Novel workpiece conveyer

A technology for conveying devices and workpieces, applied in the directions of transportation and packaging, conveyors, mechanical conveyors, etc., can solve problems such as labor and trouble, and achieve the effect of improving work efficiency and achieving remarkable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] specific implementation plan

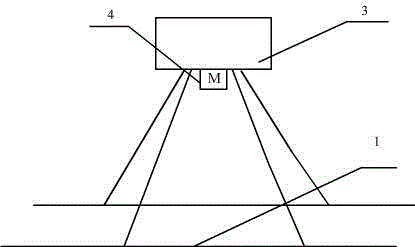

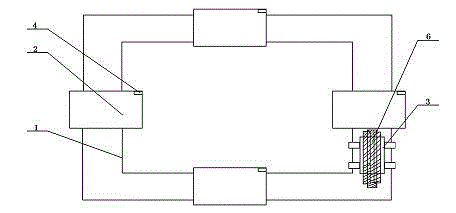

[0011] like figure 1 , figure 2 Shown is a new type of workpiece transport device, which includes a guide rail 1, a delivery trolley 3, a motor 4 and a control switch 5, the guide rail 1 is installed in each processing workshop 2, and the guide rail 1 is surrounded by a rectangle; the delivery trolley 3 is installed on the guide rail 1, and the delivery trolley 3 is used to transport the workpiece 6 to be processed; the motor 4 is installed under the delivery trolley 3, and the motor 4 is the transmission part of the delivery trolley 3; the control The switch 5 is installed in each processing workshop 2 respectively, and the control switch 5 is used to control the motor 4 to impel the delivery trolley 3 to move on the guide rail 1 .

[0012] During work, the control switch 4 of each processing workshop controls the movement of the delivery trolley 3 on the guide rail 1, and quickly transports the workpiece 5 to be processed to each proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com