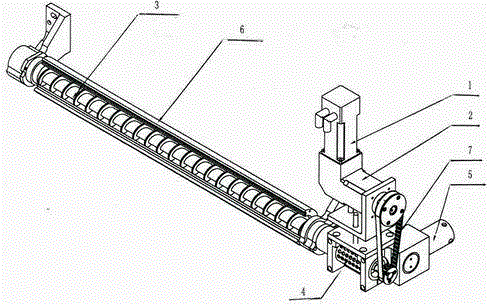

Stem discharging device for Molins series cigarette making machine

A cigarette machine and a series of technologies, which are applied in the field of stem-discharging devices, can solve problems such as waste and clogging, and achieve the effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The embodiment is described in detail in conjunction with the accompanying drawings. The present invention is provided with a stem suction chamber 4 at the rear end of the tobacco stem slot 6, and an air suction port 5 is installed on one side of the stem suction chamber. The screw conveyor 3 in the sucking stem chamber is equipped with a servo motor 1 on the sucking stem chamber, and the servo motor is connected to the screw conveyor through a reducer 2 and a synchronous belt 7. When the equipment is in normal operation, the tobacco stems falling in the tobacco stem groove are brought into the stem suction chamber in time by the screw propeller, and then sucked out by the suction fan through the suction port. It can effectively prevent the clogging of tobacco stems and the occurrence of tobacco shreds being taken away.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap