Intelligent surface scanning method for tubular component in reactor pressure container of nuclear power plant

A technology for nuclear power plant reactors and pressure vessels, which is applied in nuclear reactor monitoring, reactors, nuclear power generation, etc., and can solve problems such as danger and exposure of inspectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

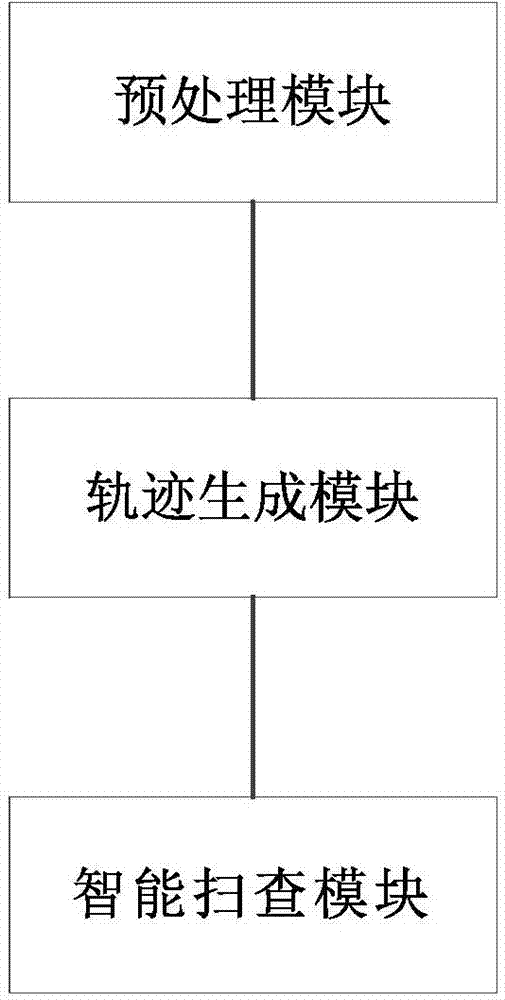

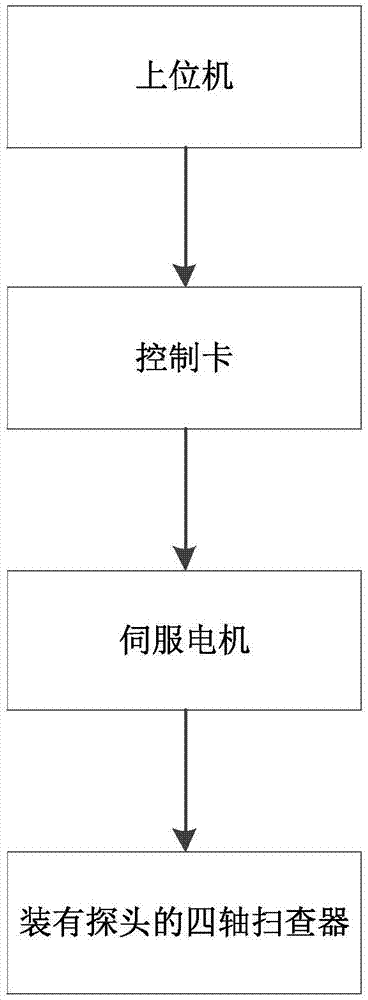

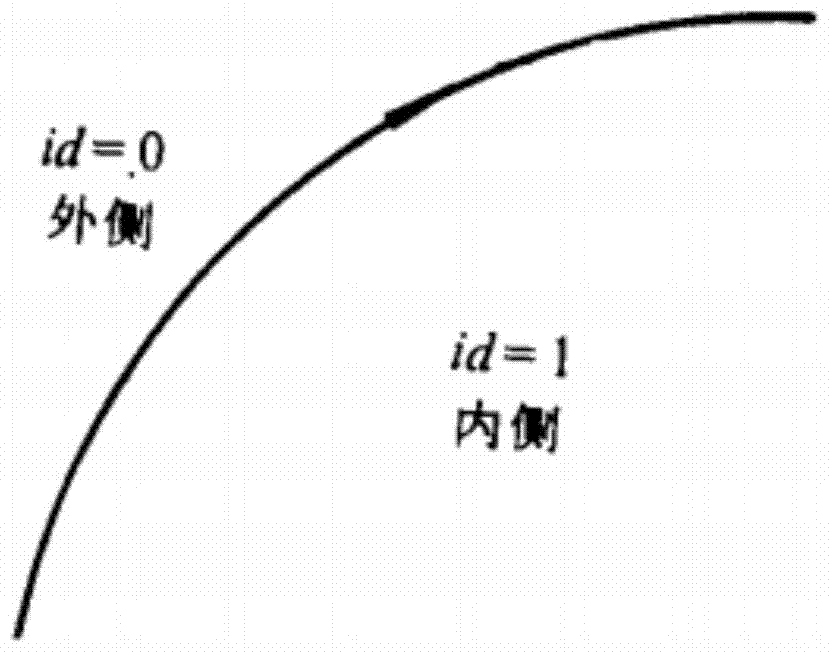

[0079] Such as figure 1 As shown, the intelligent scanning system for the surface of tubular parts in the reactor pressure vessel of a nuclear power plant includes a four-axis scanner for non-destructive testing of the reactor pressure vessel to be installed in the reactor pressure vessel to be tested according to the predetermined installation position, and determine four The 4-degree-of-freedom motion axis of the axis scanner and the spatial position of the probe for non-destructive testing on the corresponding motion axis and the preprocessing module for determining the contour of the tubular component to be detected and the position of the tubular component in the reactor pressure vessel of the nuclear power plant; The motion trajectory generation module for generating the motion trajectory of the probe on the 4 motion axes for intelligent scanning by the contour and spatial position of the tubular parts in the reactor pressure vessel of the nuclear power plant; it is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com