, chassis 7, output shaft A9, pressure plate 10, switch mounting frame 12, gear B13, output shaft B14, gear C15, box 16, stage clip A19, axle sleeve 20, connecting shaft 29 and sleeve 31 etc.

[0028] The conversion mechanism has two meshing states: meshing stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com