Fixed quantity supply device

A quantitative supply, shell technology, applied in the direction of transportation and packaging, loading/unloading, etc., can solve the problems of reducing processing capacity, inappropriateness, obstructing valve rotation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

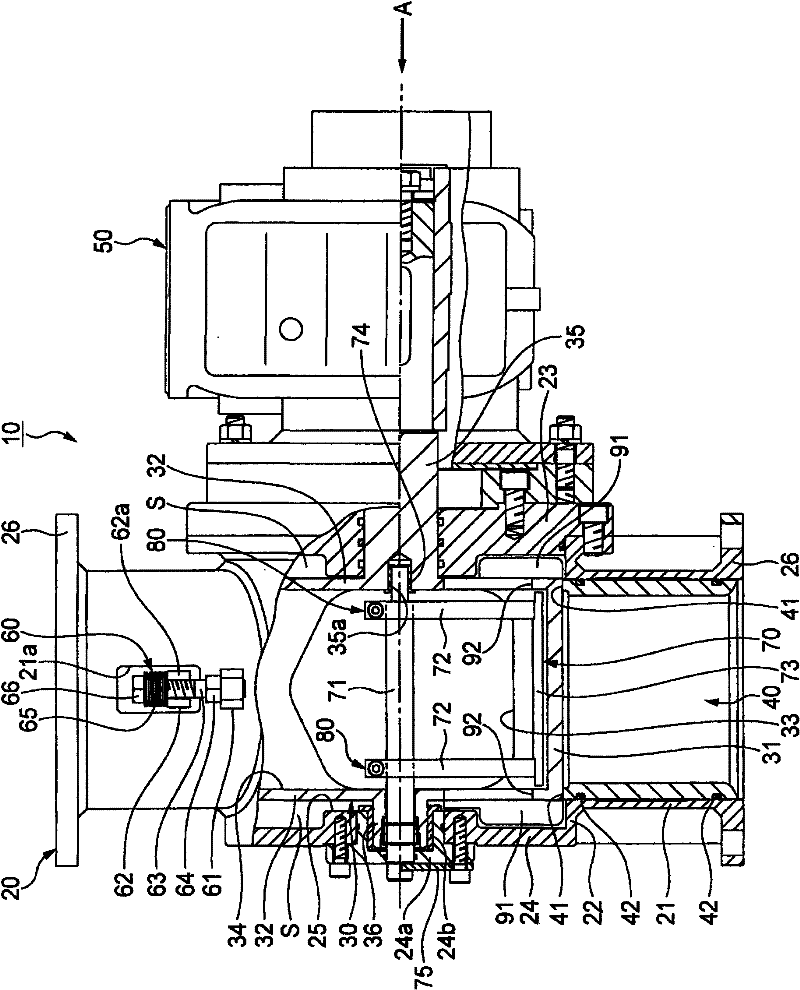

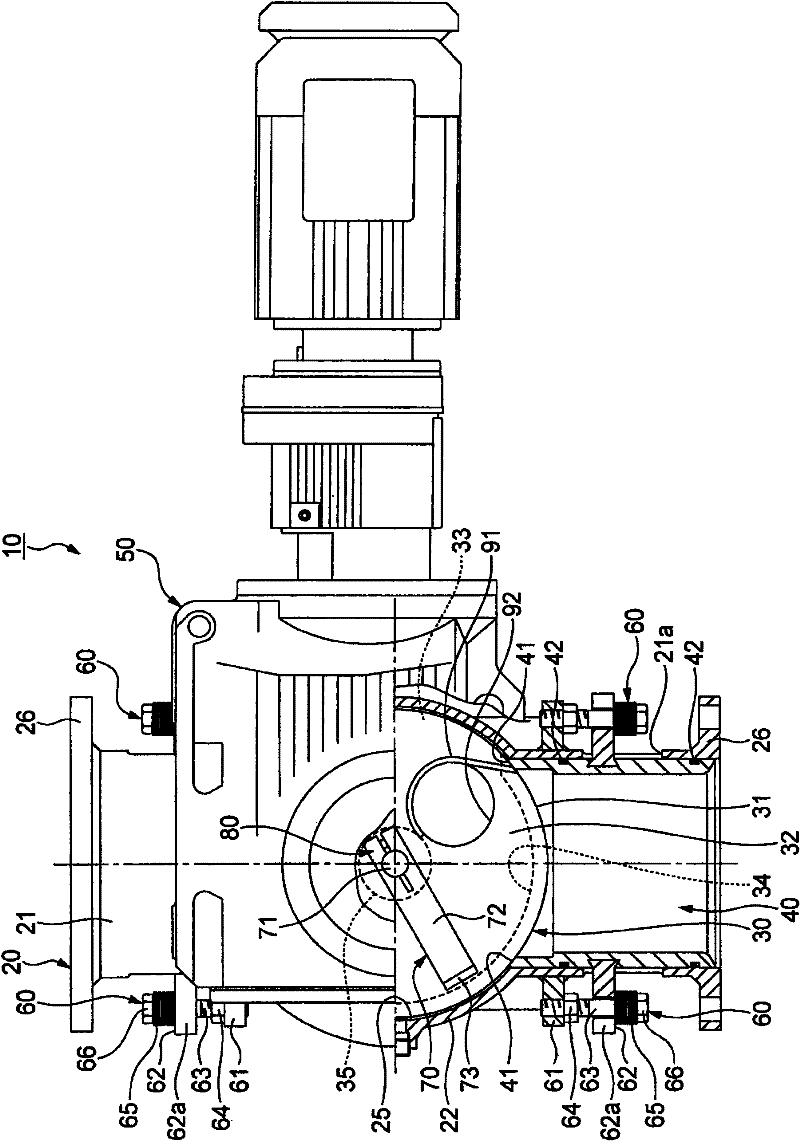

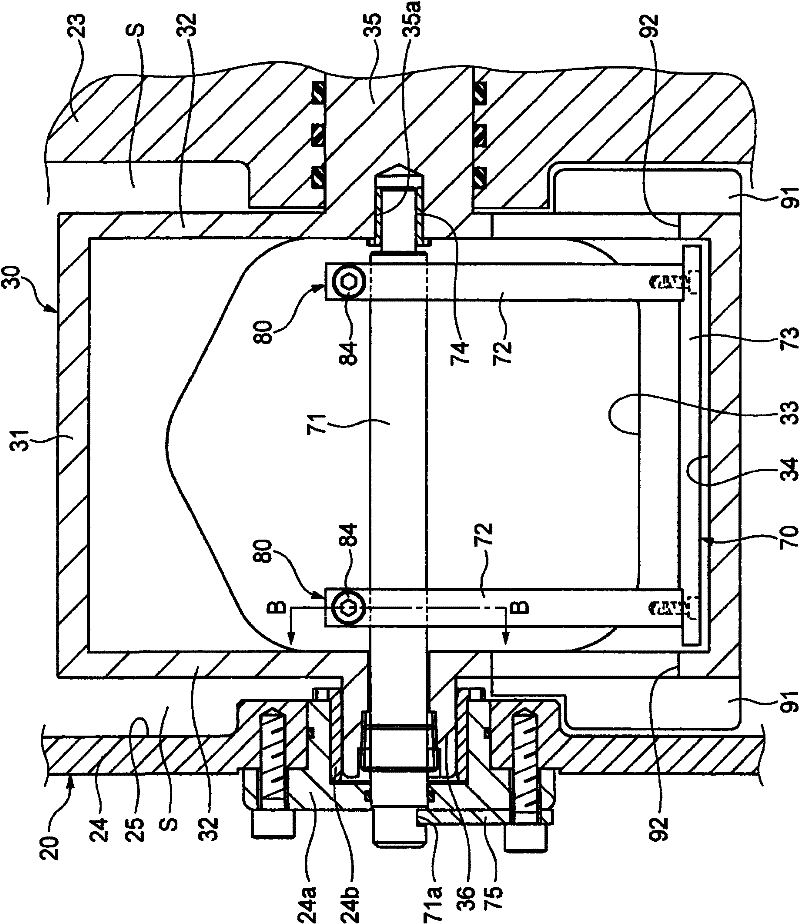

[0055] Next, an embodiment of the quantitative supply device of the present invention will be described in detail with reference to the drawings. In addition, in this embodiment, the quantitative supply device whose to-be-transferred object is powder is taken as an example and demonstrated.

[0056] Such as figure 1 and figure 2 As shown, the quantitative supply device 10 of the present embodiment is provided with: a cylindrical housing 20, which is arranged in the housing 20, and can be arranged around the first and second rotating shafts 35, 36 arranged to cross the direction of the cylindrical axis of the housing 20. The core rotation valve 30 is inserted into both sides of the casing 20 in the direction of the cylindrical axis, and a pair of seat rings 40 are in close contact with the valve 30 for sealing. Drive device 50 .

[0057] The casing 20 includes: a first cylindrical portion 21 as a powder transfer path; Part 22, one end portion of the second cylindrical port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com