Measuring method of flatness of honeycomb cores of combined frame structures

A measurement method and frame structure technology, applied in the field of measurement, can solve problems such as lack of honeycomb core flatness measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The method for preparing the micro-arc oxidation film layer with photocatalytic function provided by the present invention is specifically realized through the following steps:

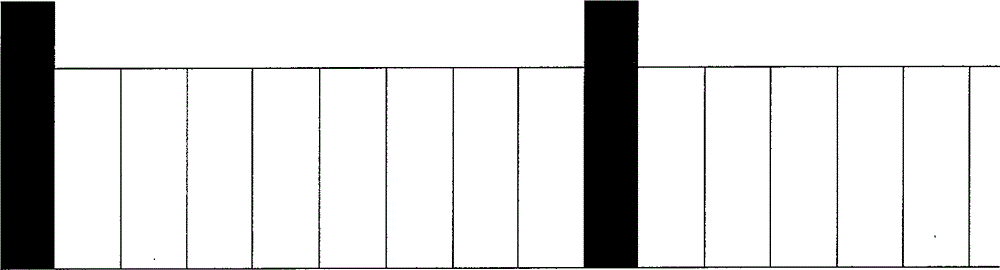

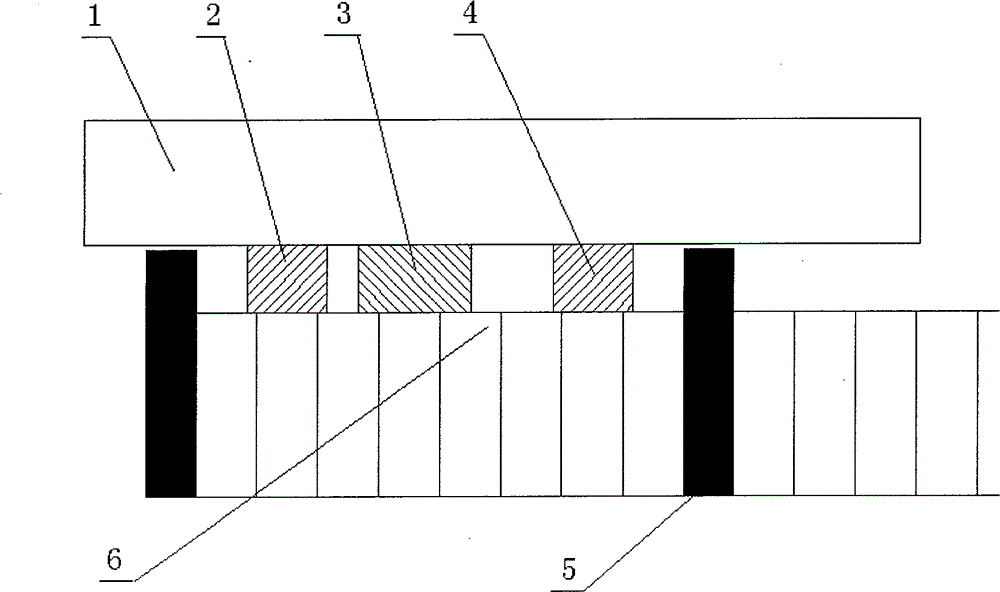

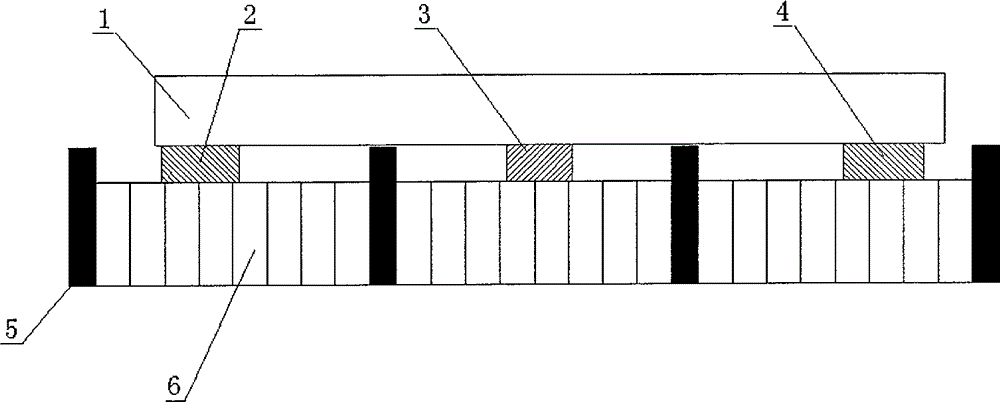

[0022] The first step is to measure the flatness, choose two gauge blocks of the same size as the reference gauge block, and then select gauge blocks of different sizes to test the plug, when the gauge block of the test plug just passes through, record the test plug gauge value. See Figure 4 Figure 5 .

[0023] The second step is data processing to calculate the flatness of the small honeycomb core.

[0024] The calculation first takes the value of one of the diagonals as a benchmark, and converts the value of the other diagonal. Equalize the values at both ends of each diagonal line. After the two diagonal lines are respectively contoured, find the maximum value and subtract the minimum value from all the measured data to obtain the flatness of the honeycomb core. See the attached Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com