Instruments and methods for cable-stayed bridge cable replacement project monitoring

A technology for engineering monitoring and cable-stayed bridges, which is applied in the testing of instruments, measuring devices, machinery/structural components, etc. Force adjustment, inability to effectively control the risk of cable-stayed bridge replacement engineering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

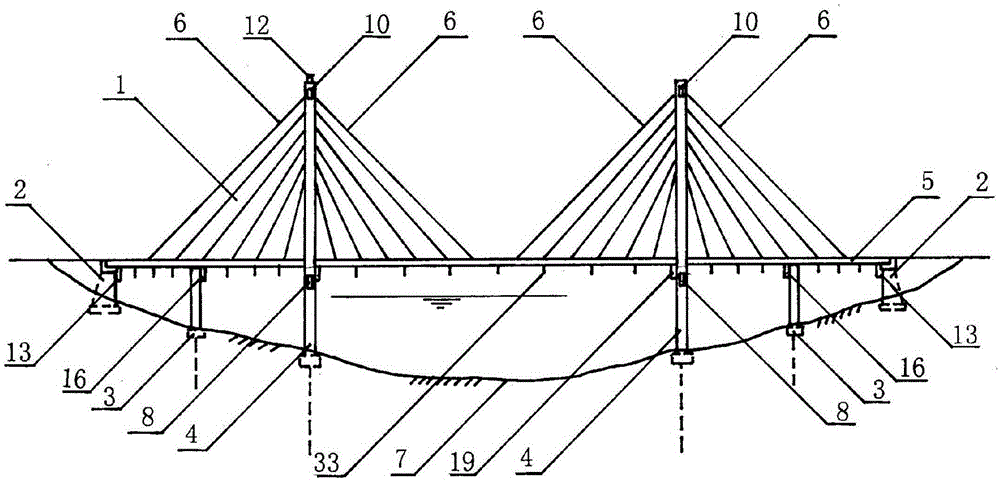

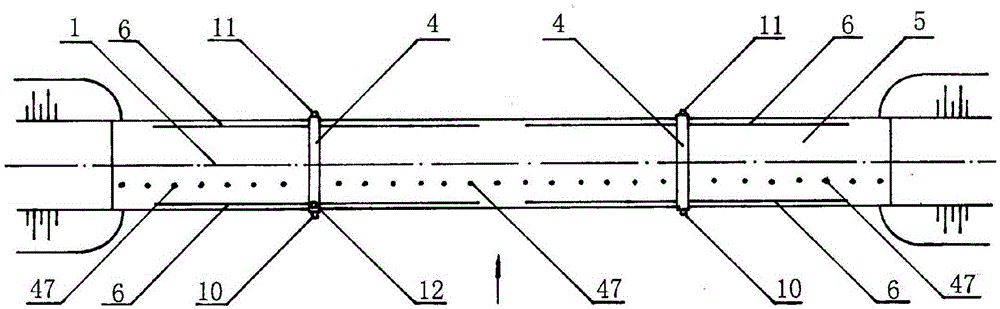

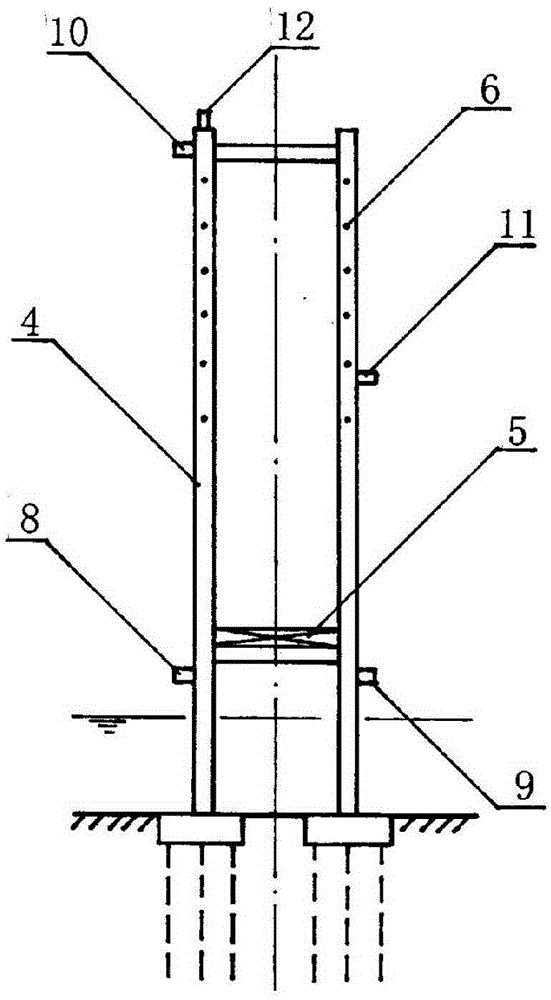

[0044] see Figure 1 to Figure 14, is the instrument equipment of a kind of cable-stayed bridge cable changing project monitoring of the present invention, has included the monitoring of abutment 2, bridge pier 3, cable tower 4, girder 5, stay cable 6 to cable-stayed bridge 1, is characterized in that : The abutment 2, pier 3, cable tower 4, main girder 5, and stay cable 6 of the cable-stayed bridge 1 adopt theodolite, level, cable tower swing test laser emission device I8, cable tower swing test laser emission device II9, Cable tower swing target device Ⅰ10, cable tower swing target device Ⅱ11, wind speed, wind direction and wind frequency meter 12, pull-wire photoelectric displacement sensor a13, pull-wire photoelectric displacement sensor b14, pull-wire photoelectric displacement sensor c15, pull-wire photoelectric displacement sensor d16 , pull-wire photoelectric displacement sensor e17, pull-wire photoelectric displacement sensor f18, pull-wire photoelectric displacement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com