Hidden access door with metal rotating shafts

A technology for hardware shafts and inspection doors, which is applied to door leaves, windows/doors, door/window accessories, etc. It can solve problems such as damage to the corners of the inspection door trim panels, inability to disassemble, and difficulty in smooth docking, etc., to increase the maintenance space, The effect of avoiding material waste and improving aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

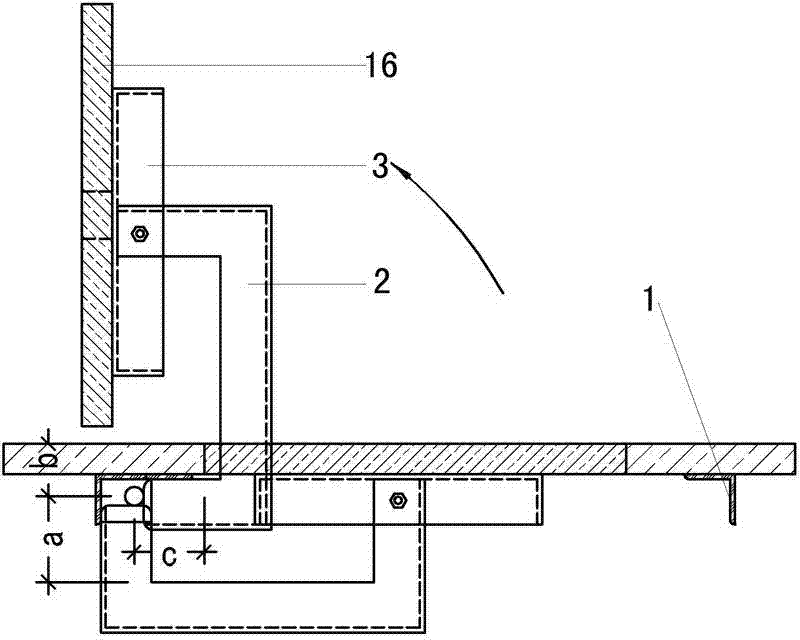

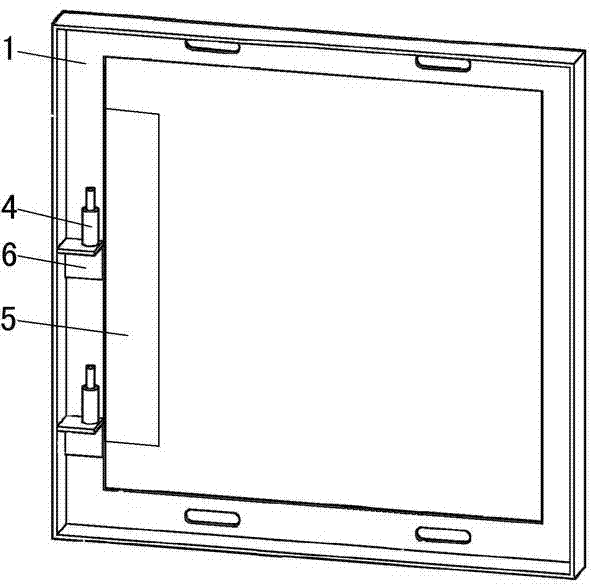

[0026] Example: such as figure 1 As shown, a hidden hardware rotating shaft inspection door includes an outer ring 1 , a moment arm 2 and an inner ring 3 .

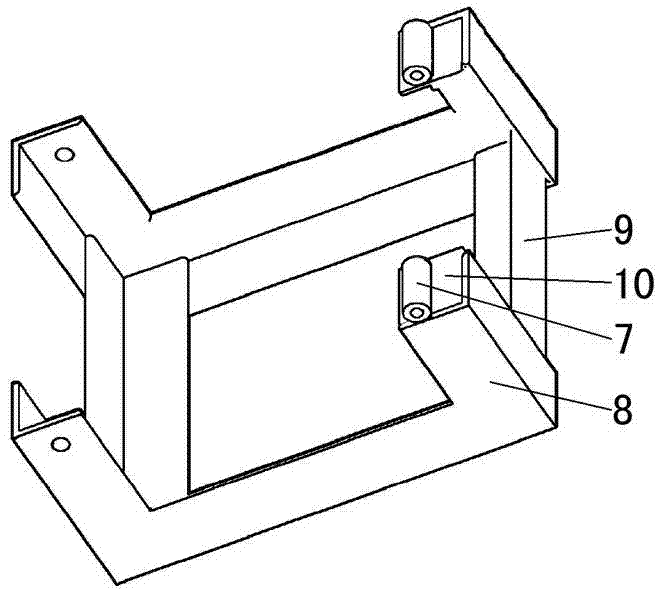

[0027] like figure 2 , Figure 5 , Image 6 , Figure 7 Shown, outer ring 1 is made up of angle steel ring, oblong hole, rotating shaft 4, angle steel 2 6, limit flat iron 5. The outer ring 1 is an angle steel ring welded by angle steel, one side is welded with a shaft 4, and the shaft 4 is arranged inside the angle steel ring, and the upper and lower sides are provided with oblong holes, and the outer ring 1 is welded with an angle steel 6, through which the shaft 4 is fixed. Angle steel two 6 fix the rotating shaft 4, keep the central axis of the rotating shaft 4 and the central axis of the rotating shaft accessories 7 in the same straight line, and perpendicular to the ground. The outer ring 1 is provided with a limit flat iron 5 on one side of the welding shaft 4, and the thickness of the limit flat iron 5 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com