Stripping and crimping machine

An all-in-one machine and wire stripping technology, which is applied in the direction of connection, connection by deformation, line/collector parts, etc., can solve the contradiction of investment in production-scale equipment, restrict product development, and cannot afford high investment in equipment And other problems, to achieve the effect of quality assurance of crimping, reduction of working hours and cost, and accurate and consistent wire feeding position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

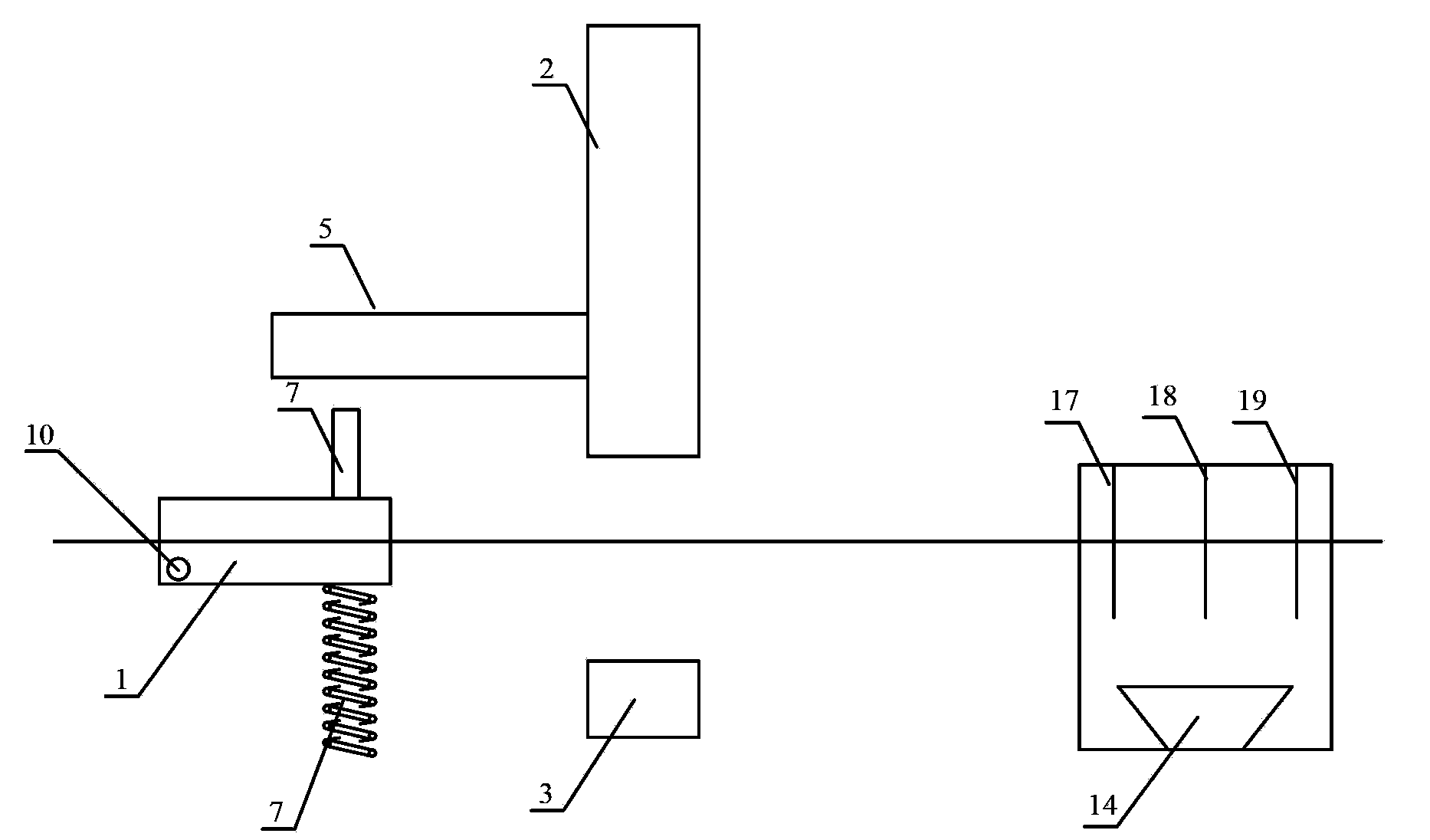

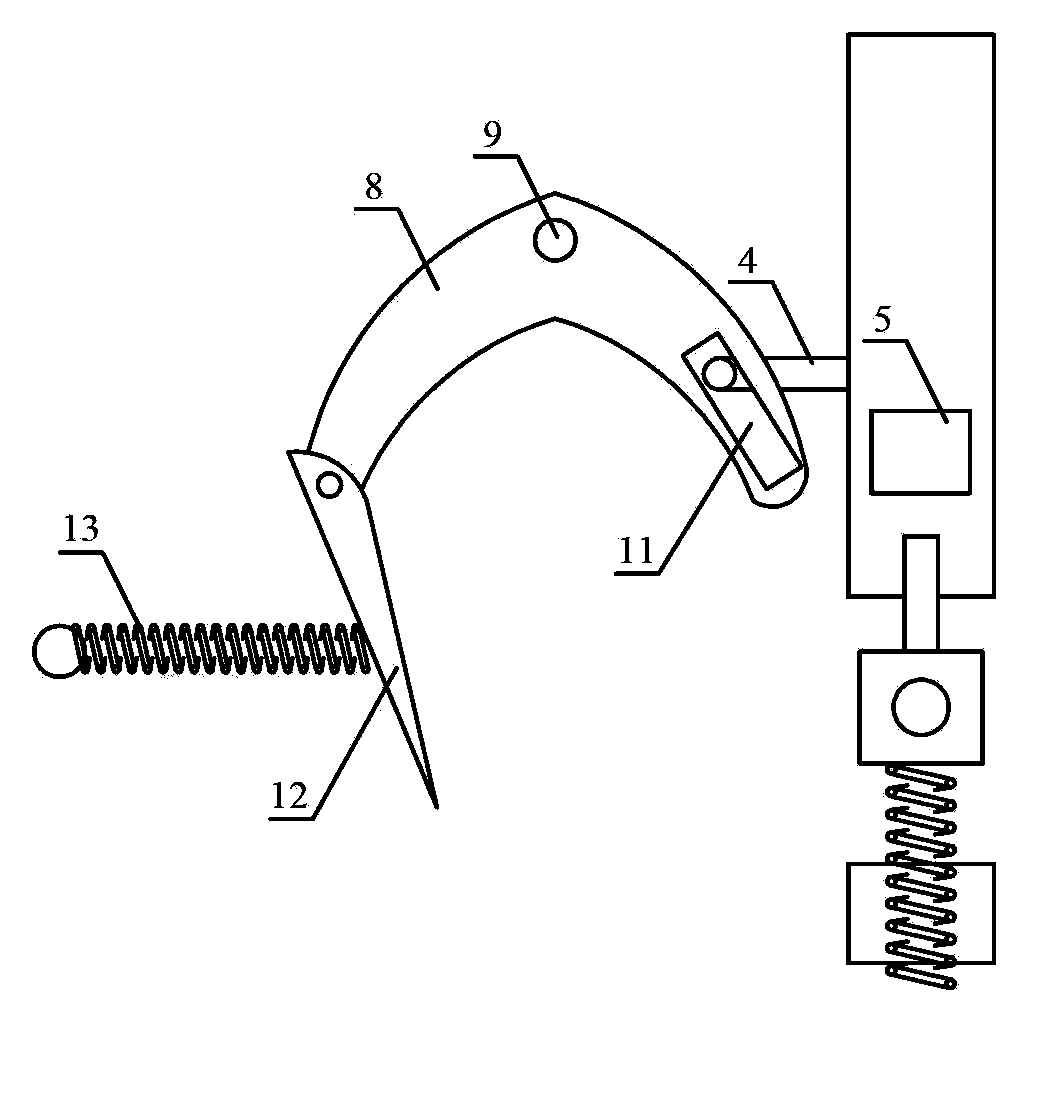

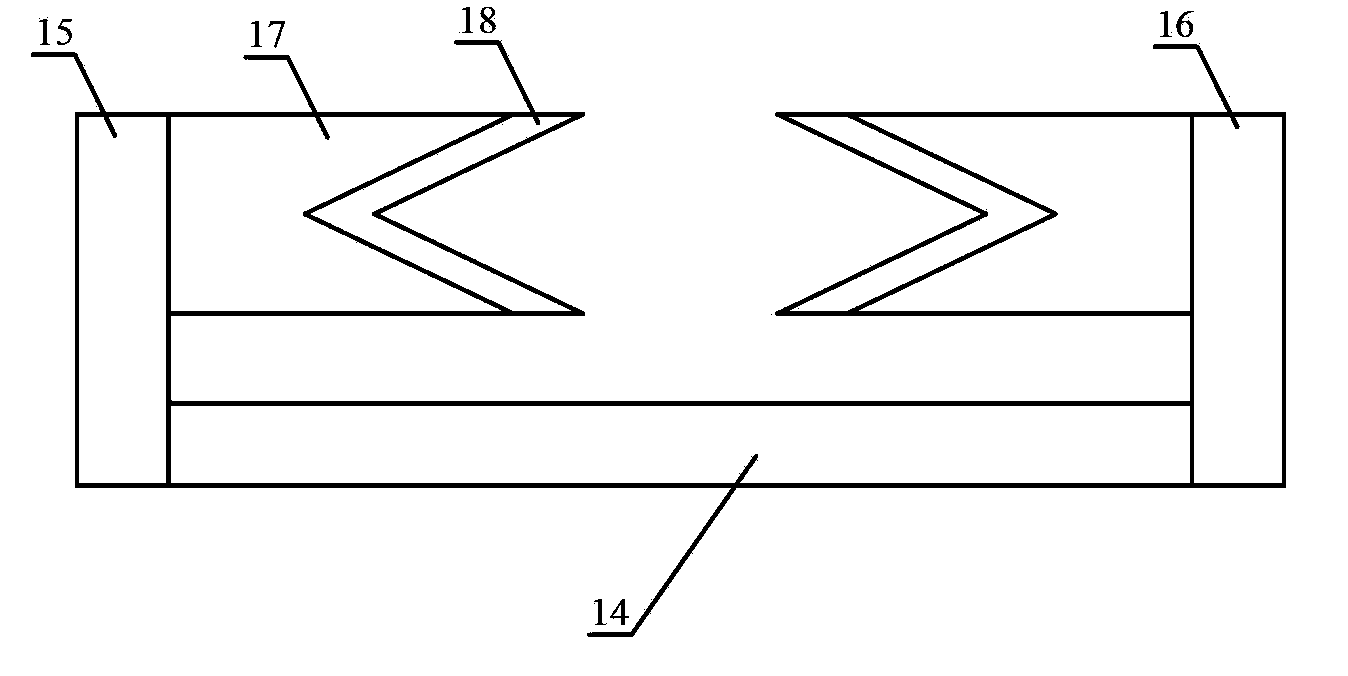

[0026] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes crimping devices and cutting and peeling devices placed in sequence before and after,

[0027] The crimping device includes a frame (not marked in the figure), and also includes a wire guide tube 1, a matched lower punch 3 and an upper punch 2, and the horizontal position of the wire guide tube 1 is higher than the lower punch 3, the upper top surface of the wire guide tube 1 is provided with a top post 7.

[0028] The upper die 2 is vertically slidingly connected with the frame up and down, and the left side of the upper die 2 is provided with a shift fork 4, and the front side of the upper die 2 is provided with a briquetting block 5, and the briquetting block 5 Located above the front of the wire guide tube 1, the wire guide tube 1 is arranged in front of the wire inlet of the lower die 3, and the lower part of the front end of the wire guide tube 1 is hinged with the frame through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com