Optical waveguide pulse coupler and manufacturing method thereof

A technology of pulse coupling and optical waveguide, applied in the field of integrated optics and optical waveguide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

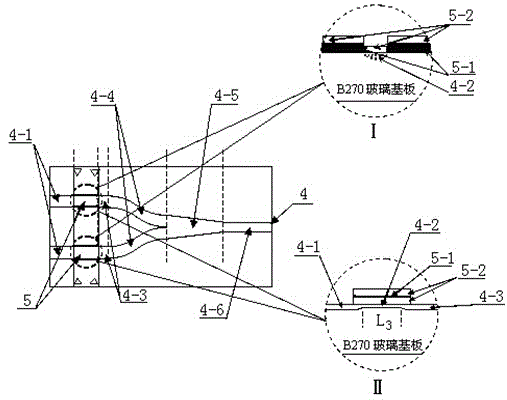

[0031] The basic structure of the core optical path of the optical waveguide pulse coupler is as follows: figure 1 As shown, it consists of an inverted Y-branch waveguide 4 and two composite waveguides 5 symmetrically prepared at the two branch positions of the inverted Y-branch waveguide 4. The inverted Y-branch waveguide 4 is prepared on the upper surface of a glass substrate. The glass substrate can be glass such as B270, or optical glass such as BK7 or K9. The Y-branch waveguide 4 consists of two input straight waveguides 4-1 with a length of 5 mm, two cut-off straight waveguides 4-2, two transfer straight waveguides 4-3, two curved waveguides 4-4, and a wedge-shaped transition waveguide 4- 5 and an output straight waveguide 4-6 are sequentially and symmetrically connected in a Y shape. The widths of two input straight waveguides 4-1, two cutoff straight waveguides 4-2, two transfer straight waveguides 4-3, two curved waveguides 4-4 and one output straight waveguide 4-6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com