Slicing machine blade disc

A slicing machine and cutter head technology, applied in metal processing and other directions, can solve the problems of material blockage and blade damage, and achieve the effect of saving materials, saving blade materials and simplifying the operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

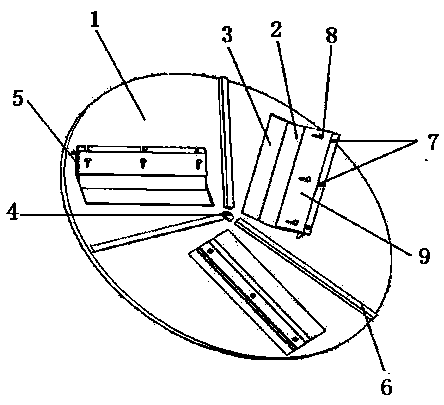

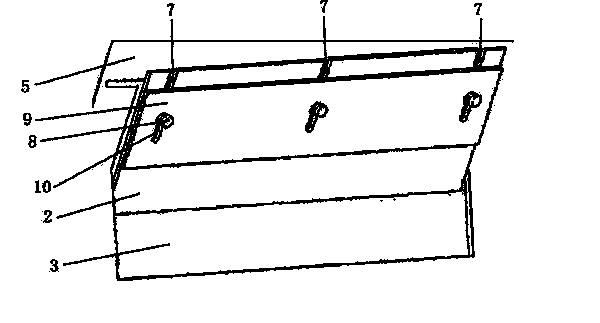

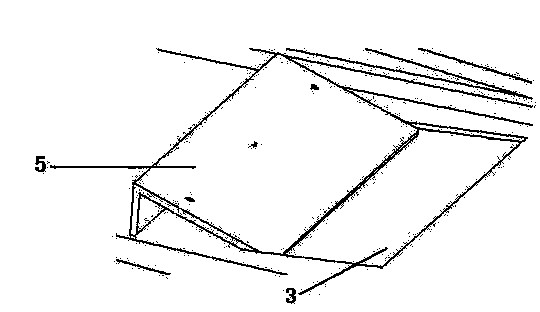

[0033] Such as Figure 1-Figure 3 As shown, the slicer cutter head includes a cutter head body 1, a blade 2, a discharge port 3, a mounting hole 4 and a blade installation slope 5, and the cutter head body 1 is provided with three discharge ports 3; A blade installation slope 5 is installed on the cutterhead main body 1 on one side of each discharge port 3, and each blade installation slope 5 obliquely extends into the discharge port 3; the blade 2 has a blade chute 7, and the blade 2 passes through the The blade chute 7 cooperates with the fixing mechanism 8 and is installed on the blade installation slope 5 , and the blade 2 can adjust its position on the blade installation slope 5 through the blade chute 7 . The thickness of the section can be adjusted only by moving the adjusting blade 2 parallel to the blade installation slope 5 . During use, it must be ensured that the blade edge of the blade 2 extends below the discharge port 3, so as to ensure that the blade fully con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com