Anti-twist device

A twist-stop and roller technology, applied in the field of twist-stop devices, to achieve the effect of simple and fast replaceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

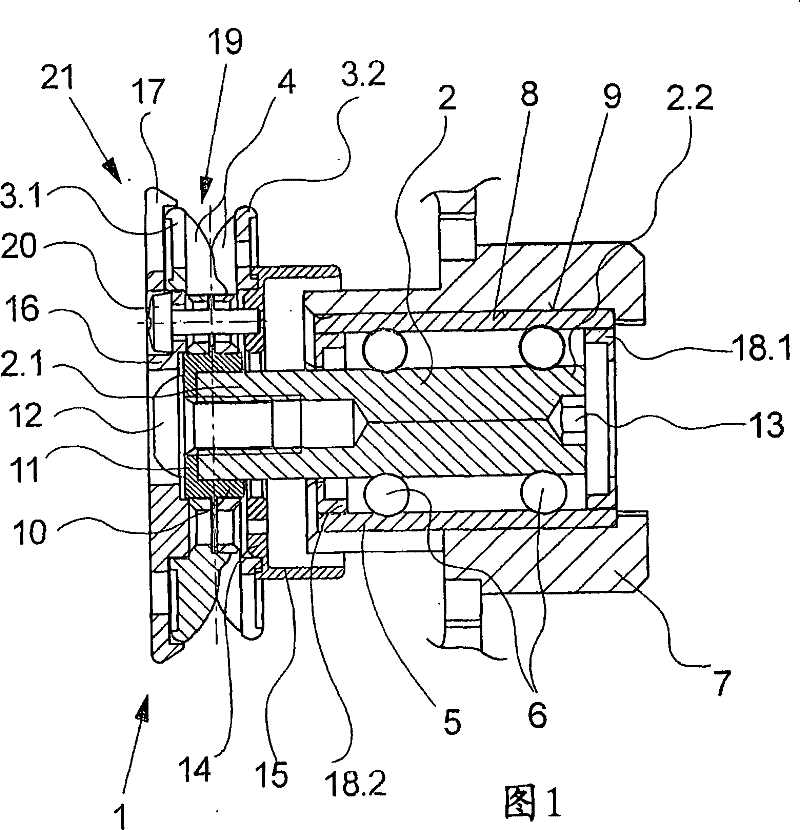

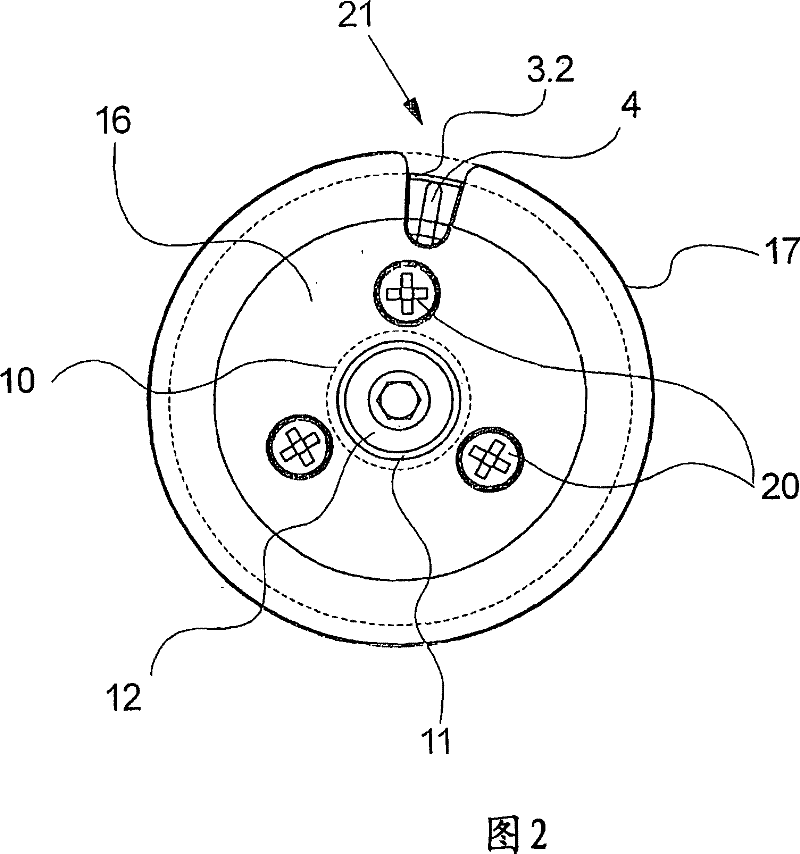

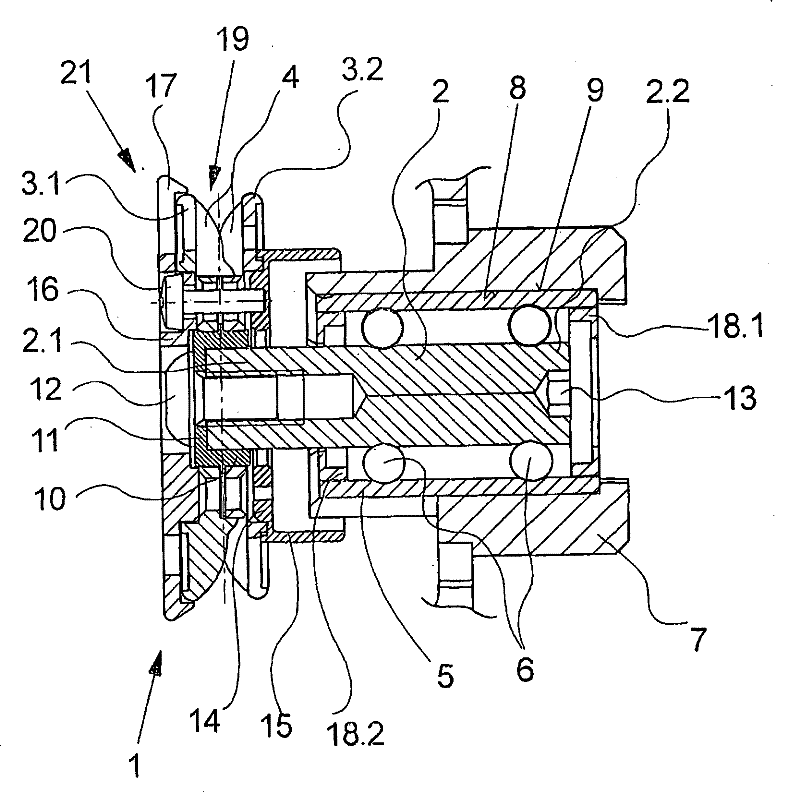

[0023] figure 1 A simplified cross-sectional view of an embodiment of the anti-twist device of the present invention is shown in FIG. figure 2 A side view of this embodiment is shown. As long as one figure is not specifically mentioned, the following description applies equally to both figures.

[0024] The anti-twist device has a shaft 2 . The shaft 2 projects with a bearing end 2.2 into a bearing sleeve 5 . A plurality of rolling bodies 6 are arranged in the bearing sleeve 5 between the circumference of the shaft 2 and the bearing sleeve 5 . The bearing sleeve 5 has a cover 18.1 and 18.2 on each of its end faces. The cover 18 . 2 is annular and extends between the inner diameter of the bearing sleeve 5 and the circumference of the shaft 2 . The shaft 2 protrudes beyond the bearing sleeve 5 with a retaining end 2.1. The anti-twist roller 1 is supported on the circumference of the shaft 2 at the retaining end 2.1. The anti-twist roller 1 has two ceramic discs 3.1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com