LED single crystal cup-in-cup support

A cup-in-a-cup, single-crystal technology, applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as rising product defect rate, reducing light usage rate, and prone to virtual soldering, so as to improve reflectivity and utilization rate, It is conducive to market promotion and the effect of increasing the punching area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

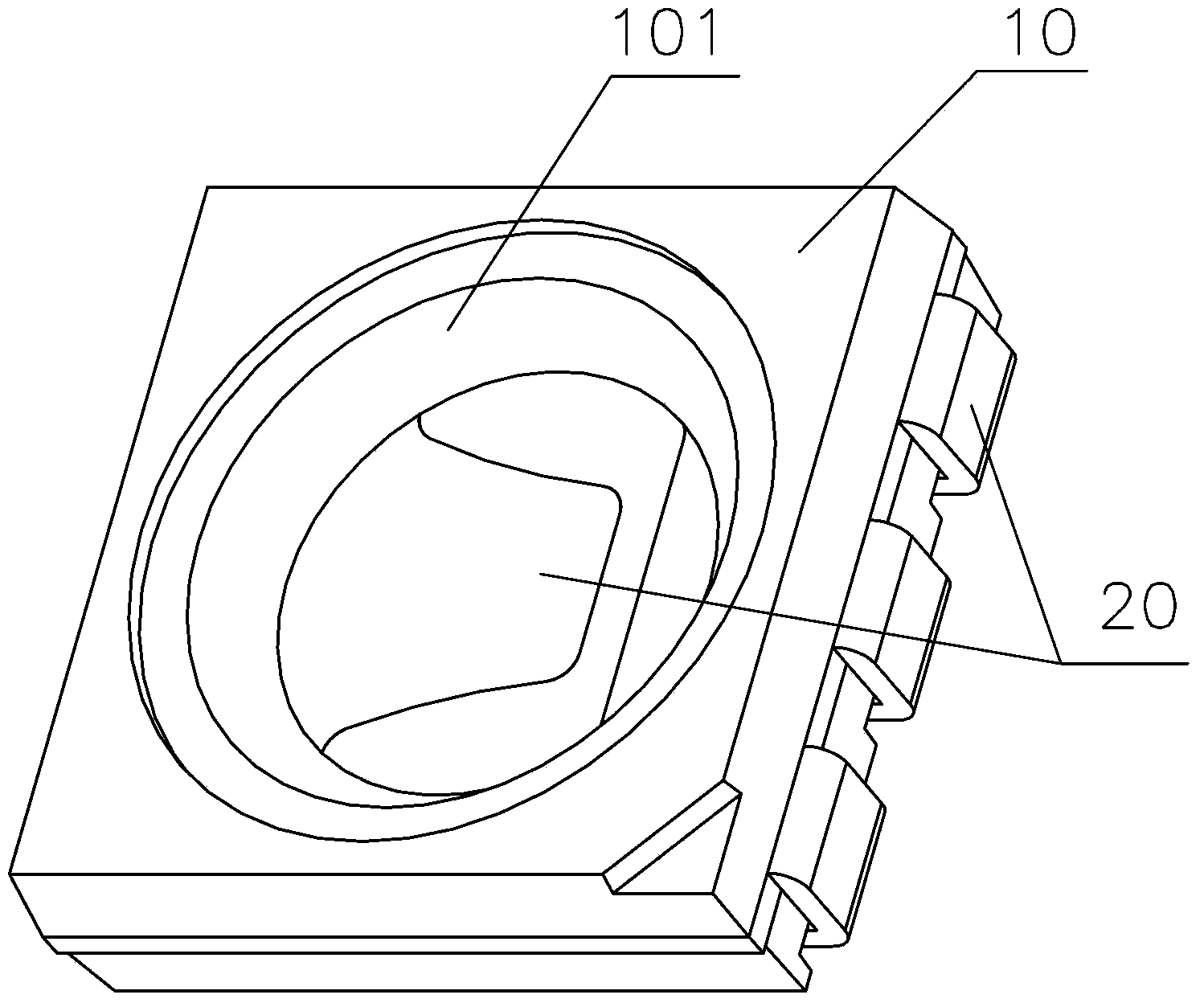

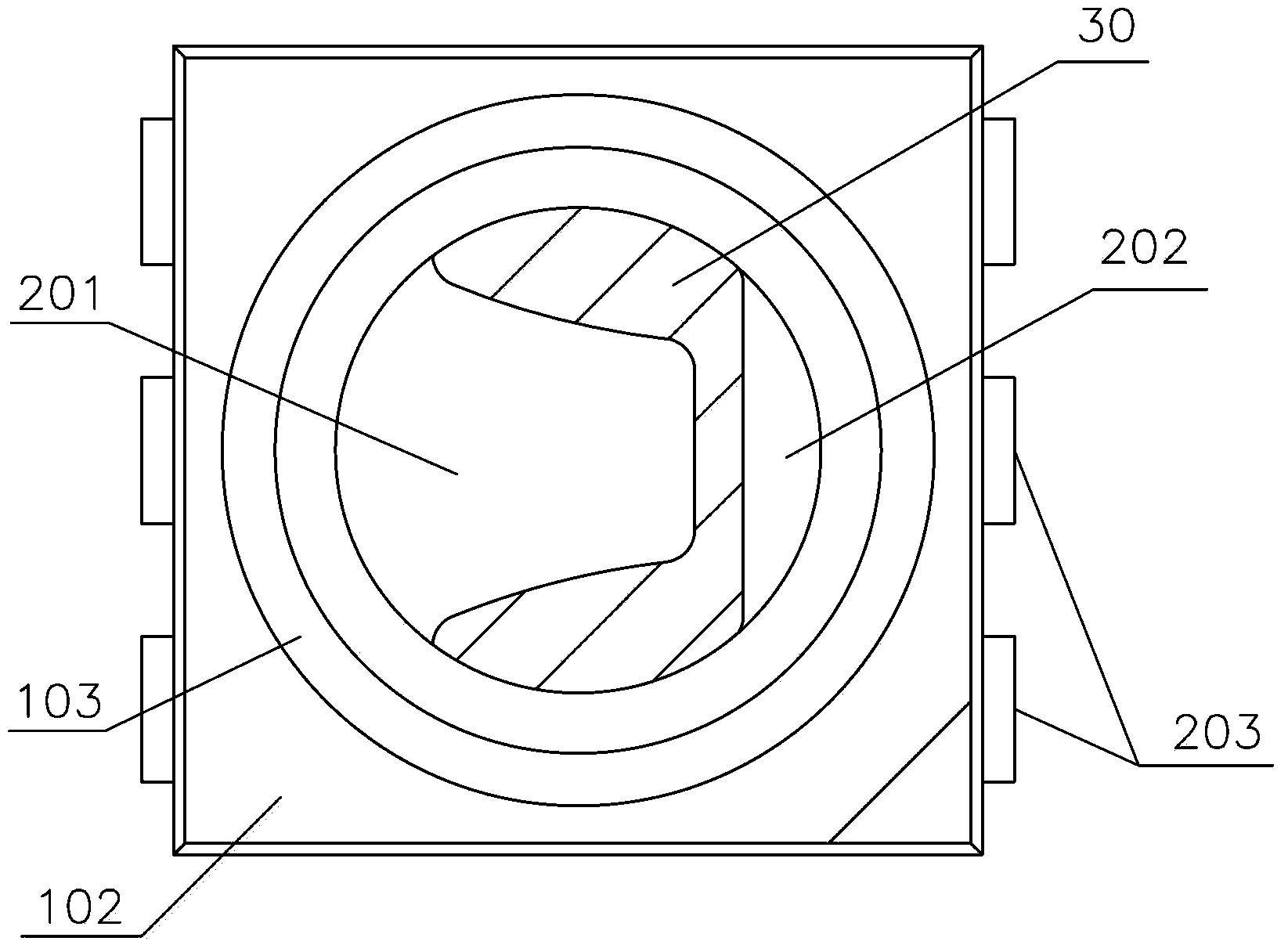

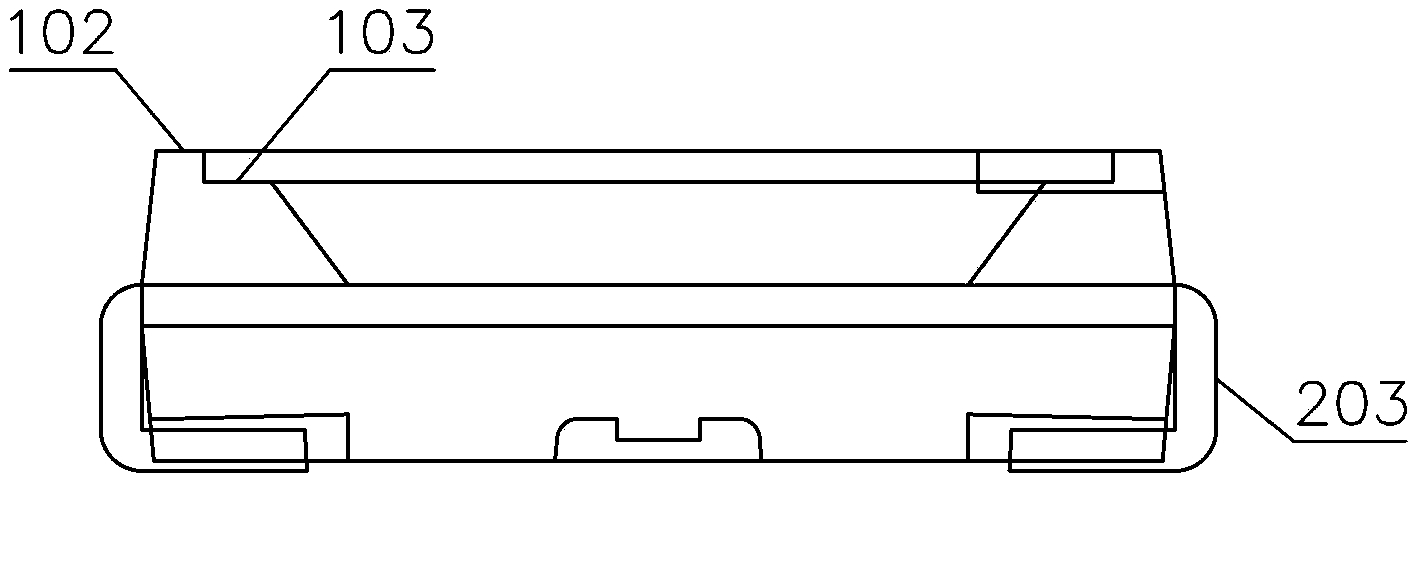

[0018] refer to figure 1 , figure 2 As shown, it is a specific embodiment of a cup holder in an LED single crystal cup disclosed by the present invention. It includes a plastic package 10 and a metal stamping part 20. A groove is formed on the upper surface of the plastic package 10 to form a reflective cup 101. The metal One end of the stamping part 20 is embedded in the plastic package 10. In this embodiment, two metal stamping parts 20 are symmetrically arranged on both sides of the plastic package 10, and one end of the two metal stamping parts 20 embedded in the plastic package 10 is respectively formed. The first pad 201 and the second pad 202 are filled with plastic 30 between the first pad 201 and the second pad 202. The first pad 201 is used to place the LED chip, and the LED chip and the second pad are connected by a gold wire. The two pads...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap