Photosensitive drum connection component

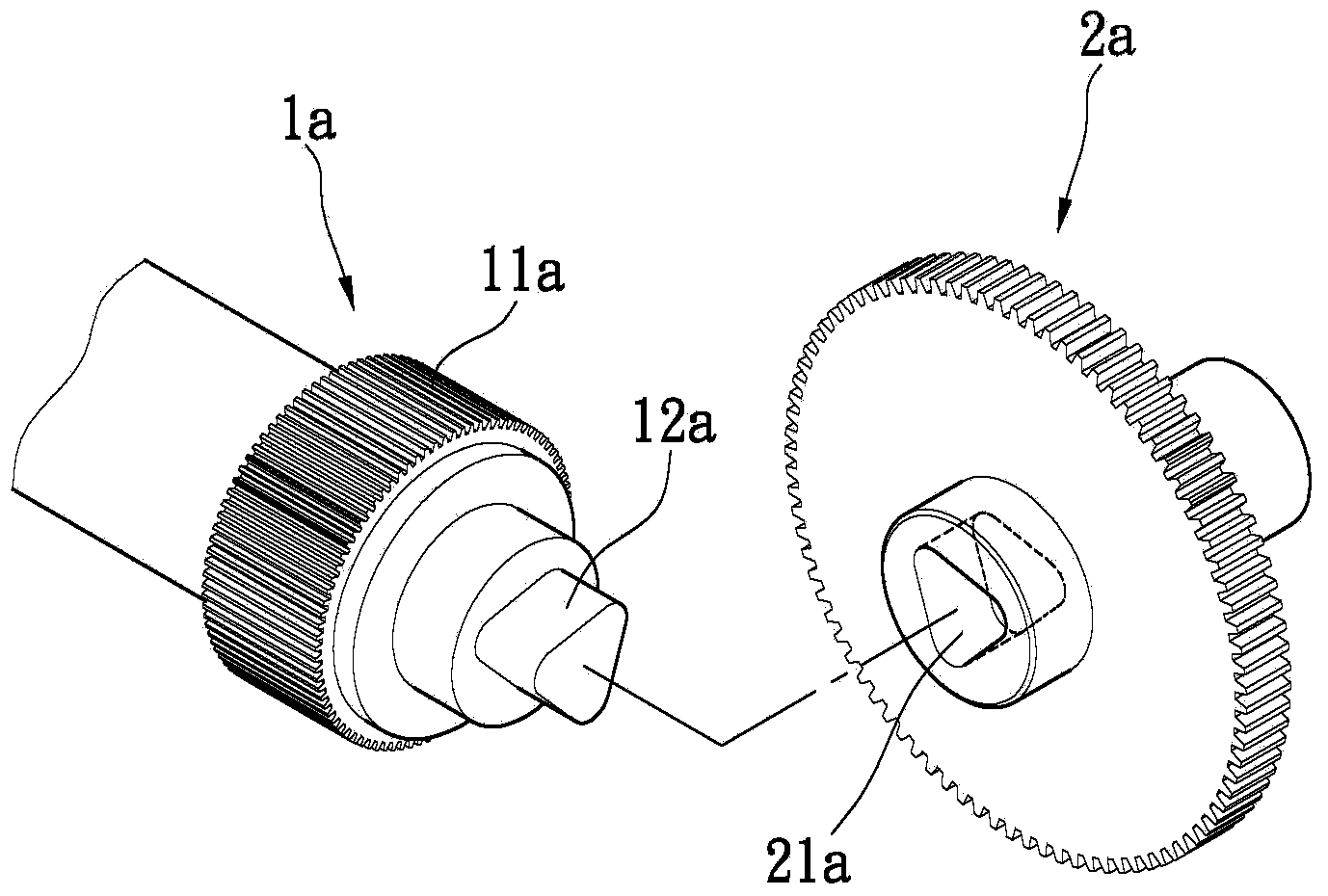

A technology for connecting components and photosensitive drums, used in optics, electrography, instruments, etc., can solve problems such as damage to the drum gear 11a or the triangular column-shaped bumps 12a, and save maintenance expenses, reduce waste, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

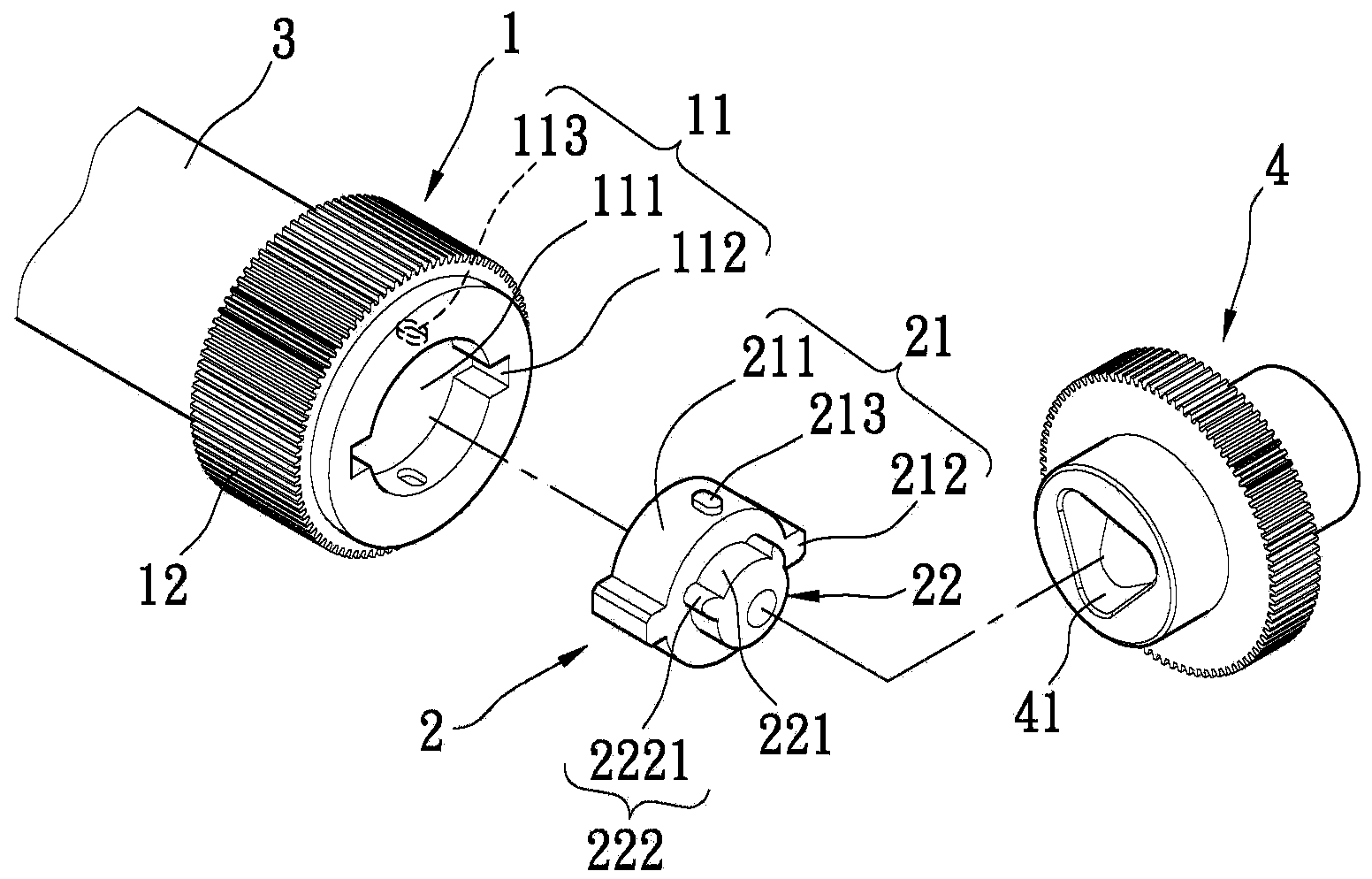

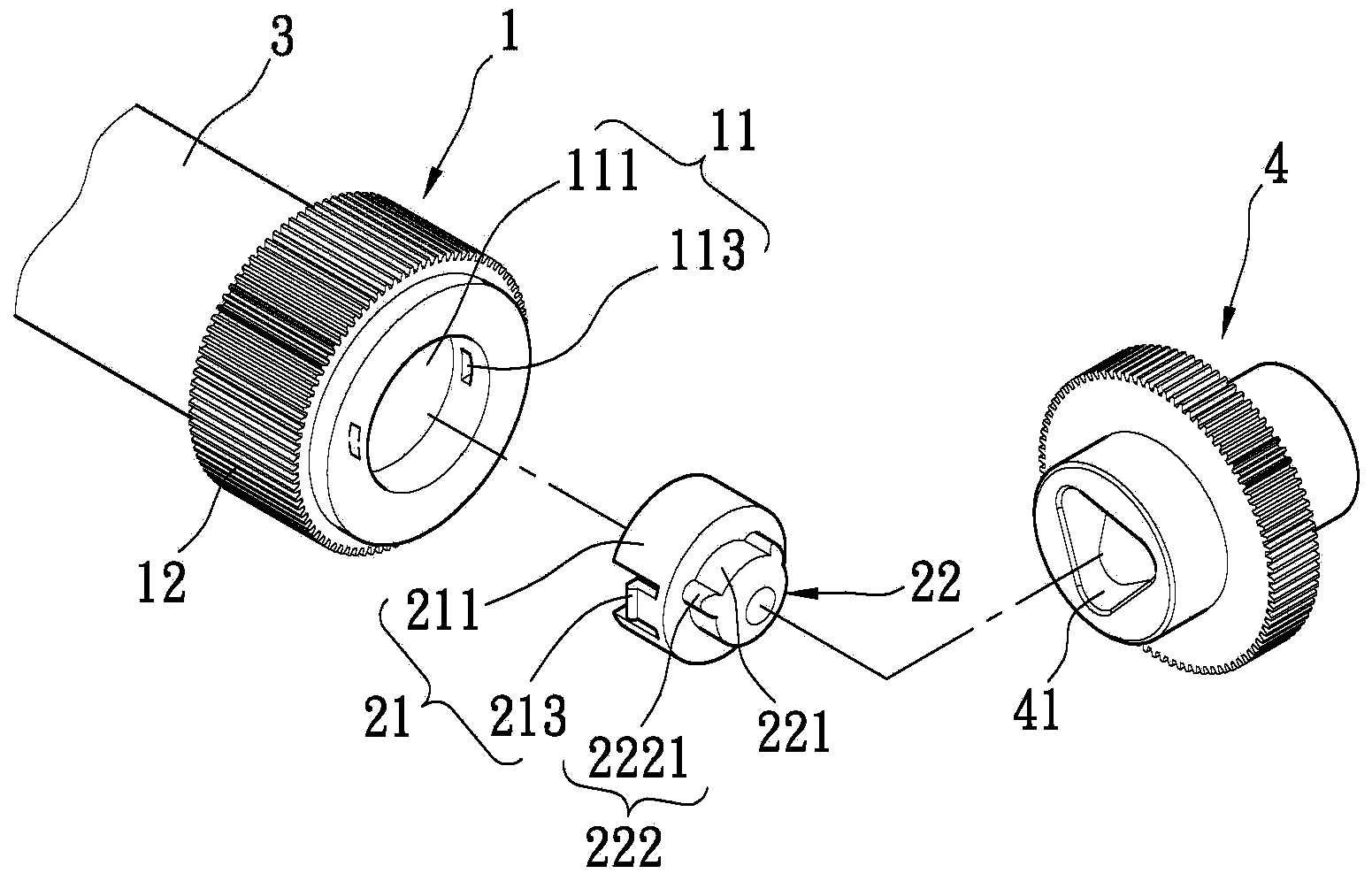

[0057] see Figure 2 to Figure 4 , which is the first embodiment of the present invention, the present invention is a photosensitive drum connection assembly, including: a drum gear 1 and a connector 2 detachably connected to one end of the drum gear 1, the other end of the drum gear 1 is connected to On a photosensitive drum 3 , the connector 2 is connected to a drive shaft 4 . Wherein, the drum gear 1 is detachably connected to the photosensitive drum 3 , or the drum gear 1 and the photosensitive drum 3 are integrally formed.

[0058] The drum gear 1 has a first connecting portion 11 and a ring gear 12 connected to the first connecting portion 11 . The first connecting part 11 is arranged on one end of the drum gear 1, and the first connecting part 11 has a groove 111, and the groove 111 is formed by inwardly recessing one end of the first connecting part 11; the ring gear 12 is arranged on the drum On the other end of the gear 1 , the ring gear 12 is sheathed and fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com