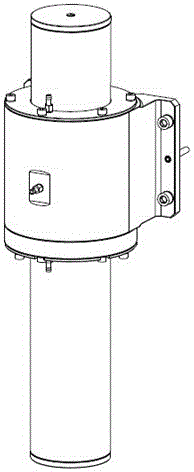

An ultra-precise aerostatic weight traction device

A technology of air static pressure and traction device, which is applied in the direction of lifting device and hoisting device to achieve the effect of ensuring accuracy and precise circumferential positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

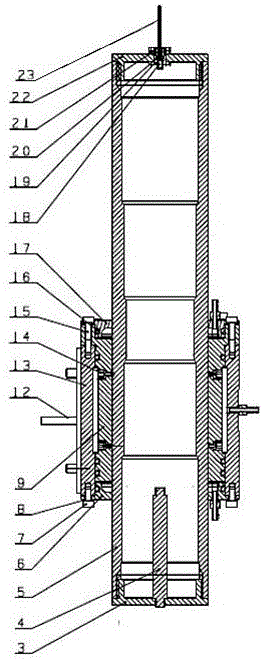

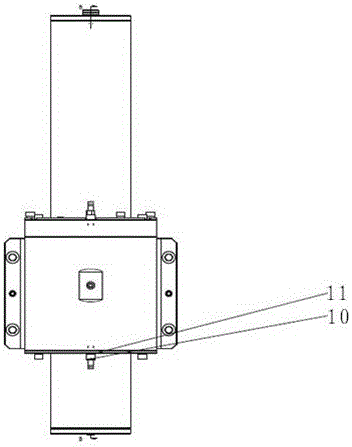

[0020] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0021] refer to figure 1 , Figure 4 As shown, after the traction steel wire 23 is fixedly connected with the steel ball 20, the steel ball 20 is put into the steel ball positioning sleeve 19, and after adjusting the contact angle and contact position between the steel ball 20 and the steel ball positioning sleeve 19, the steel ball lock The tightening screw 18 fixes the location and locking of the traction steel wire fixing steel ball 20.

[0022] The steel ball positioning sleeve 19 is coaxially positioned and installed with the weight connecting cover 22, and is pressed and locked by the locking nut 21.

[0023] The weight connection cover 22 is connected with one end of the weight 5 , and is connected with the other end of the weight 5 after the counterweight rod 4 is fixed on the counterweight end cover 3 .

[0024] The restr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com