Oil or fat composition

A kind of oil composition and oil technology, which is applied in the direction of edible oil/fat, food science, fatty acid oxidation, etc., can solve the problem of limited oil use range, achieve the effect of suppressing heating odor and improving flowering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

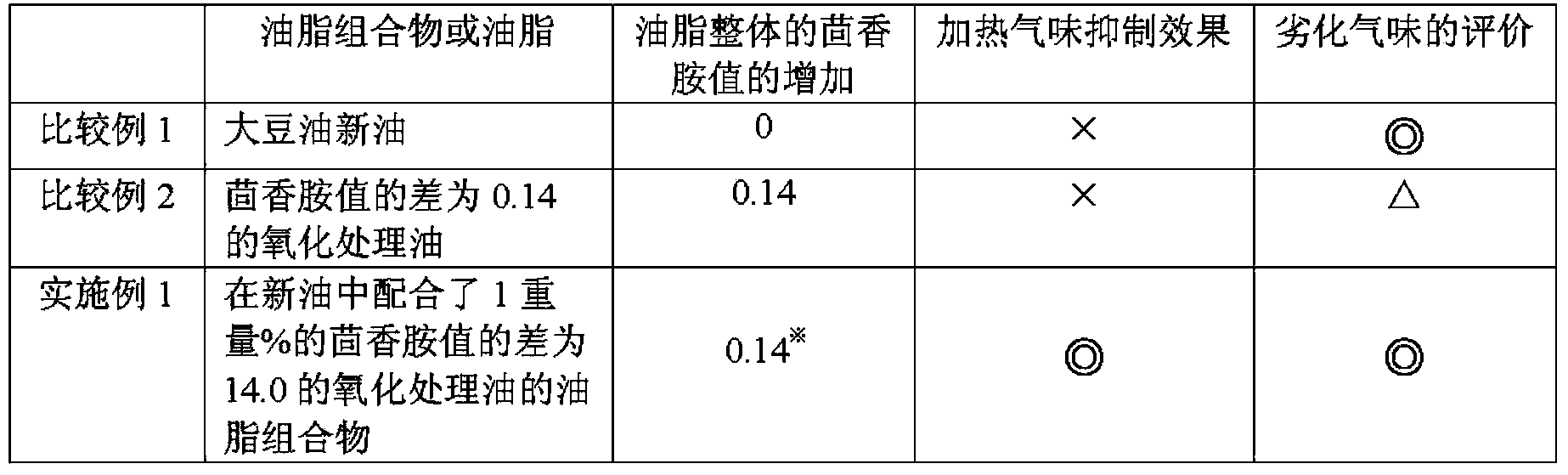

[0040] [Example 1] Addition test of oxidized oil

[0041] The heating odor suppression effect of the oil and fat composition of this invention is exhibited for the first time by adding a small amount of oxidized fats and oils to a base oil. Experiments to verify this were carried out.

[0042] First, 250 g of fresh soybean oil with an anisidine value of 2.07 (product name: soybean white kerosene oil, manufactured by J-OIL MILLS, Inc.) was put into a stainless steel beaker with a capacity of 500 mL, and immersed in an oil bath at a temperature of 134°C. . Then, heat and stir while blowing air into the oil to oxidize the oil. By changing the heating time, two kinds of oxidation-treated soybean oils having differences in anisidine values before and after oxidation treatment of 0.14 and 14.0 were obtained.

[0043] The oil and fat combination of the present invention was obtained by adding 1% by weight of oxidized oil having a difference in anisidine value of 14.0 to soybean ...

Embodiment 2~9

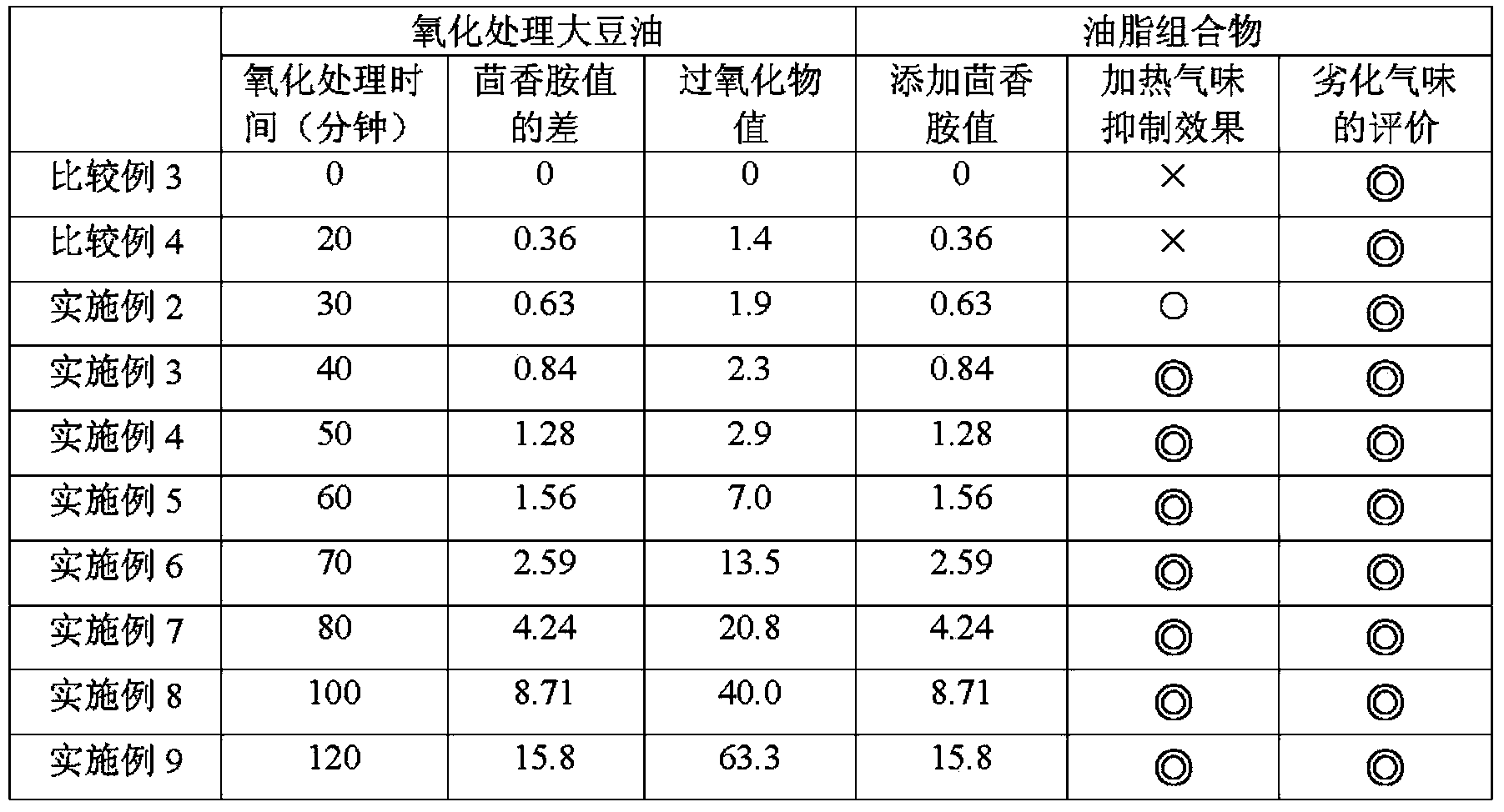

[0068] [Examples 2-9] Change test of oxidized oil (1)

[0069] An oil and fat composition in which oxidized oils having different degrees of oxidized treatment were blended as oxidized oils to a base oil was prepared, and the effect of suppressing heating odor was studied.

[0070] First, 250 g of the above fresh soybean oil was put into a 500-mL stainless steel beaker, immersed in an oil bath at a temperature of 134° C., and then heated and stirred while blowing air. Soybean oil was sampled at different times, resulting in poor oxidized soybean oil with the anisidine values shown in Table 2. The peroxide value of oxidized soybean oil was determined. The results are shown in Table 2.

[0071] By adding 1% by weight of the above-mentioned oxidized soybean oil to palm fractionated oil soft part (iodine value 67, manufactured by J-OIL MILLS, Inc.) as base oil, fats and oils having the anisidine value added in Table 2 were obtained combination. For comparison, a composition ...

Embodiment 10~18

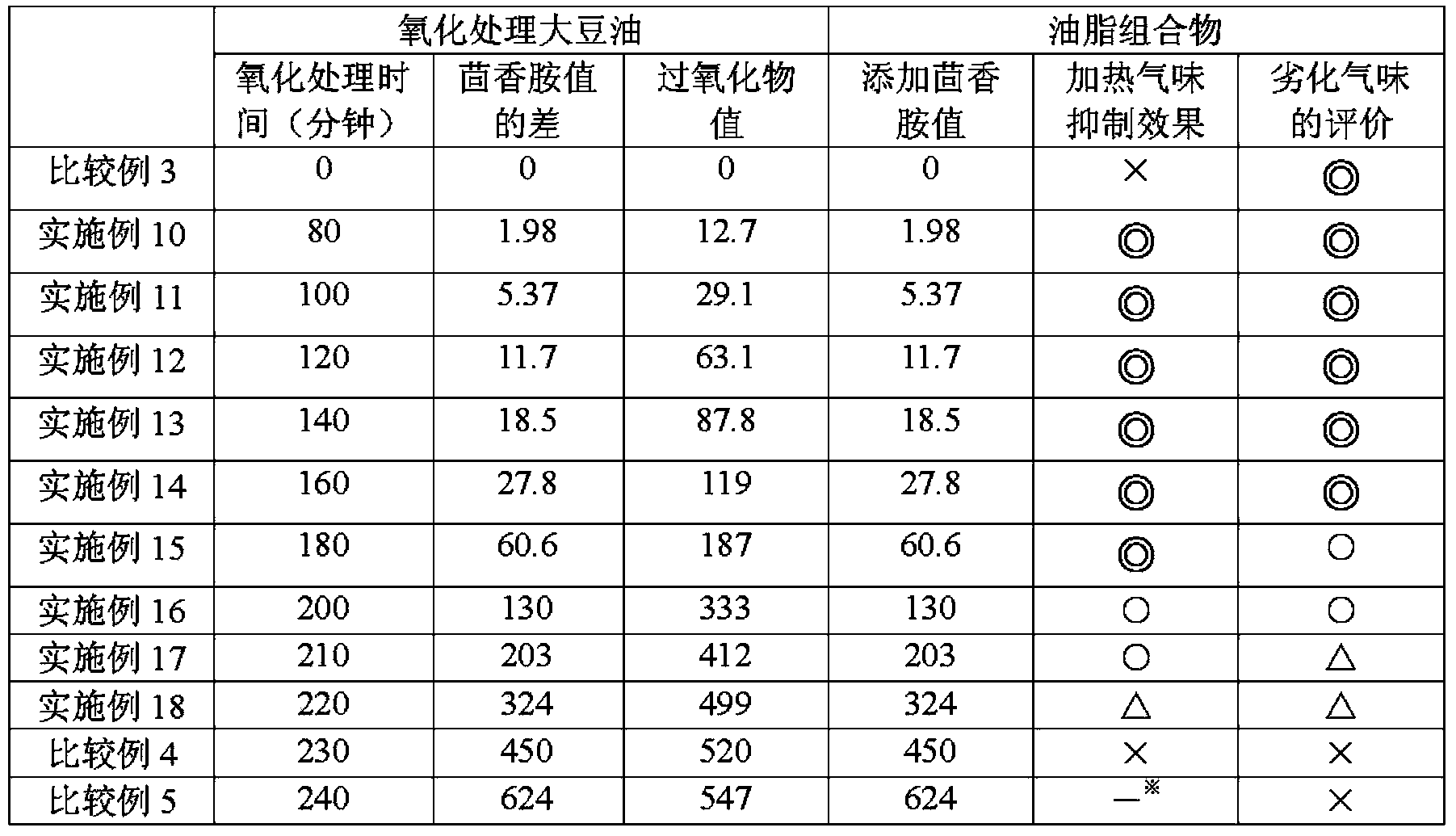

[0076] [Examples 10-18] Change test of oxidized oil (2)

[0077] In the same manner as in Example 2, an oil and fat composition in which an oxidized oil was blended with a base oil was prepared, and the heating odor suppression effect of this composition was verified. 250 g of the above fresh soybean oil was put into a stainless steel beaker, immersed in an oil bath at a temperature of 134° C., and then heated and stirred while blowing air. Soybean oil was sampled at different times to obtain poor oxidized soybean oil with the anisidine values shown in Table 3. The peroxide value of oxidized soybean oil was determined. The results are shown in Table 3. By adding 1% by weight of these oxidized soybean oils to the above-mentioned palm fraction soft part as a base oil, an oil and fat composition having an added anisidine value shown in Table 3 was obtained.

[0078] 8 g of the above-mentioned oil and fat composition was put into the above-mentioned glass container, and heate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com