Clamping device for sewing hip pocket cloth of trousers

A technology for clothing and back pockets, which is applied in the field of clamping devices for sewing back pockets of trousers, which can solve problems such as low work efficiency, elongated waist of the back trousers, inconsistent tightness of trouser pocket fabrics, etc., and improve work efficiency , easy to operate and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

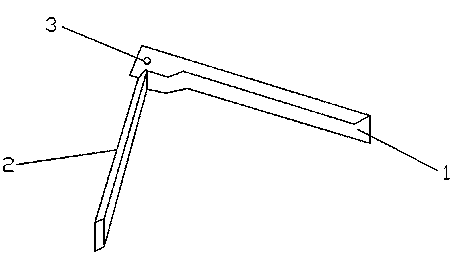

[0010] Such as figure 1 As shown, the clamping device for sewing the back pocket cloth of trousers is characterized in that it includes an L-shaped plate 1 and a rectangular plate 2, and one end of the rectangular plate 2 is movably connected to one end of the L-shaped plate 1; It is connected with the L-shaped plate 1 through the horizontal rotating shaft 3; the length of the rectangular plate 2 is the same as that of the L-shaped plate 1

[0011] The working principle of the present invention is that when the trouser pocket is sewn, the fabric of the trouser pocket is clamped by the L-shaped plate 1 and a rectangular plate 2, and the thickness of the rectangular plate is fixed, so that the fabric of the trouser pocket is folded uniformly Then, fix the folded trouser pocket panel fabric on the back trouser panel fabric for sewing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com