Control system for PTC heater

A control system and heater technology, which is applied in the direction of temperature control using electric methods, can solve problems such as the impact of high-power electrical products, the impact of electrical service life, and the impact of electrical life, to avoid frequent conduction and disconnection actions, Effects of prolonging life, improving service life and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but not limited to these embodiments. The present invention covers any alternatives, modifications, equivalent methods and schemes made on its essence.

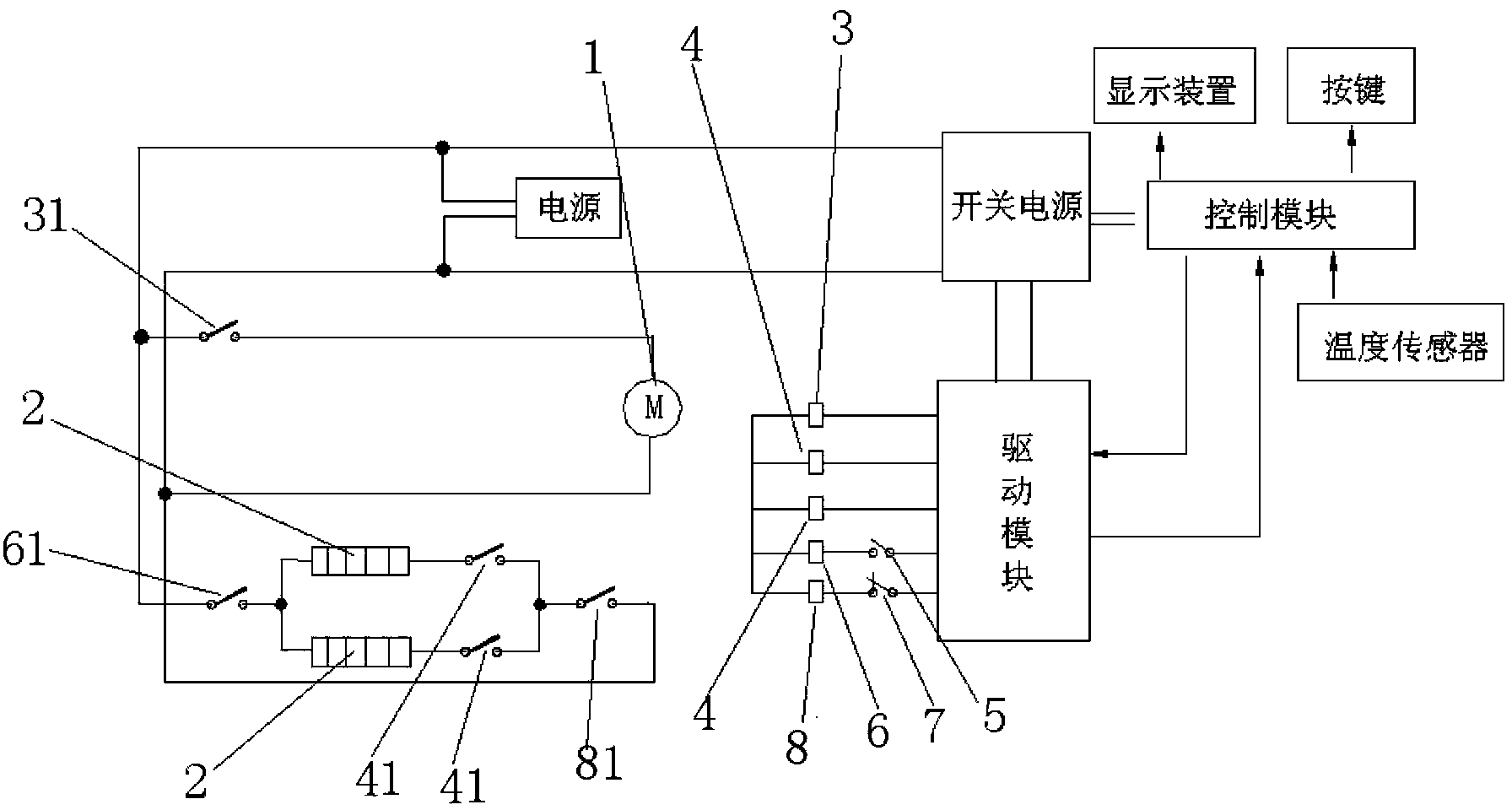

[0022] Such as figure 1 As shown, a PTC heater control system includes a power supply, a switching power supply, a control module, a drive module, a water pump 1 and a heater comprising several groups of PTC heating elements 2, the power supply is connected to the switching power supply, and the switching power supply They are respectively connected with the control module and the drive module, so that the switching power supply converts the power supply voltage into DC low-voltage electricity, which is respectively supplied to the control module and the drive module, and the water pump and several groups of PTC heating elements connected in parallel are parallel Connected to both ends of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com