Track anti-slip control method, device and milling machine

A technology of slip control and control method, which is applied in the field of crawler anti-skid control and milling machine, and can solve the problems of hydraulic motor damage and manual anti-skid operation that cannot be performed in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

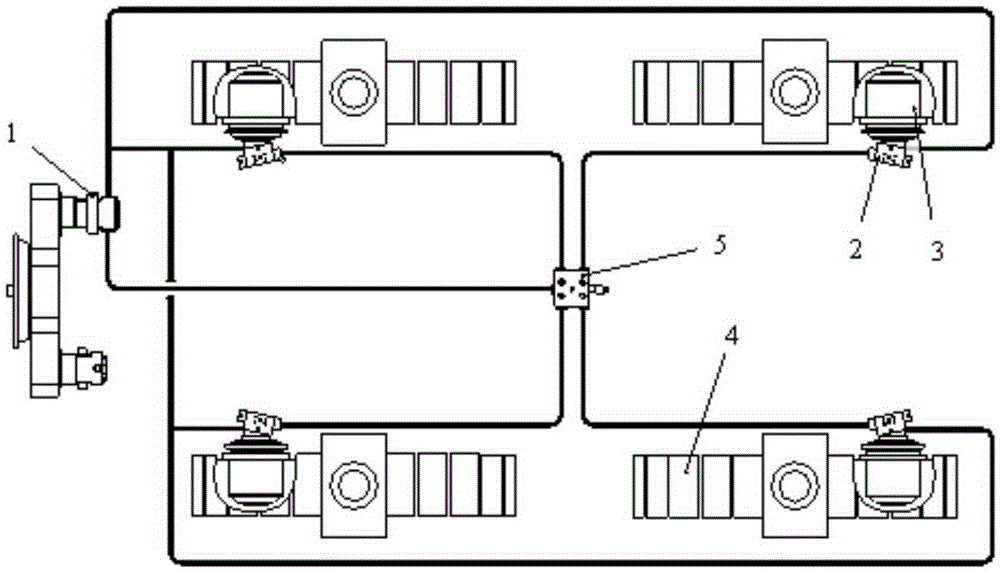

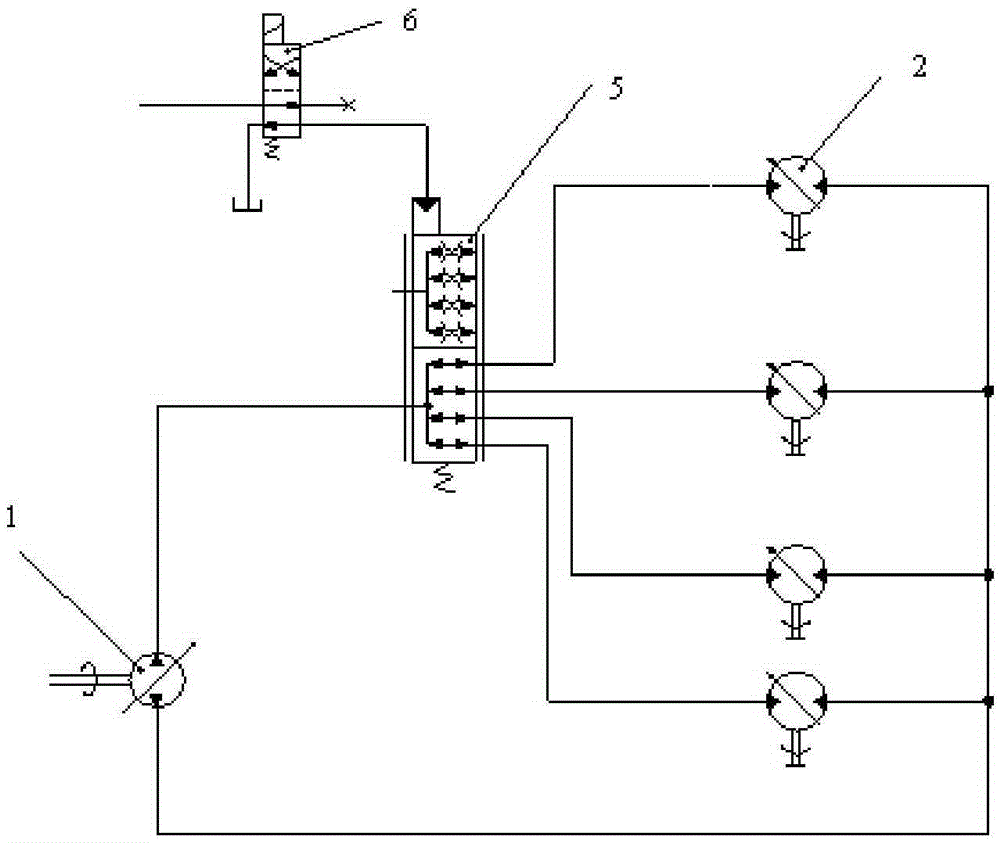

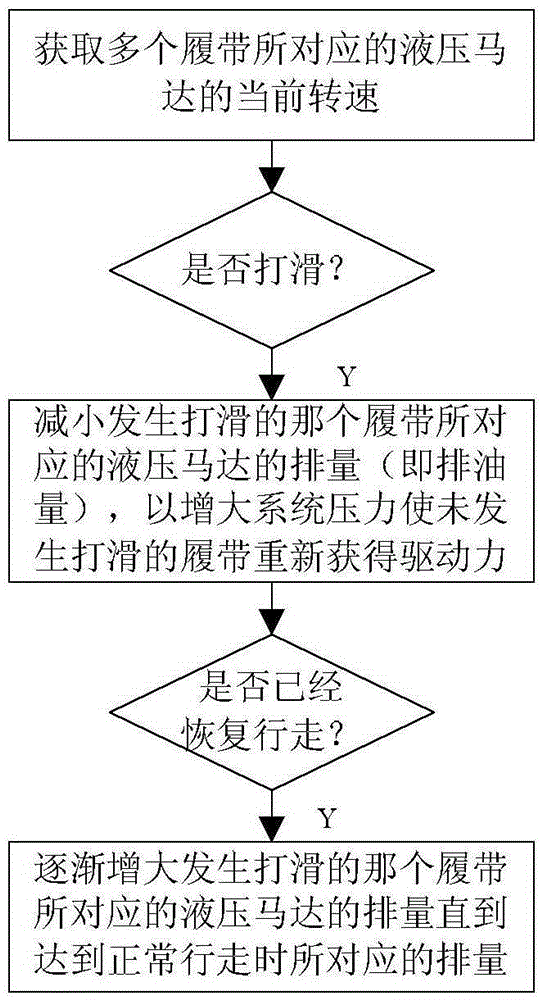

Image

Examples

Embodiment Construction

[0034] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

[0035] In the Chinese utility model patent with the application number CN201120474723.7 titled "An Automatic Anti-skid Control Device for a Fully Hydraulic Tire Roller", an anti-skid control device is disclosed (please refer to its paragraph 0014). However, in this In the anti-skid control device, it calculates the current running speed of each driving wheel of the whole machine through the controller, and the display will prompt the current running speed of the whole machine. When the operator finds from the display that the rotation speed of the wheels on both sides is different due to the wheel slipping or suspension on one side of the whole machine, the operator needs to press the differential switch for automatic anti-skid. When the differential switch is pressed, the controller judges that the differential sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com