LED chip and manufacturing method thereof

A technology for light-emitting diodes and a manufacturing method, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of reducing the service life of light-emitting diodes, uneven brightness of light output, heat accumulation at electrodes, etc., so as to improve the uniformity of current diffusion. , The brightness is uniform, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

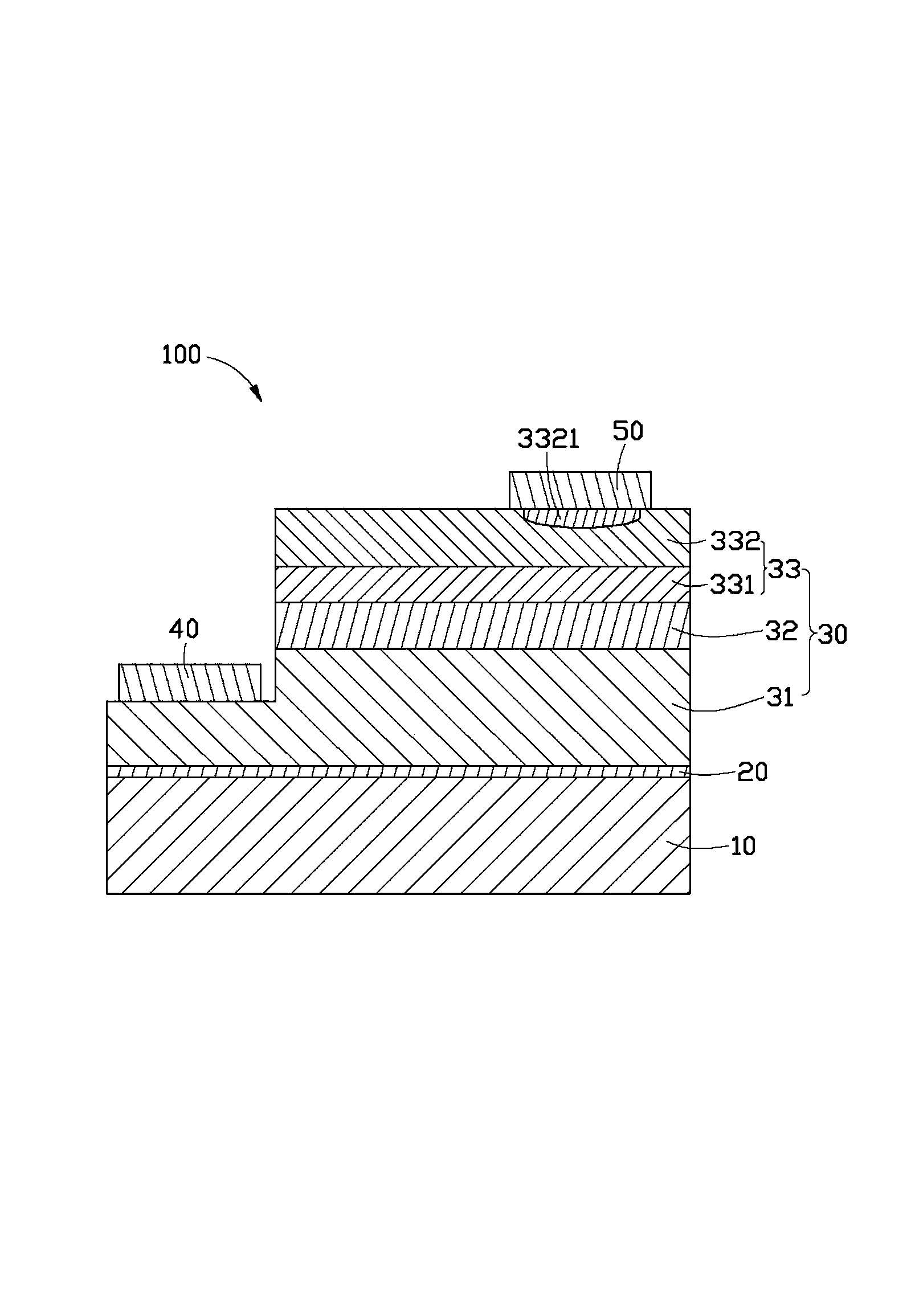

[0018] Such as figure 1 The light emitting diode die 100 provided by the first embodiment of the present invention includes in turn: a substrate 10, a buffer layer 20 formed on the substrate 10, and an epitaxial layer 30 formed on the buffer layer 20.

[0019] The substrate 10 can be made of sapphire, silicon carbide (SiC), silicon (Si), gallium nitride (GaN) and other materials. In this embodiment, it is preferably sapphire to control the manufacturing cost of the light-emitting chip.

[0020] The buffer layer 20 can be achieved by metal-organic chemical vapor deposition (MOCVD), molecular beam epitaxy (MBE) or hydride vapor phase epitaxy (HVPE), etc. The method grows on the surface of the substrate 10. Since the buffer layer 20 is formed to reduce defects caused by the lattice mismatch during the growth of the epitaxial layer 30, it can be made of a material whose lattice constant matches the epitaxial layer 30.

[0021] The epitaxial layer 30 can also be deposited by metal-organi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap