Separated finger buffering diaphragm spring of shock absorber

A diaphragm spring and separation finger technology, applied in the field of clutches, can solve the problems of lack of elasticity, low strength of spring diaphragm, rigid wear of components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

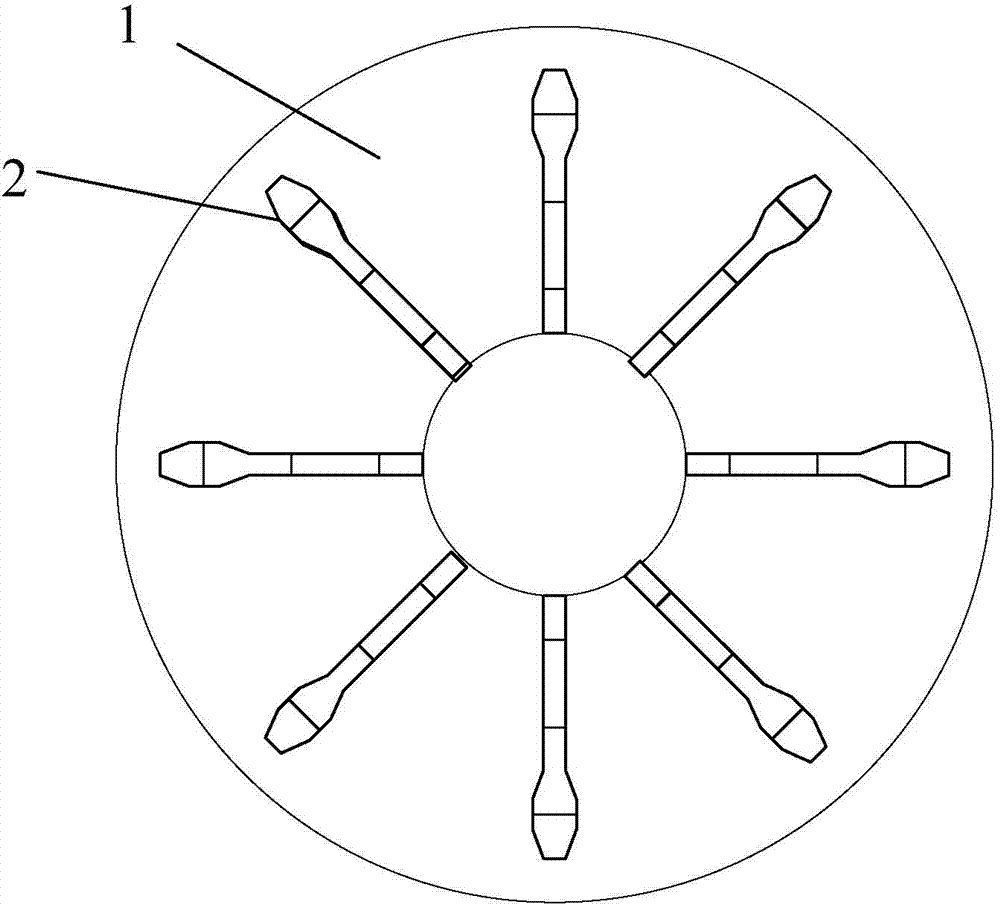

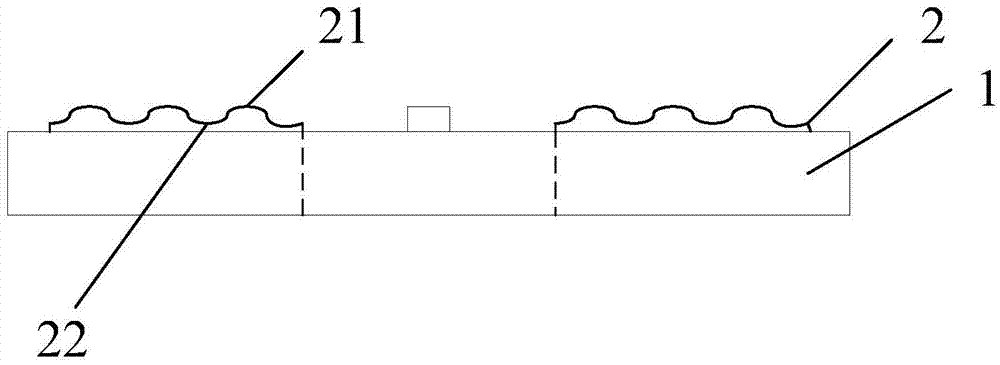

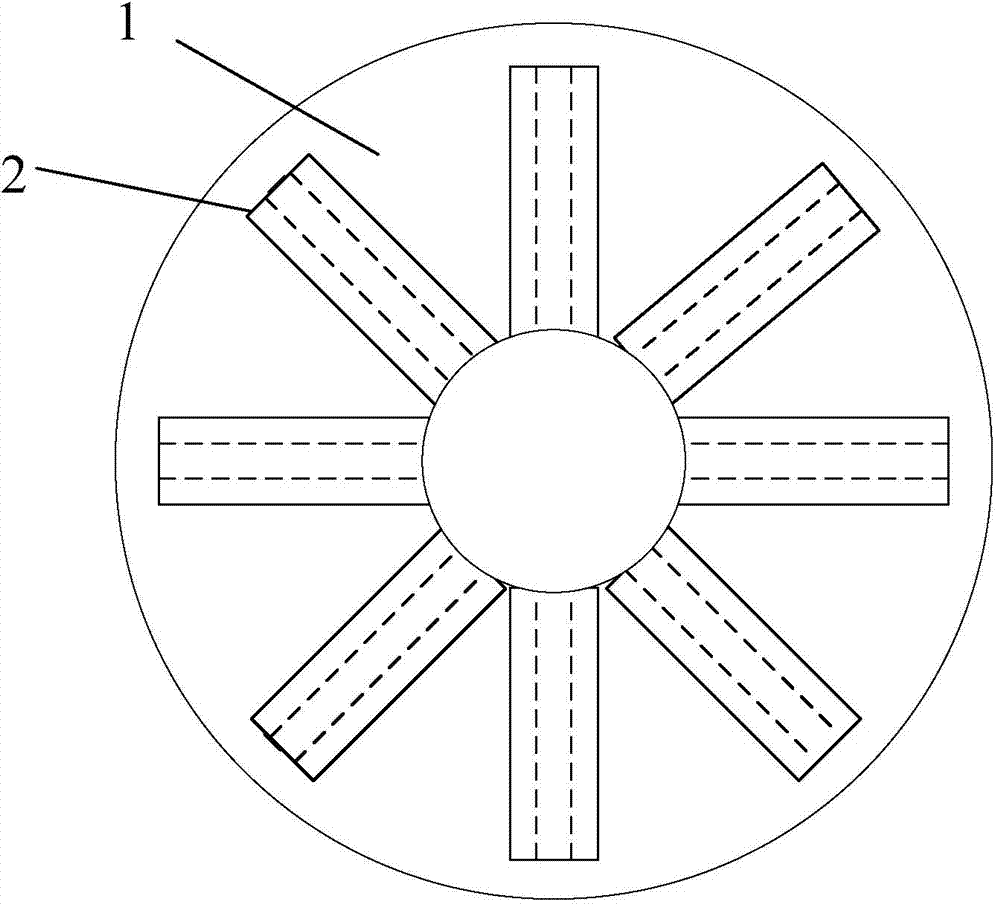

[0017] Such as Figure 1 to Figure 4 as shown, figure 1 and figure 2 It is a top view and a side view of a shock absorber separation finger buffer diaphragm spring in Embodiment 1 of the present invention, image 3 and Figure 4 It is a plan view and a side view of a shock absorber separation finger buffer diaphragm spring in Embodiment 2 of the present invention.

[0018] refer to Figure 1 to Figure 4 , the embodiment of the present invention provides a shock absorber separation finger buffer diaphragm spring, including: a diaphragm spring body 1 and a plurality of separation fingers 2; the spring body 1 is circular, and a plurality of separation fingers 2 are distributed on the diaphragm On the inner ring of the spring main body 1, for example 4, 8 or more.

[0019] refer to figure 1 and figure 2 , in Embodiment 1 of the present invention, each separating finger 2 has a plurality of sequentially connected crests 21 and troughs 22 along the radial direction to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com