Sewage treatment device

A sewage treatment device and sludge technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of increasing the construction cost of sewage treatment stations, inconvenient management and operation, The structure of the sewage treatment tank is not reasonable enough to achieve the effect of improving the bad situation of suspended solids treatment and improving the process method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

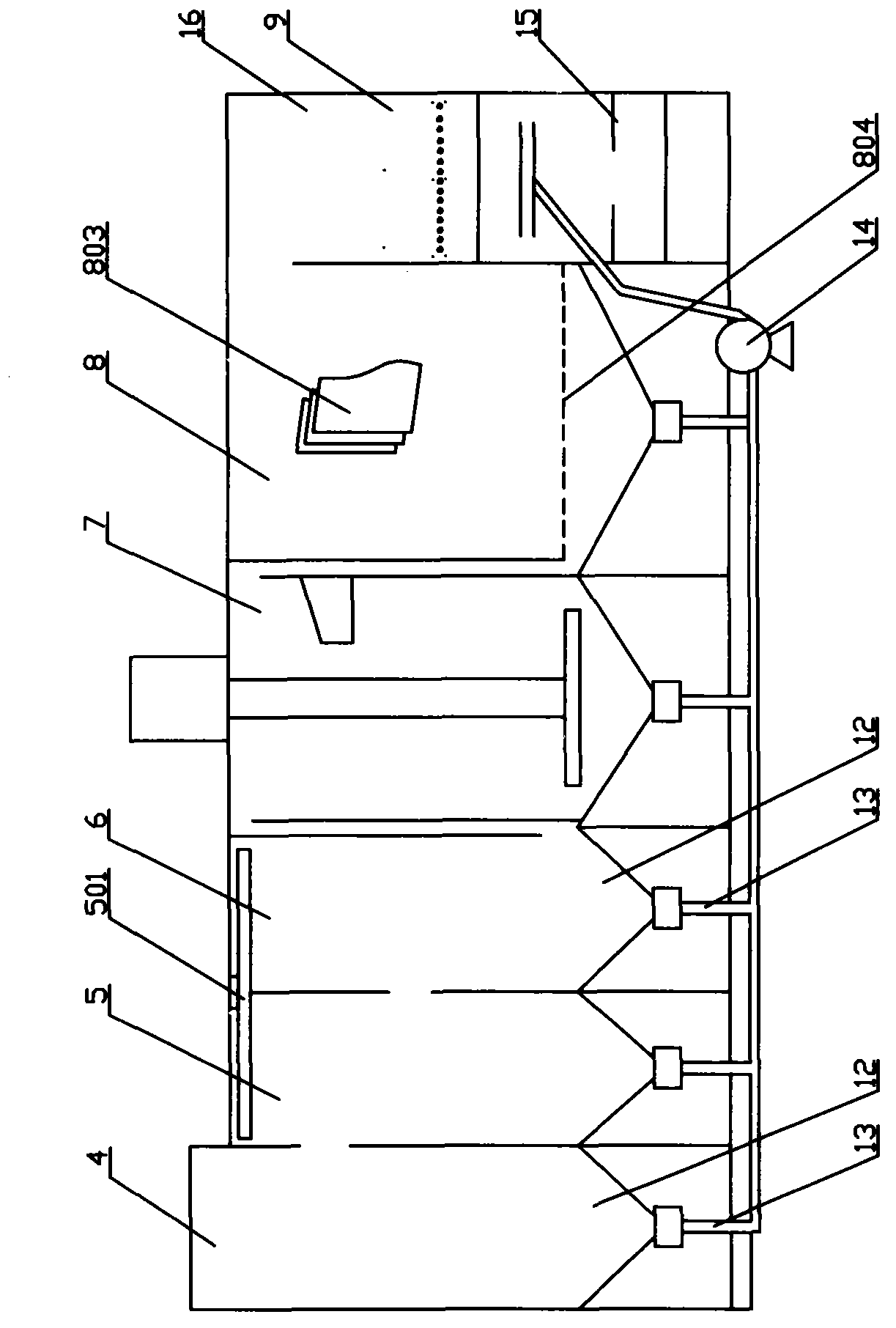

[0008] Depend on figure 1 As shown in the sewage treatment plant, each pool is made into an integral structure, which is easy to manage, easy to operate, and occupies a small area. 3 and the inside of the coagulation tank 4 are octahedral structures, and the water inlets 101 are respectively located above the pool bodies, and the water outlets 102 are respectively located below the pool bodies, and the inside of the mechanical forced solid-liquid separation tank 7 is a cone structure. A variable-speed agitator 701 is installed on its upper part, and the settled water enters the clarification tank 16 for clarification treatment. The bottom of the aerobic tank, anaerobic tank, mechanical forced solid-liquid separation tank and sedimentation tank are all equipped with sludge collection buckets, and a sludge discharge pipe 13 is also installed at the bottom of each sludge collection bucket 12, each sludge discharge The pipe 13 communicates with the sludge thickening tanks 10 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com