Device and method for endurance experiment of automatic gearshift

A technology of automatic shifting and experimental device, applied in the field of vehicle experiment, can solve the problems of extensive test action, lack of automatic shifting mechanism performance, lack of sensor elements, etc., and achieve the effect of powerful logic programming ability and precise control ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

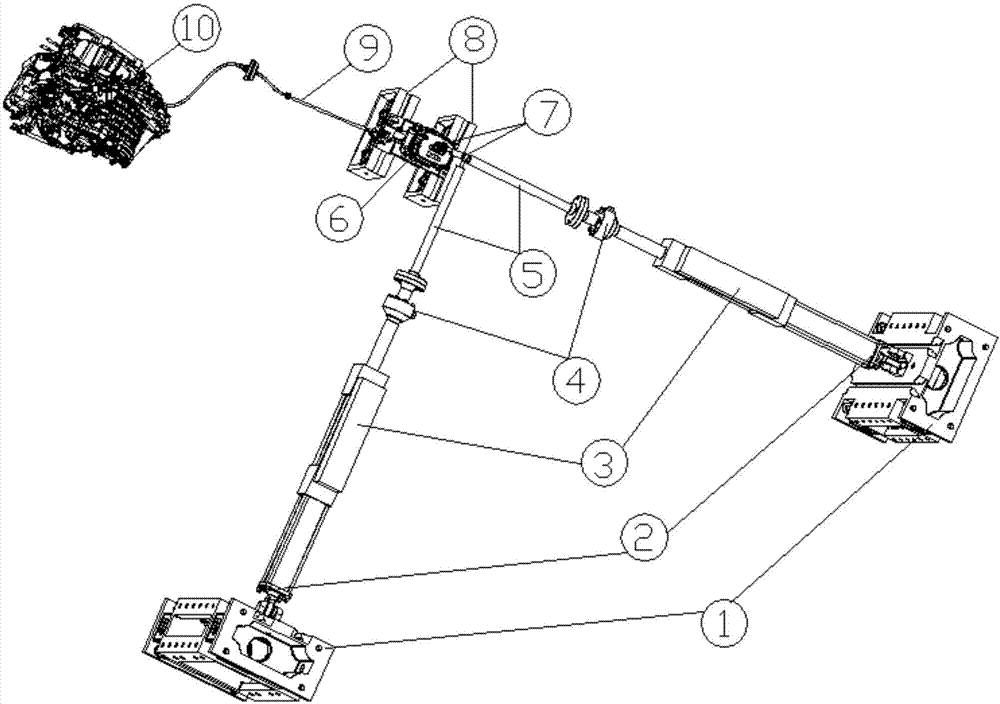

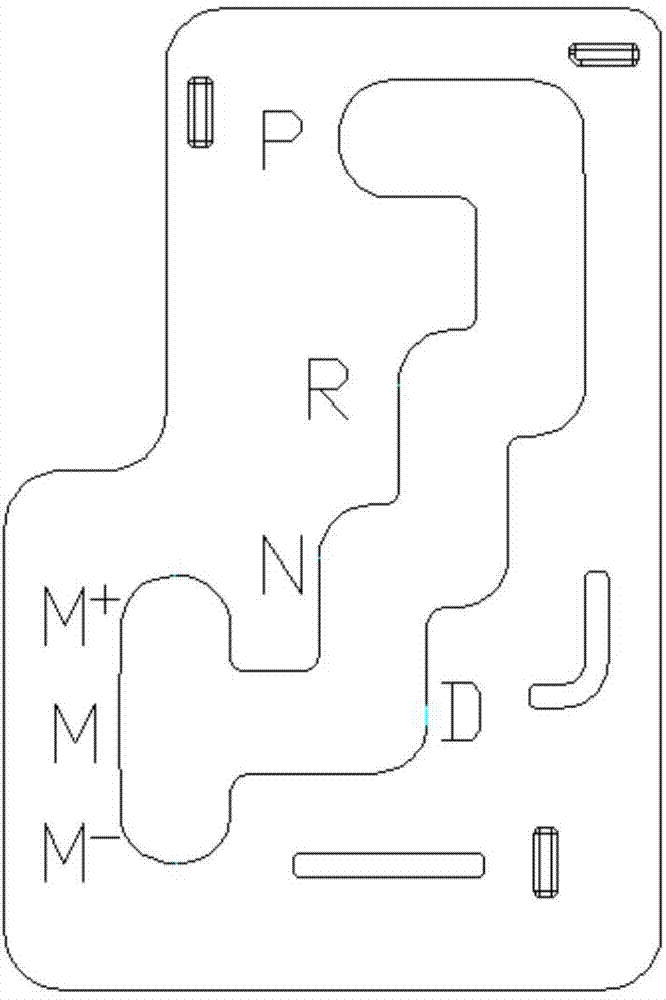

[0020] figure 1 It is a structural schematic diagram of a durability test device for an automatic shift mechanism of the present invention, the automatic shift mechanism assembly 6 is installed on the mounting bracket 8, and the automatic transmission assembly 10 connects with the automatic shift mechanism assembly 6 through the shift cable 9 Connections, also including the gearshift mechanism and control system;

[0021] The shift control mechanism includes a fixed base 1, a hydraulic cylinder assembly 3 installed on the fixed base 1, and a loading rod 5 connected to the hydraulic cylinder. There are two groups of shift control mechanisms. The loading lever 5 is connected with the shift lever of the automatic shift mechanism assembly 6;

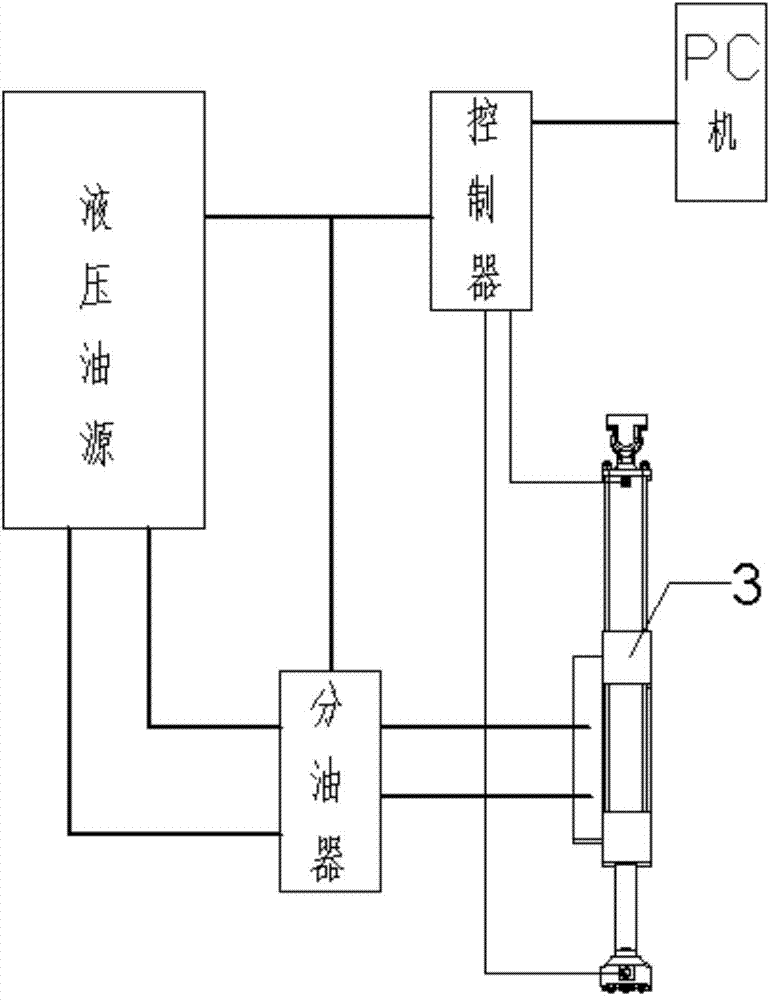

[0022] The control system includes a PC, a controller connected to the PC and a displacement sensor 2 arranged on the hydraulic cylinder assembly 3, such as image 3 As shown, the displacement sensor 2 is connected with the controller to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com