Clutch assembly with sensor unit and drive assembly with such clutch assembly

A technology of clutch components and drivers, applied in the direction of clutches, magnetic drive clutches, non-mechanical drive clutches, etc., can solve the problems of difficult maintenance, difficult assembly of sensors, etc., and achieve the effect of simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

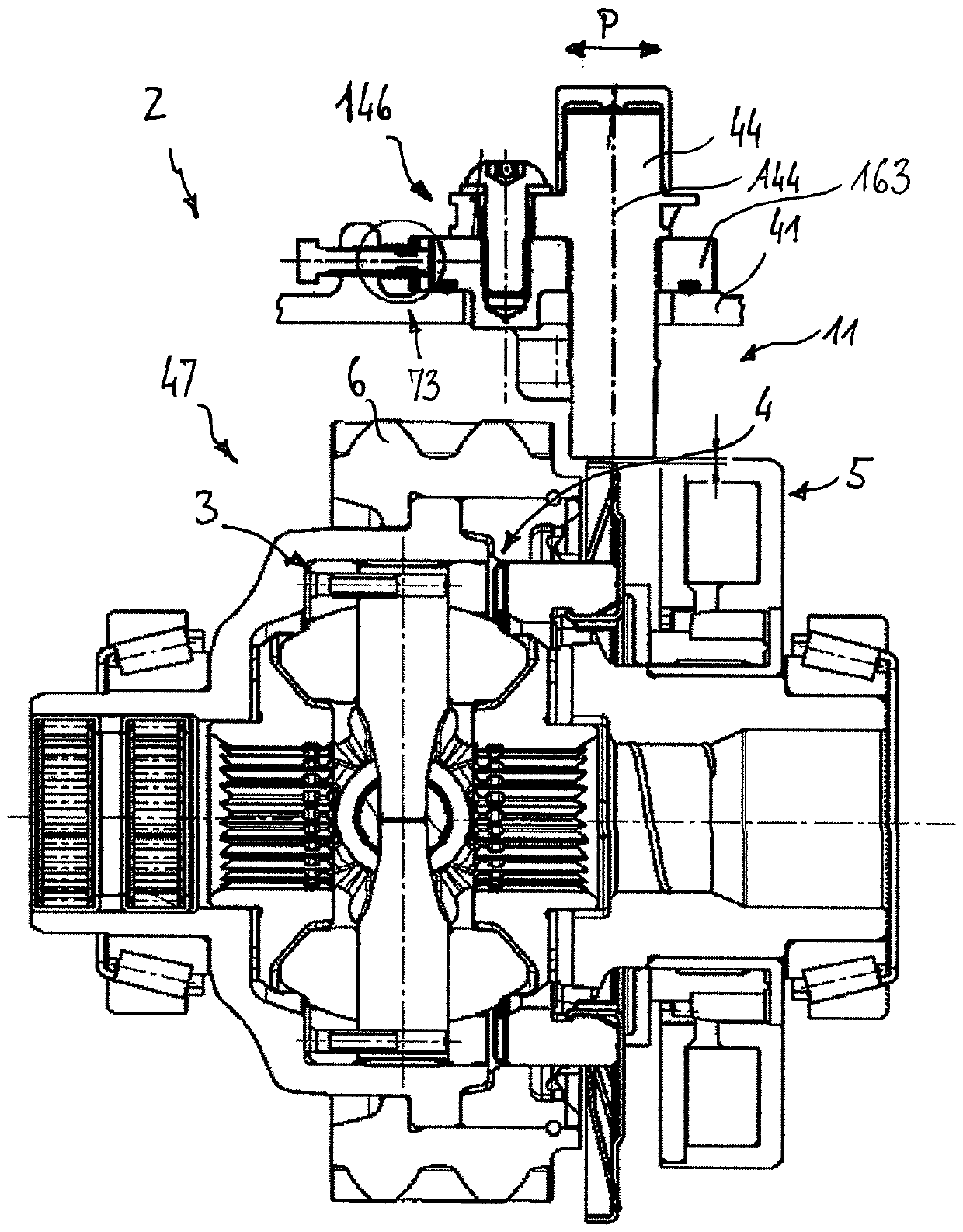

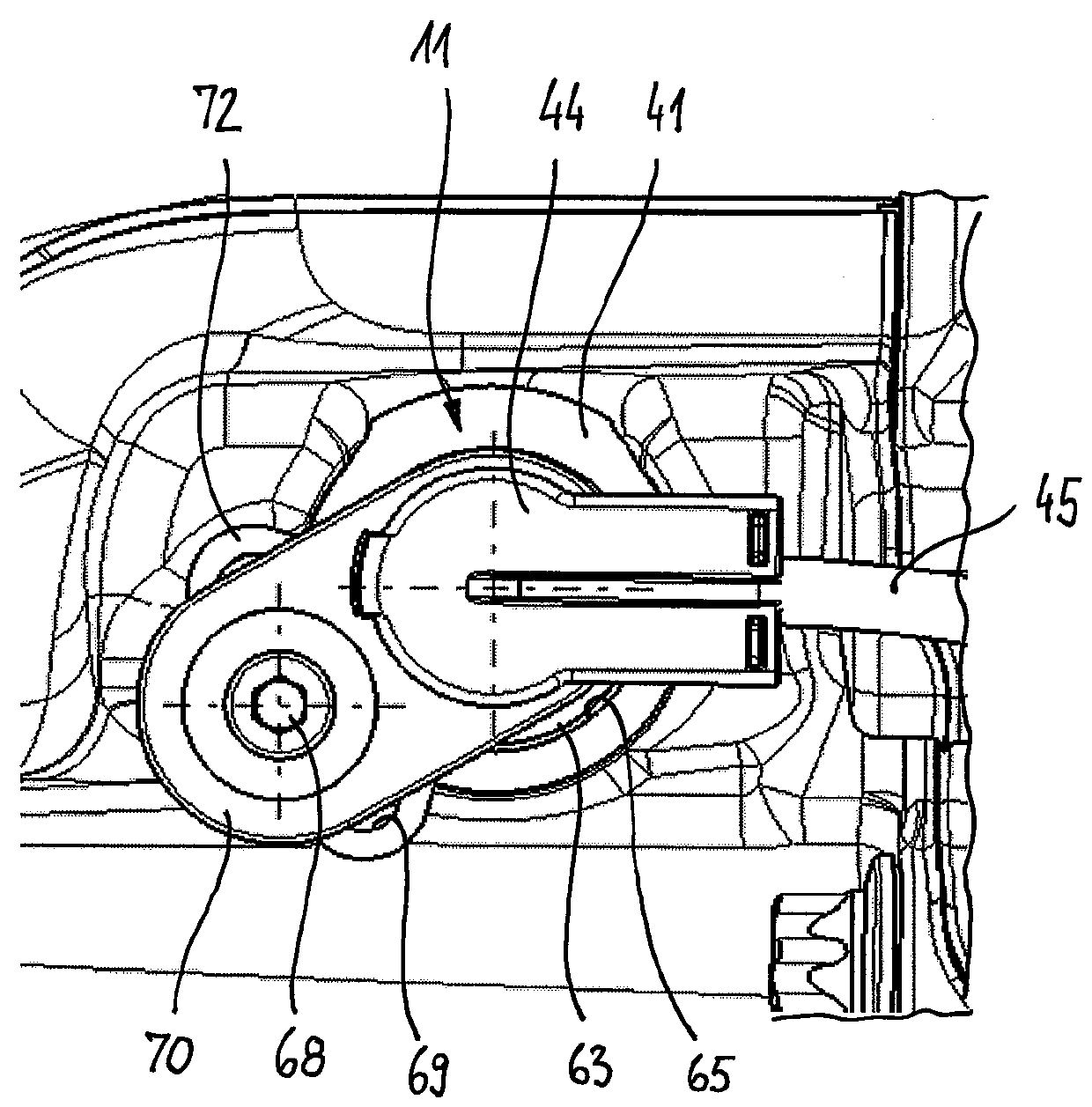

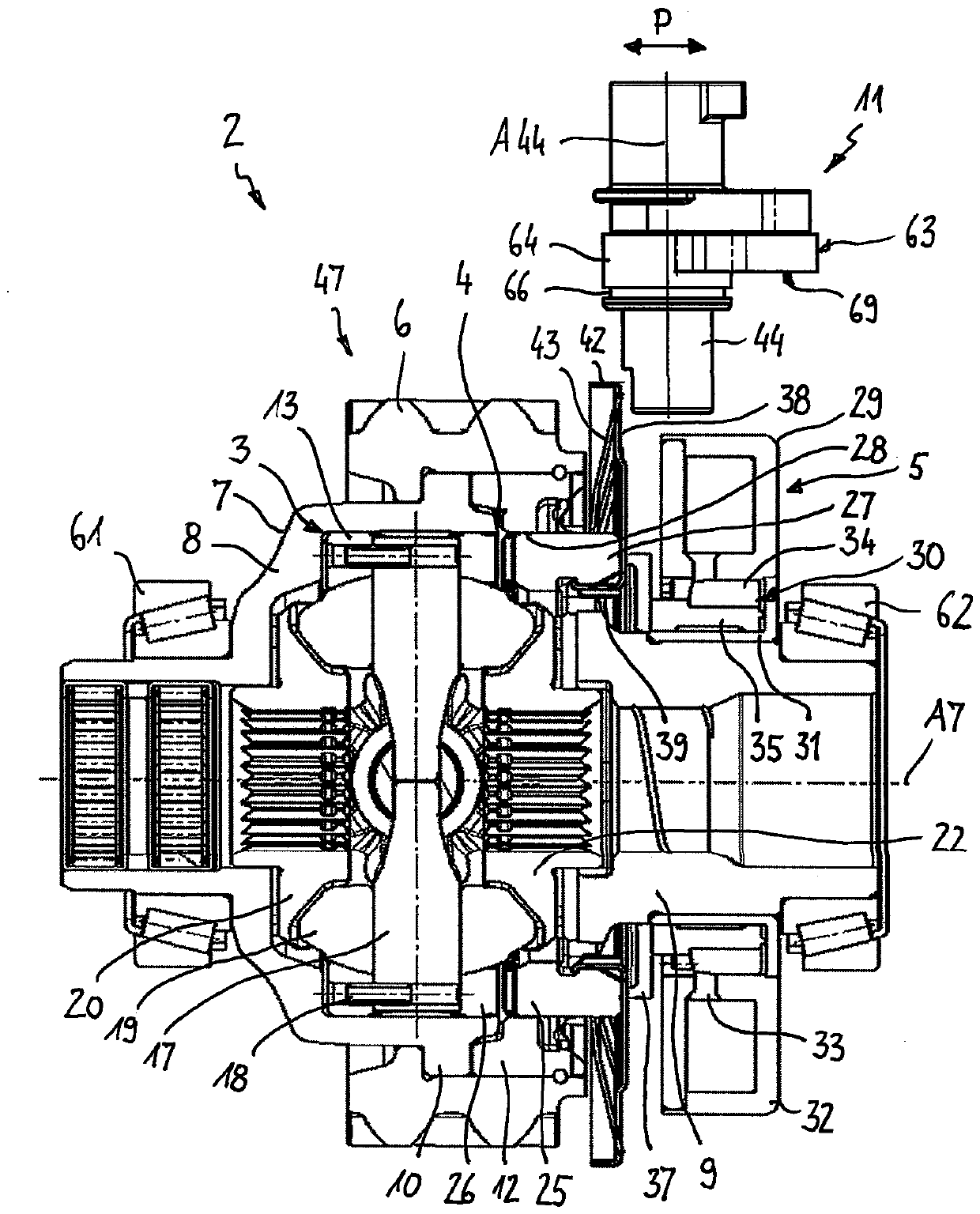

[0051] Figures 1 to 3 (which are described together below) shows a clutch pack 2 according to the invention in a first embodiment. The clutch pack 2 comprises a clutch 4 , an actuator 5 for actuating the clutch 4 and a sensor unit 11 . The clutch 4 can optionally transmit torque to the downstream transmission unit 3 in the power path. The gear unit 3 is designed in the form of a differential gear, but should not be restricted thereto. The clutch assembly 2 together with the transmission unit 3 , which together can also be referred to as a drive assembly 47 , is intended for use in the drive train of a motor vehicle, ie for distributing the introduced torque to two parts of the motor vehicle. on the two half shafts, wherein the torque transmission between the drive source of the motor vehicle and the half shafts can be optionally established or interrupted by means of the clutch 4 according to requirements. The clutch 4 is actuated by means of the actuator 5 , which acts on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com