Fixture for replacing strain insulator string

A technology of tension insulators and fixtures, which is applied in the direction of overhead lines/cable equipment, etc., and can solve problems such as insulator insulation failure and insulation impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

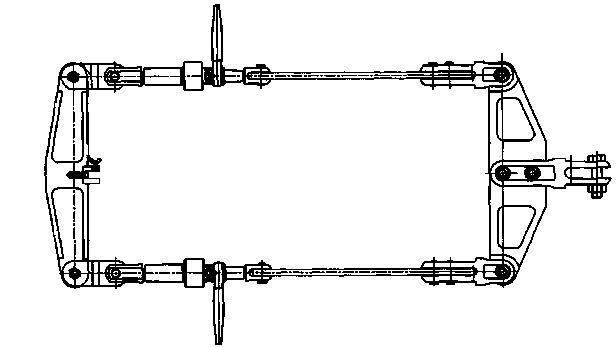

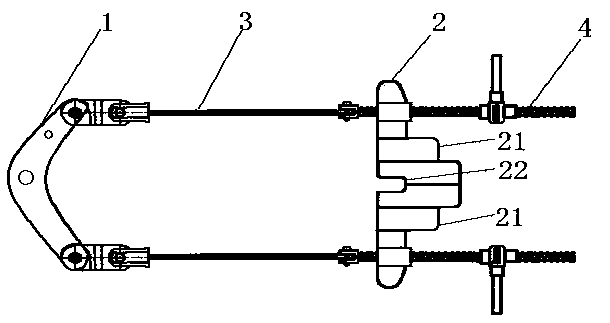

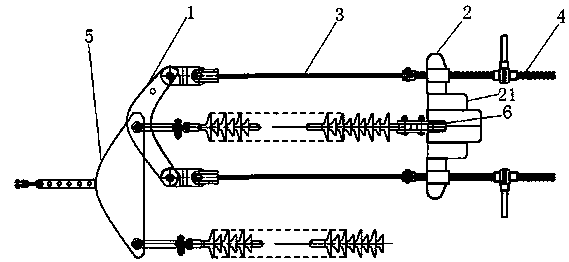

[0018] as attached figure 2 As shown, this embodiment replaces the clamps for the side strings of strain insulators, including the cross-arm side clamp 1, the conductor side clamp 2, and the insulation connection device connecting the cross-arm side clamp 1 and the conductor side clamp 2, for A tightening device for tightening the relative distance between the cross-arm side fixture 1 and the wire side fixture 2. The cross-arm side fixture 1 is an integral component, and the cavity in the middle of the cross-arm side fixture 1 and the cross-arm side fitting The two ends of the connecting plate 5 are matched, and the wire side fixture 2 is composed of two front and rear sub-fixtures 21, and the front and rear two sub-fixtures 21 are detachably connected. There is a through groove 22 extending along the length direction of the joint surface. The through groove 22 on the sub-fixture can be snapped into the three-eye fitting plate 6 for hanging the wire after the two-point fixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com