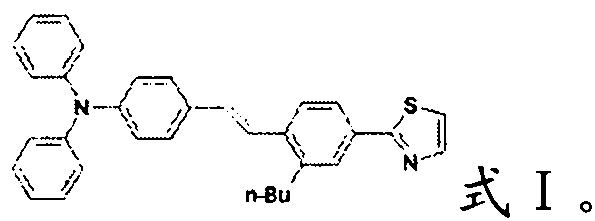

A compound used as a polyester fabric dye

A technology of polyester fabrics and compounds, applied in styrene-based dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of poor comprehensive fastness, low dye sublimation fastness, poor dyeing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0012] Synthetic steps:

[0013] (1) Add 0.4mol 2-n-butyl-4-bromotoluene and 14.4g benzoyl peroxide in the reaction flask equipped with mechanical stirring and reflux condenser, after stirring and heating to reflux, 71.2g (0.4mol ) 2-bromo-2,5-diketone pyrrole (NBS) was added to the reaction flask in batches within 20 minutes, heated to reflux for 2 hours, and the reaction yield was 65% (GC). The reaction solution was neutralized with sodium carbonate, concentrated, dissolved with industrial absolute ethanol (1g: 1mL) under reflux, cooled to -15°C for recrystallization, the purity was about 90% (GC). Its purity was >99% after multiple recrystallizations.

[0014] (2) Under the protection of nitrogen, add 0.05mol triphenylamine and 100mL DMF to the reaction flask equipped with mechanical stirring and reflux condenser, cool to 5°C in an ice bath, slowly add 0.1mol phosphorus oxychloride dropwise under stirring, dropwise add Upon completion, the ice bath was removed and allowed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com