Total station tripod antiskid locking device

A technology for locking devices and tripods, which is applied in the direction of machines/brackets, supporting machines, mechanical equipment, etc., can solve the problems of easy sliding of total station tripods, and achieve the effects of avoiding micro-slipping of instruments, saving working time, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

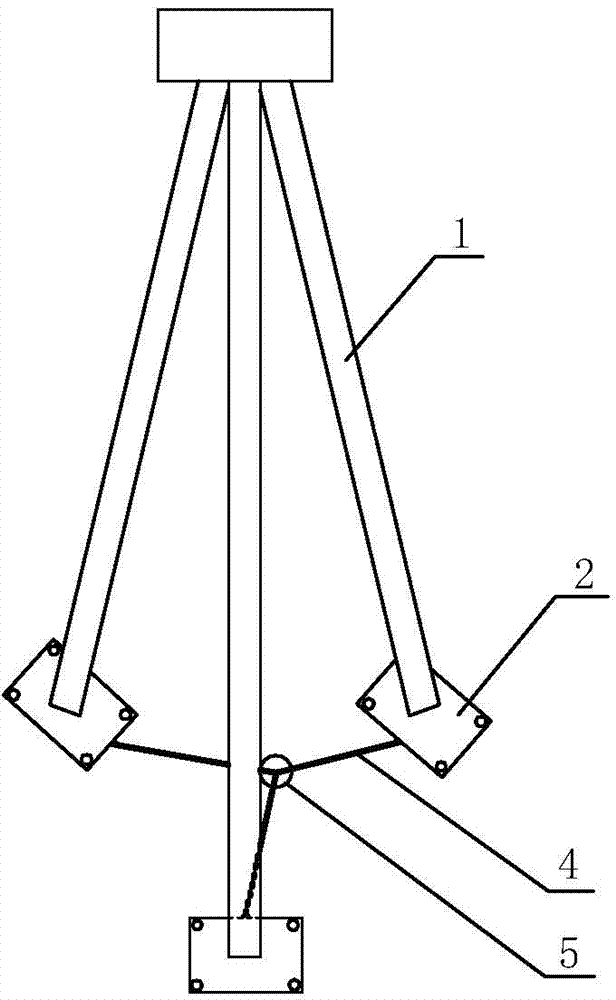

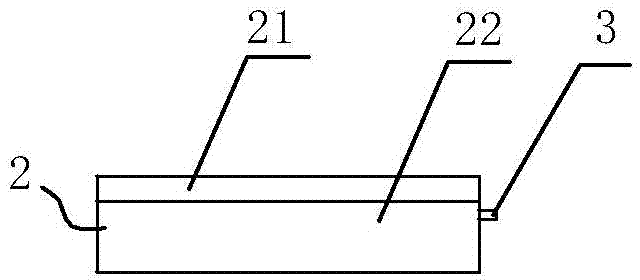

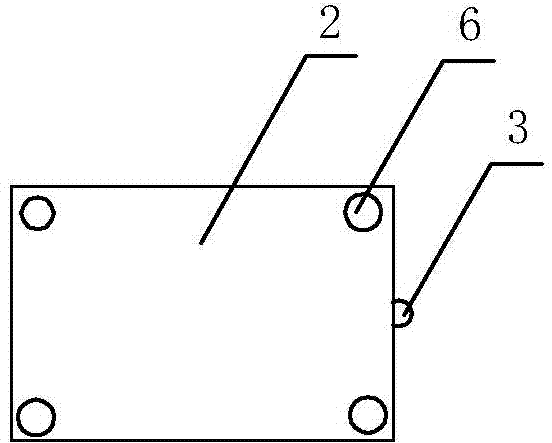

[0024] Example 1: An anti-skid locking device for the tripod of a total station, such as figure 1 As shown, the tripod 1 is included. The tip of the tripod foot is provided with a non-slip foot pad 2. The non-slip foot pad is mainly composed of an upper locking layer 21 and a lower friction layer 22. The bottom surface of the lower friction layer is provided with anti-skid patterns, and the bottom of the lower friction layer The solid layer and the lower friction layer are connected by pins 6 (see Figure 2-Figure 3 ). The upper locking layer of the anti-slip foot pad mainly allows the tip of the tripod to be inserted into it to lock, and the lower friction layer mainly ensures that the foot pad does not slide through the friction between the bottom surface and the ground to achieve the anti-skid effect of the total station tripod. The said non-slip foot pads are set as three separate small non-slip foot pads. The plane size of each small non-slip foot pad is 100×100mm, the uppe...

Embodiment 2

[0027] Embodiment 2: An anti-skid locking device for a total station tripod, comprising a tripod 1, the tip of the tripod foot is provided with an anti-skid foot pad 2, and the anti-skid foot pad is mainly composed of an upper locking layer 21 and a lower friction layer 22 , The bottom surface of the lower friction layer is provided with anti-slip patterns, the upper locking layer and the lower friction layer are connected by pins 6. The anti-slip foot pad is set as a large anti-slip foot pad with an integral structure, and the three toes of the tripod are all installed on the big anti-slip foot Mat (such as Figure 5 Shown). The stability of this structure is greater; but it has high requirements for the flatness of the ground (affecting the leveling operation and accuracy of the instrument), and also affects the activities of the test personnel (affecting standing, easy to touch). This structure does not require additional foot and leg locking and stopping structures.

[0028...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com