Super-lift winch control system and crane using the same

A control system and controller technology, applied in the field of super hoisting winch control systems and cranes, can solve problems such as affecting the effectiveness of the super hoisting device and losing its effectiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

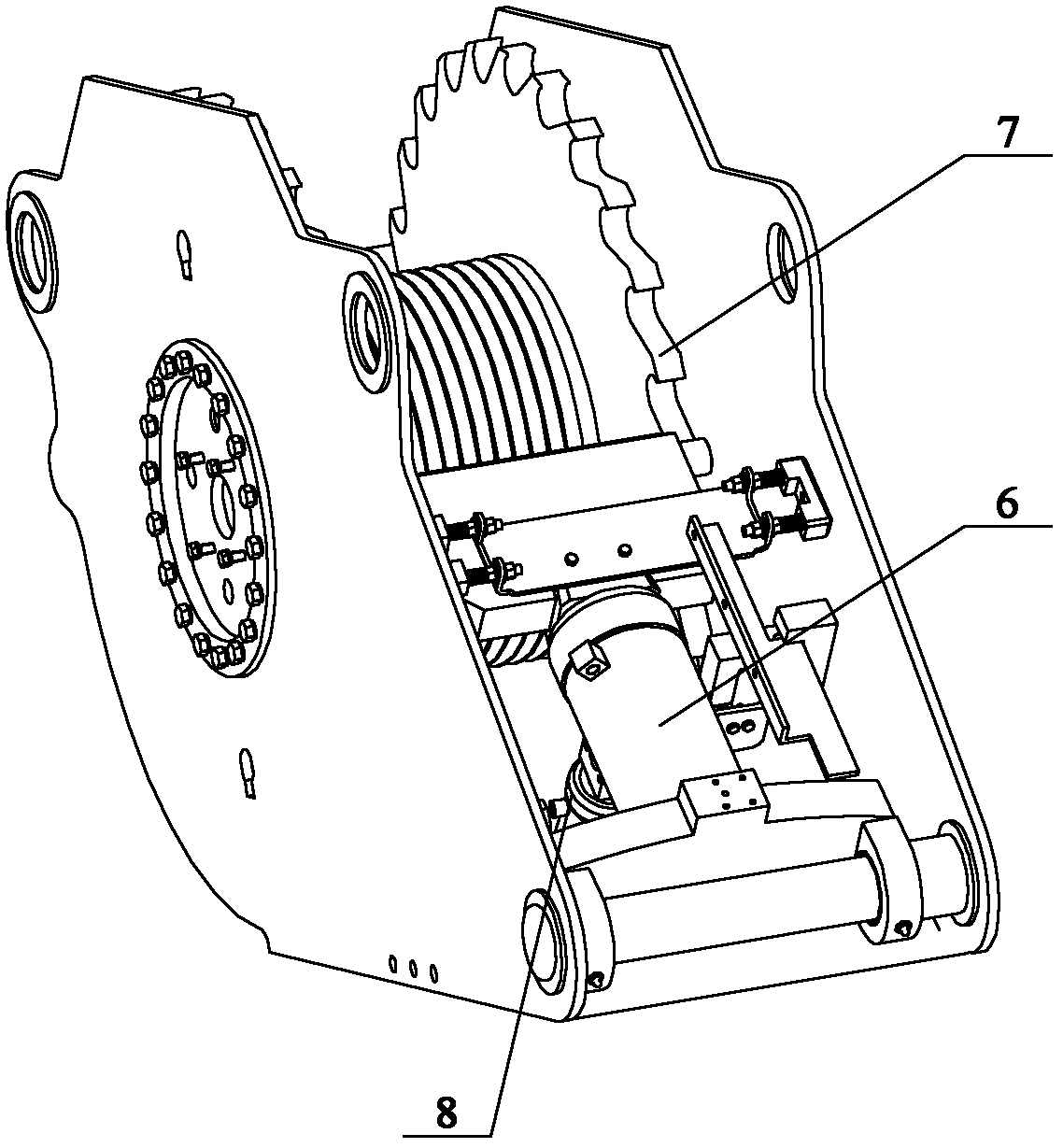

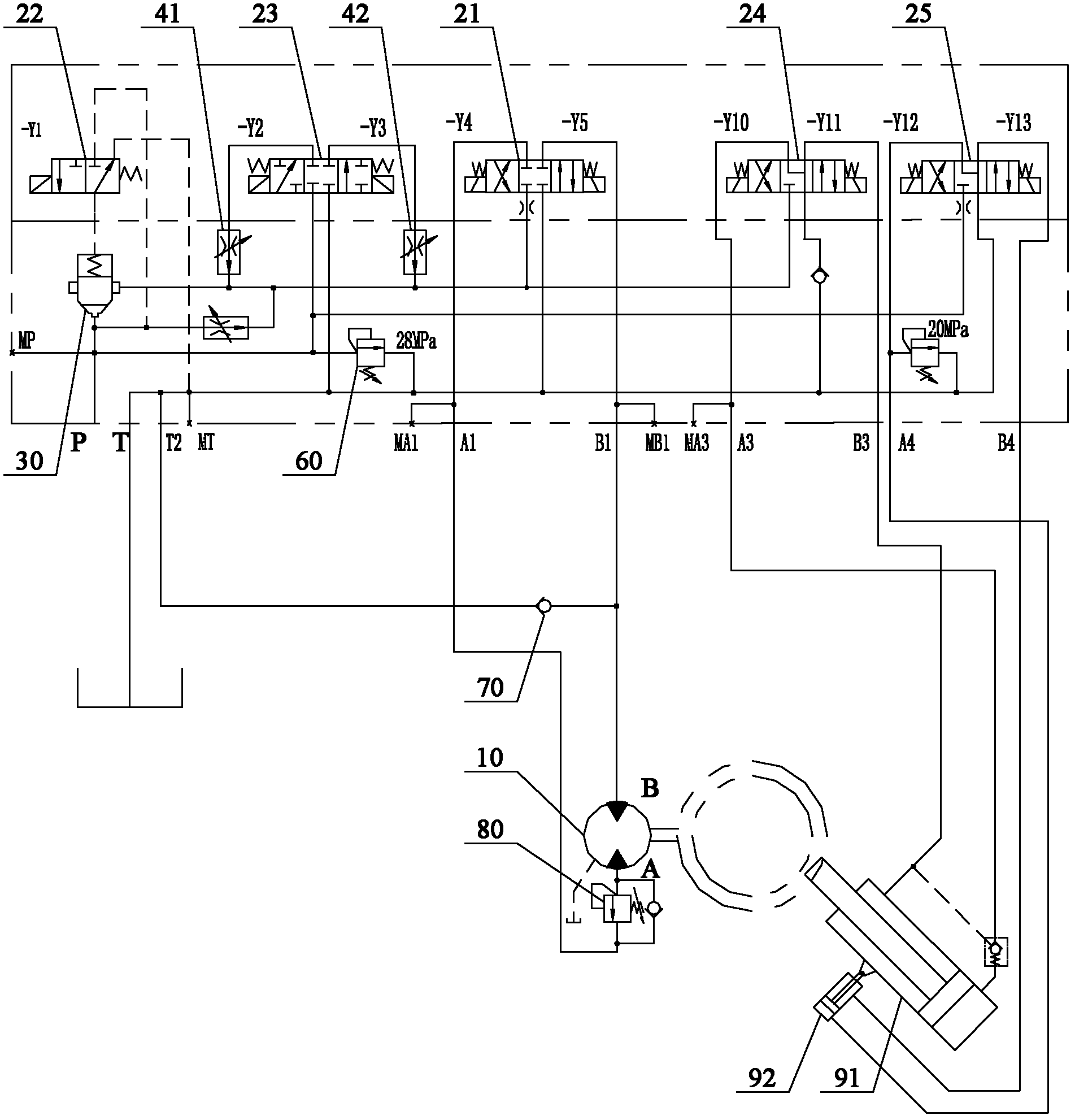

[0029] The core of the present invention is to provide a super-lift winch control system applied to the super-lift device of a crane. The control system can control the output of pressure oil with a certain flow rate to the opening of the super-lift motor when the boom is extended. Therefore, it is ensured that there is sufficient counter torque when the steel wire rope is released during the boom extension process, thereby effectively avoiding the occurrence of the stall phenomenon. The present embodiment will be described in detail below in conjunction with the accompanying drawings.

[0030] Without loss of generality, this embodiment will be described in detail with a wheeled crane as the main body.

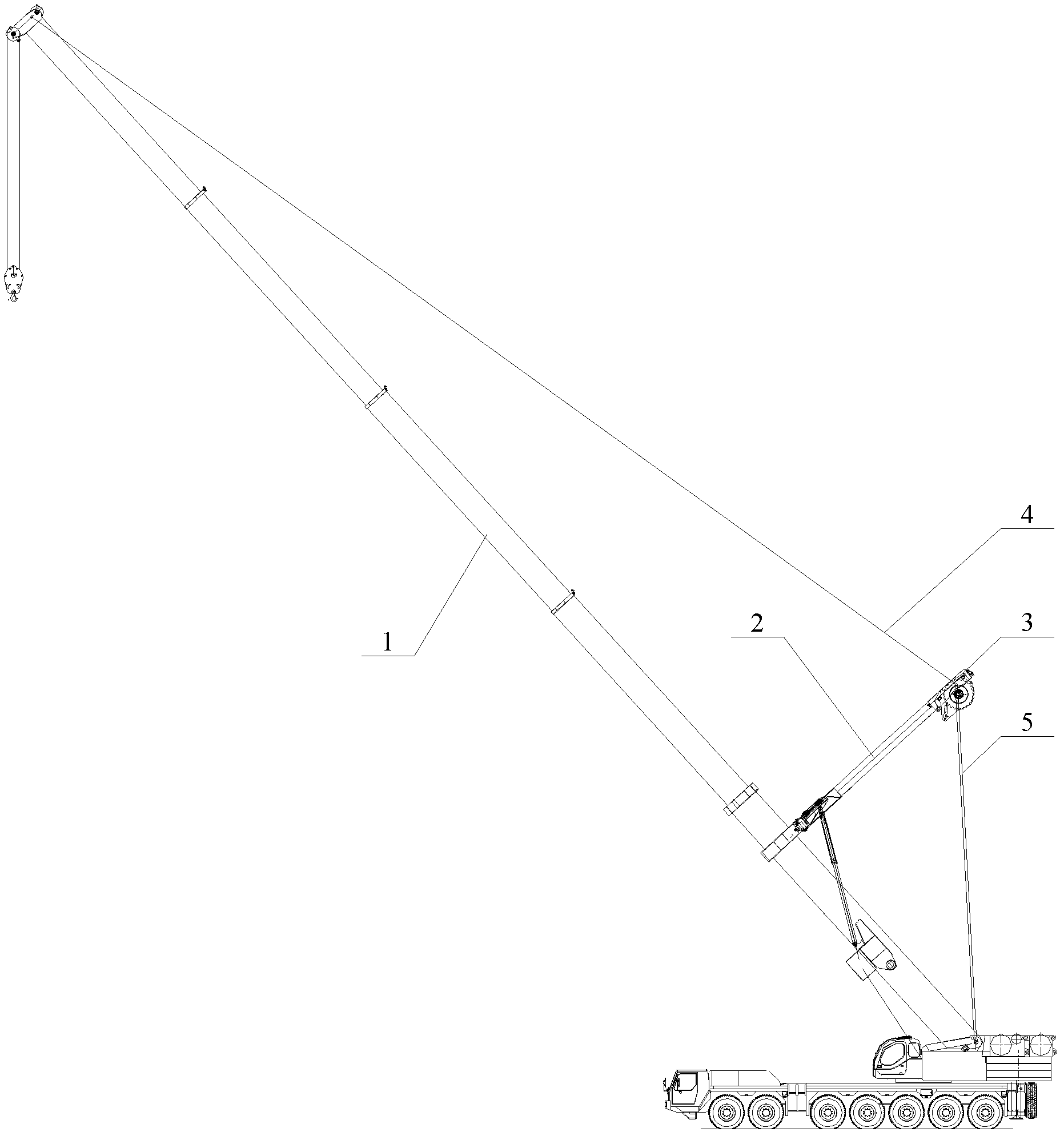

[0031] Same as the prior art, the wheeled crane includes a wheeled chassis, a telescopic boom, and a super-lifting device arranged on the telescopic boom. The above-mentioned functional components are exactly the same as the prior art. For details, please refer to figure 1 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com