Motor speed control device and speed control method

A speed control, motor technology, applied in the direction of AC motor control, control system, electrical components, etc., can solve problems such as implementation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the field of spindle drive, the dedicated motor for the spindle is generally driven by an inverter, and the workpiece is rotated by the dedicated motor for the spindle, and the workpiece is processed by feeding the cutting tool. However, the price of the special motor for the spindle is relatively high, so it is considered to replace the special motor for the spindle with an ordinary motor.

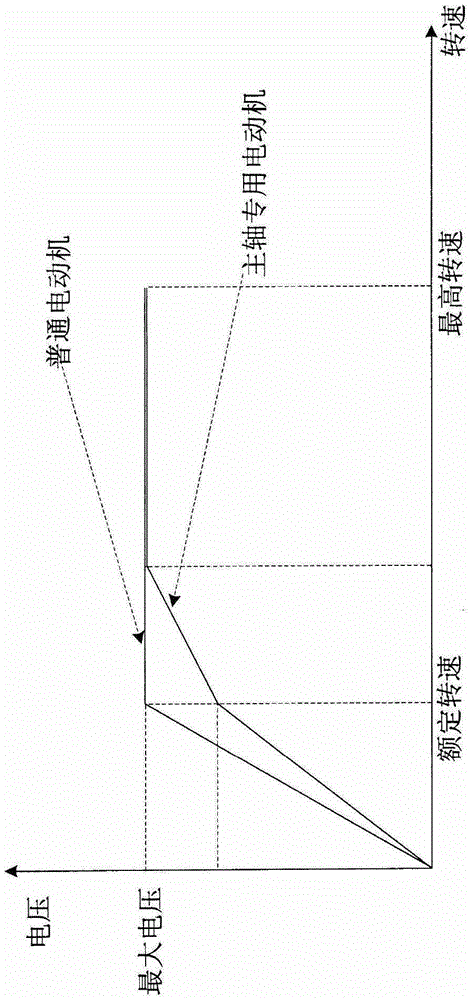

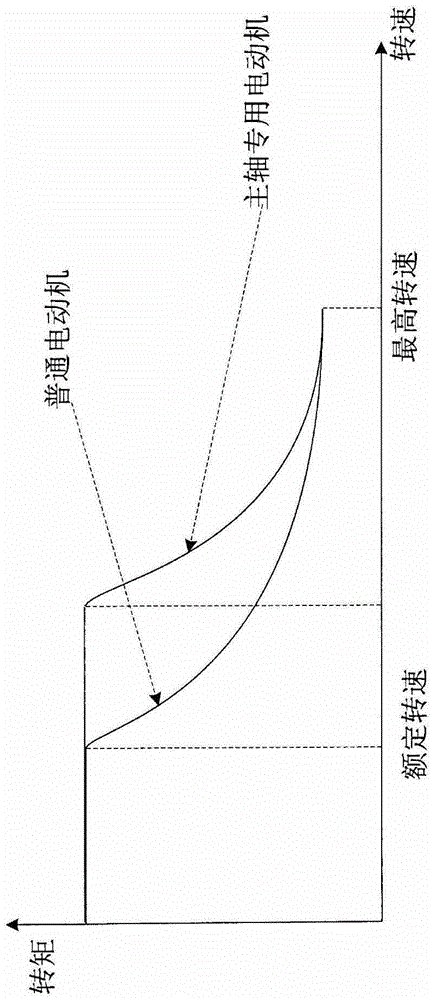

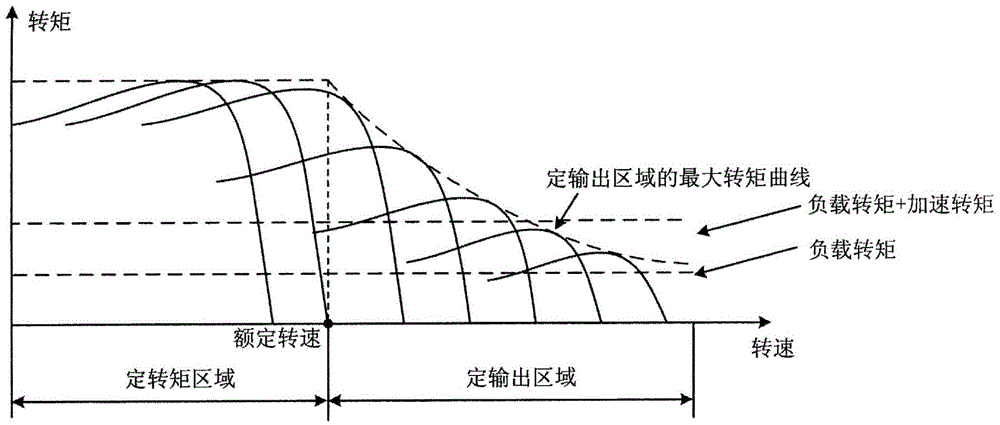

[0039] Fig. 1(A) shows the relationship curve between the speed of the spindle special motor and the general motor and the output voltage of the frequency converter, and Fig. 1(B) shows the speed-torque curve of the spindle special motor and the general motor. As shown in Figure 1(A), when an ordinary motor reaches the rated speed (for example, 1500rpm), the output voltage of the frequency converter reaches the maximum value, which is called the voltage saturation state. Since the output voltage reaches the maximum value, the power of the motor is also limited, and the power of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com