Open-loop positioner and error elimination method for measurement

A technology for measuring errors and measuring points, which is applied in the field of open-loop positioning devices for measurement and error elimination, can solve the problems of poor accuracy of results, large errors, and inability to accurately return to the calibration point, etc., to achieve device and structure realization , The effect of eliminating positioning errors and mechanical errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

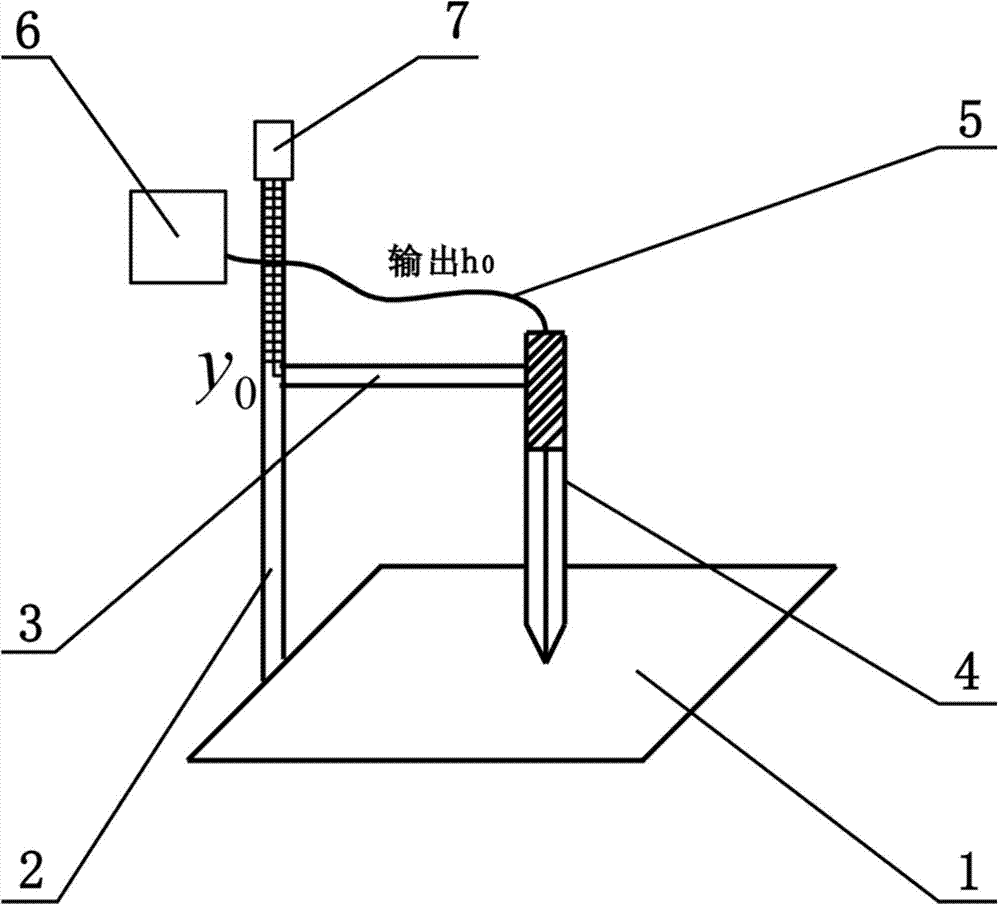

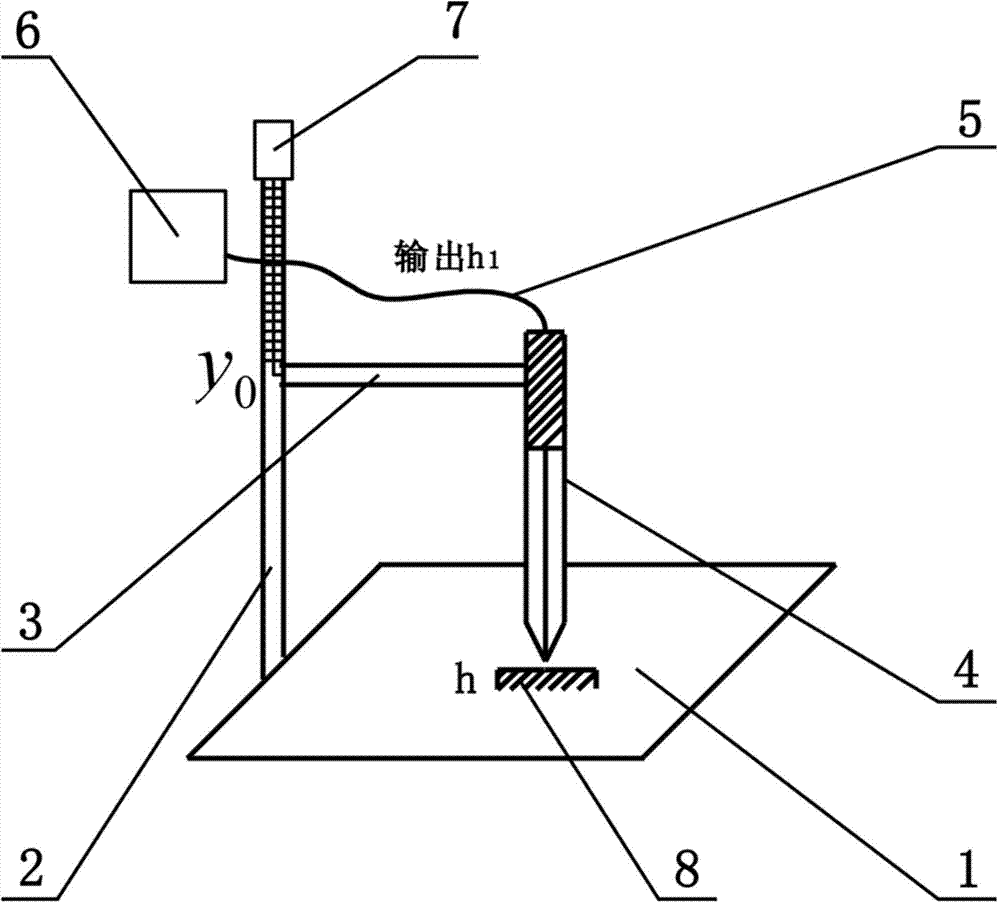

[0027] Such as Figure 1 ~ Figure 4 As shown, a kind of open-loop positioning measuring device used for measurement includes a vertical guide rod 2 and a test reference surface 1 connected with the vertical guide rod 2, and a distance measuring sensor 4 is provided on the vertical guide rod 2 for horizontal sliding connection The distance measuring sensor 4 is electrically connected to the data collector 6, and the vertical guide rod 2 is provided with a servo motor 7, and the servo motor 7 drives the distance measuring sensor 4 to slide up and down in the vertical guide rod 2.

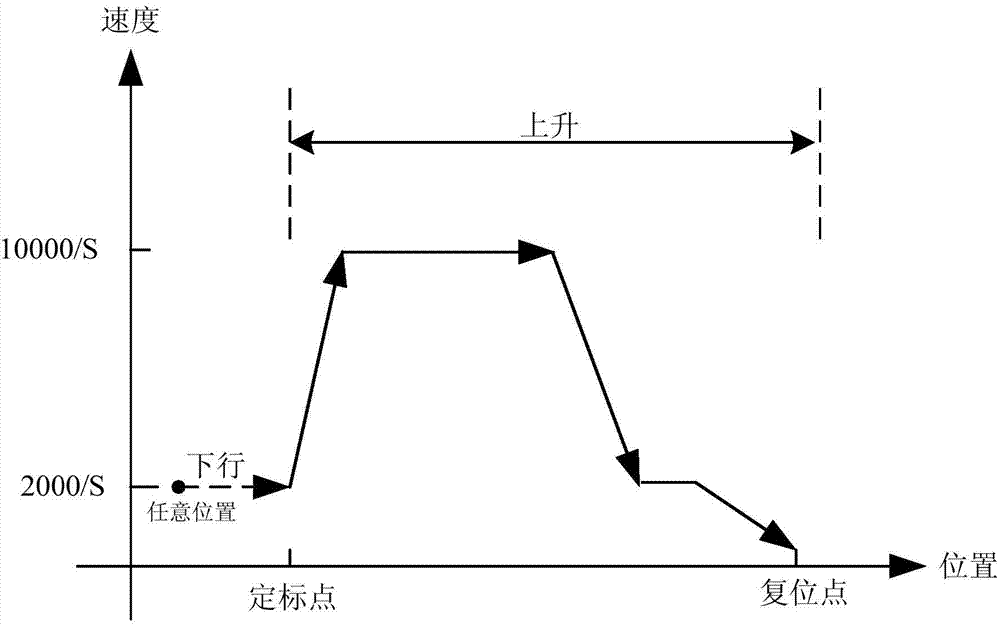

[0028] Such as figure 2 As shown, during the measurement process of the thickness measuring device, when the measured sheet is not placed, the distance measuring sensor 4 is driven by the servo motor 7 to slide down from the highest point of the measuring device, so that the distance measuring sensor 4 measures out between the marble platforms. and write down the current position y of the ranging se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com